Every year the nation spends about $8.3 billion, directly from the cost corrosion in our national highway bridges.

Figure 1: Annual Direct Cost [3]

Most of the highway bridges are concrete with steel reinforced rebar in their support structures. The leading corrosion cause in these bridges is the corrosion of the steel reinforcement. The most common form of this reinforcement corrosion is electrolytic due to migration of chloride ions to concrete enclosed steel rebar. The most feasible way to stop this corrosion is Cathodic protection using zinc as the active anode.

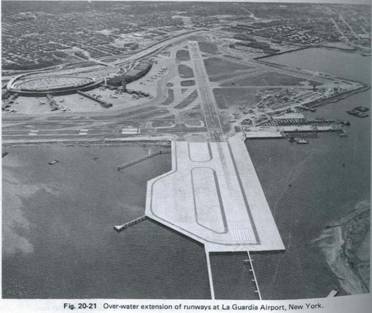

Foundations for houses, buildings, and bridges are some common applications for concrete. Low material cost (0.04$/kg) is one the major reasons for the prevalent use in construction as well as the adaptability of the composite for many kinds of applications. Low Environmental impacts have been added incentive for present popular use due to complete recycling of discarded material. The picture of the airport in the following figure is an example of the uses of concrete.

Figure 2: Floating

Concrete is a hard and

porous composite of cement, sand, aggregate, and gravel..

The selection of mixture proportions can be aimed to achieve optimum mechanical

behavior of the harden product. Selection can result in the change of the

strength, consistency, density, appearance, and durability. Concrete cement is a very compressively strong material after curing

and proper component mixture. It is proportionally has a compressive strength

15 times greater than its tensile strength. Here lays the need for tensile

mechanical strengthening in the concrete to broaden its applications and use. This

tensile strengthening is the major focus and most important aspect for analysis

the mechanical behavior of concrete cement composites. Hydration and

densification are the most common and necessary ways to strengthen concrete

cement composites. Temperature is another major factor in the hydration process

and the time needed for the cement to cure or harden (i.e. hotter faster,

colder slower). Compaction is the most important step in the densification of

the final concrete product. Vibrators, floating, and other surface finishing

techniques increase the densification of the concrete. This compaction or

densification reduces the amount of pores in the composite thus increases the

overall tensile strength.

One of the most prevalent materials in the

reinforcement of concrete is steel. The main reason is because of its high

tensile. A second almost as valid reason is that steel and concrete cement have

almost the same thermal expansion coefficient. This means that when

concrete/steel composite expands upon heating all the components of the

composite. To insure and strengthen the bonding in a concrete steel reinforced

composite the surface of the steel members are processed with the incorporation

of contours (or ridged) that is called rebar.

One major modern safety use of steel reinforcement in concrete is to prevent structure collapse upon brittle fracture of the cement matrix due to high cyclic tensile loading (i.e. earthquakes and wind). But what happens when our steel reinforcement fails (i.e. corrosion) from within causing the concrete structure to fail.

Environment

The environment is the leading factor in the cause of corrosion and resulting structure failure. When we consider concrete bridges and/or concrete parts of the bridge we need to think about the worst environments. For an example we can look at the following picture and consider the bridge structures environment: extreme temperature changes, water, river current forces, de-icing salt on bridge deck, road wear etc.

Figure 3: Bridge with Ice in Water [2]

This next picture we might consider the bridge structures environment: salt water, tidal current forces, salt-spray zone on bridge, road wear etc.

Figure 4: Bridge

in Sea Water [2]

Regardless the bridge, we can clearly state

that corrosion in concrete bridges is a result of the bridge’s environment.

Steel Rebar Reinforcement

Corrosion

The corrosion of the steel rebar

reinforcement is the most common source of distress in concrete bridges. We

find that this type of corrosion usually takes place on concrete structures

near or under water (e.g. bridges). In general the environment is fresh water

or salt water, thus an electrolyte solution perfect for corrosion.

When considering the initial state of the

reinforcement in our concrete bridges, we can state that the cement acts to

protect the reinforcement by passivating it. It forms

a protective oxide coating on the steel giving a pH of 13-14 adjacent to the

steel. The corrosion of the steel reinforcement occurs below pH 11. The pH of

seawater is about 8. We will consider the worst case for our environment in

relating the corrosion mechanisms, marine.

Mechanisms

The first thing to state is that carbonation

and chloride ions equal a lot of corrosion. The carbonation and chloride ions

diffuse through the concrete until the reach the embedded steel. Then the pH is

lower by the presence of the chloride ions.

This corrosion process also requires oxygen diffused through the concrete, set-up an electrochemical reaction. The process is increased by existence of voids in the concrete adjacent to steel.

Figure 5: Mechanisms of Corrosion [5]

The seawater can also diffuse through the

permeable concrete and evaporate, resulting in salt cells forming in the pores.

This can set-up a battery action with the steel, leading to electrolytic

corrosion. We will now briefly list general prevention and protection

techniques to apply to the concrete to retard these mechanisms of corrosion.

Prevention and Protection

1)

Dense impermeable concrete

2)

Adequate reinforcement cover

3)

Rich cement factor

4)

Salt-free aggregates

5)

Minimum chloride content in mixing water

6)

Proper type of cement mix

7)

Consolidation of cement around steel reinforcement

8)

Adequate curing (complete hydration)

9)

Coating applied to concrete surface and/or steel

10)

Allow no galvanic coupling by using other metals (i.e. copper &

aluminum) in the reinforcement.

We will just consider the most common and

cost effective advanced corrosion protection method: reinforcement coatings,

migrating corrosion inhibitors (MCI), and cathodic protection.

Some coatings that when applied to the steel before placed in the concrete that have shown some success in reducing the corrosion rate are epoxy coated rebar and hot dip galvanizing rebar.

MCI is also used with a get deal of success

when using low density concrete due to an easier path for the inward diffusion

of the MCI, resulting in faster corrosion retardation. MCI offers protection

for the steel rebar by using the inhibitors to suppress (raise pH) the chloride

ions.

Cathodic Protection is generally applied by

using zinc as an anode in a galvanic couple with the steel causing all the

corrosion to work only on the zinc. This corrosion protection method is the

most common, simple, and reliable for our concrete reinforcement corrosion. The

following figure shows the simple mechanics of this method.

Figure 6:

Zinc Anode

Attached to Steel Rebar [5]

This next figure given is an example of how we can apply this method from outside multiple concrete structures (i.e. vie attached wire).

Figure 7: Zinc Anode between Pilings [5]

We can clearly state by weighing the cost and design of cathodic (zinc) corrosion protection is one of the most feasible and reliable of all the tested corrosion protection methods.

In conclusion, we have outlined corrosion protection methods to prevent steel rebar reinforcement in concrete bridges. Our nation of concrete highway builders need to wake-up to the fact that poor corrosion protection equal poor concrete bridge design and failure. Just like the following advertisement is trying to impress on us.

Figure 8: MCI Advertisement [1]

We

succeed in our introductory purpose to summarize on concrete bridge corrosion

with a focus on steel rebar reinforcement corrosion as the main cause. We

talked about the corrosion environment, mechanisms, prevention

and protection methods. The most feasible way to stop this corrosion is

cathodic protection using zinc as the active anode. For the future we know that

we as a nation need to accept that corrosion must be more of an

forethought in our concrete bridge design and construction.

Acknowledgements

I acknowledge the following

instrumental people for their help:

·

Professor Mehmet

Sarikaya, thank you for putting aside your

schedule to meet with me and help focus my discussion about this topic and

materials and teaching this corrosion class.

·

I would also like

to thank the students of the ME 406 class, for

providing support in the oral presentations and overall good peer

pressure in class academics.

1 Article

Figure 8: MCI Advertisement

Periodical: Concrete

International Vol. 25, No. 2

Title: "Concrete Bridges"

Date: February 2003

2 Article

Figure 2: Bridge with Ice in Water

Figure 3: Bridge in Sea Water

Periodical: Concrete

International Vol. 24, No. 2

Title: "Concrete Bridges"

Date: February 2002

3 Article

Figure 1: Annual Direct Cost

Periodical: Materials

Performance

Title: "Migrating Corrosion Inhibitors for Steel Rebar in Concrete"

Author(s): Bezad Bavarian & Lisa Reiner

Date: February 2003

4 Article

Periodical: Materials

Performance

Title: "Permanent Corrosion Monitoring in New and Existing Reinforced Concrete Structures"

Author(s): John

P. Broomfield, Kevin Davies, & Karel Hladky

Date: July 2000

5 Book

Figure 4: Floating

Handbook of Concrete

Engineering 2nd Edition

Edited by: Mark

Fintel

Published: Van Nostranel Reinhold Copyright 1985

6 Publication

Figure 5: Mechanisms of Corrosion

Corrosion

of Metals in Concrete

Published: American Concrete Institute

Date: Copyright 1975

7 Publication

Figure

6: Zinc Anode Attached to Steel

Rebar

Figure

7: Zinc Anode between Pilings

Solving

Rebar Corrosion Problems in Concrete

Published: National Association of Corrosion Engineers

Date:

8 Publication

Concrete Sealers for

Protection of Bridge Structures Report 244

Published: Transportation Research Board

National Research Council

Date: December 1981

9 Publication

Underwater Bridge

Maintenance and Repair

Published: NCHRP Synthesis 200

National Research Council,