Embedding Tetrodotoxin in Elvax

June 1987

Thomas R. Pasic, MD

EQUIPMENT REQUIRED

A. Chemicals:

1. Dichloromethane 20-50 cc

2. Tetrodotoxin 1 mg

3. Elvax 2-5 gm

4. Distilled Water

B. Supplies:

1. Kimwipes

2. Parafilm

3. Test tubes (5)

4. Test tube rack

5. 1.5 ml Eppendorf tubes (5)

6. Vortex mixer

7. Metal spatula

8. Metal file

9. Glass graduated cylinder (50 cc)

10. Magnetic stirrer/Hotplate

11. Stirring magnet

12. Glass Erlenmeyer flasks (25 and 50 cc)

13. Glass pipette (10 cc)

14. Pipetteman (1000 ul)

15. Level, one-inch circular

16. Dry ice: two pounds of pellets and a 6 X 6 inch block

17. Gloves and lab coat

18. Glass Petri dish (3.4 cm diameter)

19. Scale to weigh Elvax

20. Timer

21. Small forceps

C. Equipment:

1. Lyophyllizer

2. Minus 20 degree freezer

3. Isolation hood

4. Minus 80 degree freezer (optional)

TETRODOTOXIN / ELVAX EMBEDDING

Introduction

1. Tetrodotoxin (TTX) is a highly toxic molecule first isolated from the puffer fish, Family Tetraodontoidae. Its mechanism of action is to block voltage-gated sodium channels. The opening of these channels is responsible for the rapid depolarization in the first phase of the action potential. Thus, TTX blocks action potentials and stops electrical activity of many excitable cells, including neurons (but not hair cells.)

TTX is obtained from Sigma chemicals (Cat. No. T6254.) It costs about $95 per milligram (including a $8.50 poison handling fee) and comes in a glass vial in crystalline form mixed with 5 mg of dry sodium citrate buffer at pH 4.8. It should be stored in the refrigerator until used. Safety measures are important since TTX can be absorbed through skin, and are included in the package insert.

2. Elvax: Elvax is a resin made from ethylene‑vinyl acetate copolymer. A small amount of the anti‑oxidant Butylhydroxytoluene (BHT) is added to prevent discoloration. Elvax with BHT is mildly inflammatory to tissues. However, if the BHT is removed Elvax is biologically inert. Removal of BHT (and other unnamed impurities) is done by serial washings with water, 95% ethanol and finally 100% ethanol at 37¡ C.

Elvax is obtained from DuPont. Our current supply was a free sample, Grade 40w, Lot 545891, from William Grant at DuPont (Tel. No. 1‑800‑441-9494 Ext. 272.) It is supplied as 0.025 gm pellets of clear "plastic" that can be disolved in solvent and poured into a mold. The solvent then evaporates leaving Elvax of any shape and weight.

3. Normal physiologic correlates of hearing include shear forces applied across stereocilia which modulate the conductance of cation channels in the hair cell. The conductance changes induce membrane potential changes (i.e., voltage changes) and neurotransmitter release from the hair cell. In turn, neurotransmitter induces voltage changes in first order auditory neurons and voltage gated-sodium channels open.

If TTX is placed on the round window membrane it is believed that the TTX will diffuse and bind to the sodium channels of the auditory nerve. By incorporating the TTX into Elvax, a controlled release form is made. The onset and duration of effect is dependent upon release kinetics and is monitored by the Auditory Brainstem Response (ABR.)

Reference: Langer, Robert, Larry Brown and Elazer Edelman. "Controlled Release and Magnetically Modulated Release Systems for Macromolecules, " in 'Methods in Enzymology' Volume 142, pp. 399-422. See especially Method 4 on page 404.

Method: Washing Elvax

1. Weigh a desired amount of Elvax on a balance. I wash 20 gm of Elvax at a time.

2. Place the Elvax in a beaker with 20 volumes of distilled water (200 cc dH20) and a magnetic stirring rod. Cover tightly with Parafilm.

3. Stir at 37¡ C for at least two hours per wash for five washes. The stirrer is placed in an oven to maintain the temperature. A flow sheet (included in protocol) is taped to the oven door to document times of each wash. Typically, two to three washes can be done each day plus one more wash overnight.

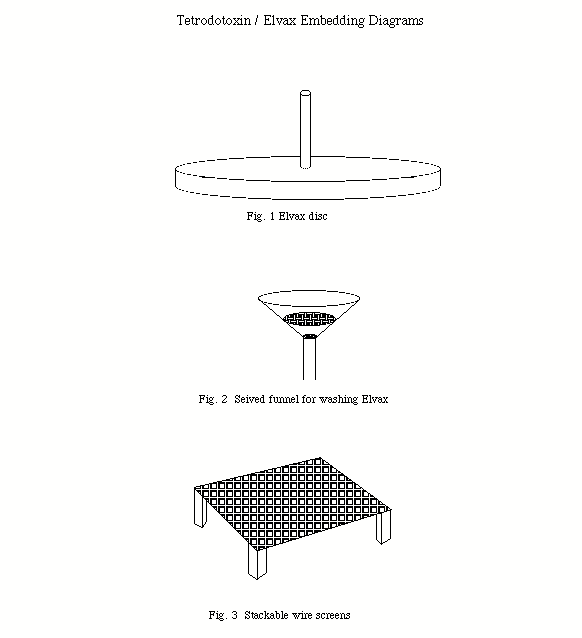

4. Wash with 95% Ethanol for ten washes at 37¡ C. I decant by pouring through a sieved funnel and save approximately ten cc's of each wash for spectrophotometric confirmation of BHT removal (see No. 7.)

5. In a similar manner, wash with 100% Ethanol for five washes at 37¡ C. Be sure that the Parafilm tightly covers the beaker or else the Ethanol will evaporate.

6. After all washes are completed, place the Elvax pellets in a Petri dish and dry in the oven overnight. Finally, place them in a sealed and labeled container.

7. The samples of wash solution, as well as controls, can be measured for absorpance at 230 nm in a spectrophotometer to assay for BHT. Langer reports that the initial readings may be 2‑3 units and the final readings should be less than 0.02 units.

Method: Sustained Release TTX

1. Dissolve washed Elvax in Dichloromethane (DCM; also known as Methylene Chloride) obtained from Fisher, Cat. No. D37‑500; a 500 cc bottle costs $13.30. Stir with a magnetic stirrer at 36¡ C for 60 minutes in a glass container with Parafilm covering the top. DCM will melt a plastic container. Use a 10:1 volume to mass ratio (e.g., 20 cc DCM to 2 gm Elvax.) Use the magnetic stirrer that is in the oven because the lowest setting of the stirrer heater boils the DCM (39.8¡ C.)

2. Cool a small Petri dish (3.4 cm diameter) by placing it on a block of dry ice. It should cooled for about 10 minutes before use. Line the dish with a Kimwipe to prevent ice from forming and make it level using a one inch circular level. Also cool a metal spatula and a razor blade on the dry ice for later use.

3. All work with free TTX is done under a hood wearing double gloves and a buttoned lab coat. Do not close the hood door very far because air currents blow the TTX crystals about. Score the TTX vial with a file before opening then snap off the top. Place the larger TTX crystals in a small test tube and wash out the remaining crystals with a small amount of distilled water. Be careful to use a measured amount of water that is less than the total amount of water required. The total amount of water used is 15% of the final combined volumes of water and DCM, as follows:

Water/(Water + DCM) = 0.15

Volumes that I have used are in the table. The water loading (in percent) of the Elvax is a variable that can be manipulated to achieve preferred release kinetics.

4. Pipette Elvax/DCM solution into a test tube using a glass graduated pipette and a suction bulb.

Pipette TTX/Water solution into same test tube using a Pipetteman.

Vortex on speed 10 for sixty seconds.

5. Without delay, pour the suspension onto the cooled and leveled glass Petri dish. Freeze for 10 minutes on dry ice. Cover the suspension with a Kimwipe for last 7 minutes of freezing.

6. Using the metal spatula cooled on dry ice encircle and remove the TTX/Elvax disc. Quickly notch the disc with the cooled razor blade for identification. Then place the disc on a cooled wire screen in a minus 20¡ freezer for 2 days. The wire screens and discs should be clearly labeled as poisonous in the freezer. The DCM will evaporate over this time leaving only Elvax, TTX and water.

7. The glass containers that had the DCM/Elvax solution in them will have a film of Elvax in them that is difficult to clean. I have found that washing with warm DCM aids in cleaning.

8. After the two days, transfer the discs to a lyophyllizer for 2 to 20 days to achieve preferred release kinetics. Longer times should result in faster release of TTX. I lyophyllize for 4 to 5 days along with a 1 cc ice bullet to confirm that the vacuum is maintained. A lyophyllizer is a freeze‑drier that runs at less than ‑85¡ C and less than 30 milli‑Torr. The object is to remove the water that is embedded in the discs leaving only Elvax and TTX. Cool the lyophyllizing flask in dry ice pellets for 30 minutes before placing the discs in the flask. Then, transport the flask which is still surrounded by dry ice pellets to the lyophyllizer. Place the flask on the lyophyllizer and engage the vacuum. Be sure to watch that the vacuum equilibrates to a pressure less than 30 milli‑Torr.

9. After lyophyllizing is complete, remove the flask and place the discs in a vacuum bottle, draw a vacuum (to decrease the partial pressure of water) and put the bottle in a freezer.

10. At least one hour before the TTX is needed, remove the vacuum bottle from the freezer and let thaw. Cut out plugs of TTX embedded Elvax from the central portion of the disc using a stub adaptor. I soak the plug for 5‑ 10 minutes in a small puddle of distilled water before implanting to start disolving the TTX. A 17‑gauge stub adaptor make plugs that fit well into the round window antrum of the gerbil. The weight of a single 17‑gauge plug is about 0.5 mg. The thickness of the disc (which is determined by the diameter of the small Petri dish mold) is an important variable of the TTX dose.

Table

| Elvax (gm) |

DCM (cc) |

Water (cc) |

TTX (mg) |

Water/Water +DCM (%) |

|

| 1 |

0.5 |

5.0 |

0.88 |

0.25 |

0.149 |

| 2 |

0.5 |

5.0 |

0.88 |

0.50 |

0.149 |

| 3 |

0.25* |

2.5 |

0.44 |

0.50 |

0.149 |

*A smaller mold was used to create a disc with the same thickness as the first two.

Appendix: Variables affecting release rate:

1. Drug loading‑‑additional drug increases rate of release.

2. Water loading‑‑additional water increases rate of release.

3. Crystal Size‑‑if the TTX was not first put into solution, increasing size of the TTX crystals increases rate of release. The size of the water droplets in the Elvax/ TTX suspension is the likely analogous variable.

4. Lyophyllizing time‑‑ longer lyophyllizing increases rate of release.

5. Molecular weight‑‑ increasing MW decreases rate of release. The moleculat weight of TTX is 319.

6. Carrier molecules‑‑ adding a carrier such as albumin to the Elvax increases rate of release of the molecule of interest.

ELVAX WASHING FLOW SHEET

| Water |

95% Ethanol |

100% Ethanol |

|||

| 1. |

1. |

1. |

|||

| 2. |

2. |

2. |

|||

| 3. |

3. |

3. |

|||

| 4. |

4. |

4. |

|||

| 5. |

5. |

5. |

|||

| 6. |

|||||

| 7. |

|||||

| 8. |

|||||

| 9. |

|||||

| 10. |

|||||

Revised 9/85

Safety Data Sheet

TETRODOTOXIN

WARNING: These products are to be handled only by qualified professionals familiar with the properties and potential dangers of Tetrodotoxin.

A. Hazard

According to literature,1-4 Tetrodotoxin is among the most toxic substances known to man; death can occur within 30 minutes. The toxin is extremely dangerous by ingestion, inhalation, skin absorption, or if it enters the blood stream in any manner. Symptoms of poisoning, which include numbness, tingling of the lips and inner mouth surface, weakness, paralysis of the limbs and chest muscles and a drop in blood pressure, have been reported within as little as 10 minutes after exposure.

B. Handling

At Sigma, Tetrodotoxin is only handled in closed systems. All operations are carried out in a glove bag or other enclosures to avoid accidental contact. Personnel are required to wear disposable clothing, including gloves, long-sleeve coveralls with tight collar and cuffs and shoe covers. Air is supplied by an independent system. Our company doctor is notified before we work with these compounds so that he is prepared in the event of an emergency.

C. Decontamination

a) Broken packages are securely repackaged by personnel wearing and using appropriate equipment and then incinerated in a government approved incinerator. b) Spills: Cover with absorbent and collect in safe container for incineration. c) Disposal: Toxin can be detoxified by prolonged boiling, or by treatment with strongly acidic or strongly basic (alkaline) solutions.

D. Exposure

Contact your physician at once (See above paragraph B) and inform him that you have been exposed to Tetrodotoxin. If numbness occurs, start artificial respiration and continue until medical help arrives.

E. Storage

Tetrodotoxin is stored in a tightly closed mailing tube or metal can at 0-5¡C.

(Over)

SIGMA CHEMICAL CO., P.O. BOX 14508, ST. LOUIS, MO., 63178 U.S.A.

9/85

References

1. Fuhrman, F.A., Scientific American, 61-71, 1967, Tetrodotoxin.

2. Lalone, R.C., DeVillez, E.D., and Larson, E., Toxicon, 1,159-164,1963. An Assay of the Toxicity of the Atlantic Puffer Fish, Spheroides macutatus.

3. Mosher, H.S., Fuhrman, F.A., Buchwald, H.D., Fischer, H.G., Science 144,1100,1964. Tarichatoxin-Tetrodotoxin:A Potent Neurotoxin.

4. Borison, H. L., McCarthy, L.E., Clar, W.G., and Radhakrishnan, N., Toxicology and Applied Pharmacology 5, 350-357, 1963. Vomiting, Hypothermia, and Respiratory Paralysis Due to Tetrodotoxin (Puffer Fish Poison) in the Cat.

5. July 1985 Registry of Toxic EHects of Chemical Substances, U.S. Department of Health, Education and Welfare, Public Health Service, Center for Disease Control, National Institute for Occupational Safety and Health, Cincinnati, Ohio 45226.

#IO 1450000:

TOXICITY AND DATA REFERENCES:

unr-rat LDLo: 15 uglkg SCIEAS 144,1100,64

orl-mus LD50: 435 ug/kg JJPMZ 17,267,67

ipr-mus LD50: 8 ug/kg SCIEAS 144,100,64

scu-mus LD50: 8 ug/kg CTOXAO 4,331,71

ivn-mus LD50: 9 uglkg JJPMZ 17,267,67

unr-mus LD50: 10 uglkg CTOXAO 18,813,81

unr-frg LDLo: 15 uglkg SCIEAS 144,1100,64

TOXICOLOGY REVIEW TRBMAV 33(1),183,75

SIGMA warrants that its products conform to the information contained in this and other Sigma publications. See reverse side of invoice or packing slip for additional terms and conditions of saie.

Satisfaction is always guaranteed when you use SIGMA Reagents.

P.O. BOX 14508, ST. LOUIS, MO., 63178 U.S.A.