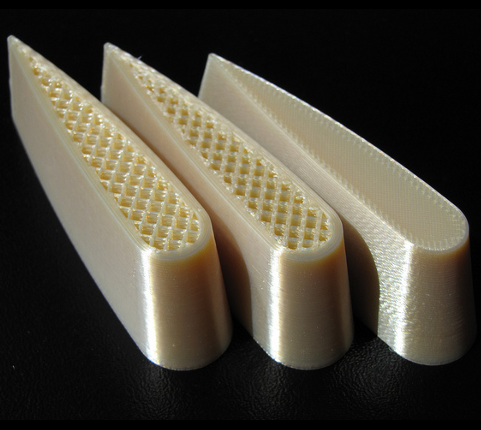

ULTEM 9085 is a high strength thermoplastic that is certified by the Federal Aviation Administration (FFA) for additive manufactured (AM) parts. This qualification was conducted by the National Institute for Aviation Research (NIAR) and analyzed by the National Center for Advanced Materials Performance (NCAMP). The qualification data includes mechanical properties such as tensile and flexural loading as well as physical & chemical properties such as flammability and moisture loss. The goal of our current study is to analyze the NCAMP database to find abnormal performance and develop testing plans to explore these findings. The initial testing conducted last year focused on tensile properties of ULTEM 9085 and exploring how build orientation effects the density of parts and interlayer bonding. The testing that is currently being conducted explores different geometries and ASTM testing procedures for compression, V-notch shear, and single shear bearing coupons. The goal of this testing is to produce more appropriate failure modes. Along with this further tensile testing is being conducted exploring the effect that the number of contours have on the mechanical properties of different build orientations. Further testing later this spring plans on developing a machine learning model to predict the stress strain curve based on process parameters such as infill percentage, raster angle, and build orientation.