|

Producing silk was a lengthy, complex process. As show

in the illustrations below, men took responsibility for the mulberry

trees, growing the only food silkworms eat, but women were responsible

for the critical task of feeding the leaves to the silkworms. Silkworms do not spin cocoons on demand; timing and

temperature have to be handled carefully, and during the month between

hatching and spinning the cocoons have to be fed every few hours, day or

night. If properly coddled, the worms eventually spin cocoons for

several days, each cocoon made up of a strand of silk several thousand

feet long. Over two thousand silkworms are needed to produce one pound

of silk.

The illustrations below of the steps in the sericulture process are

from a set issued by the government in the late seventeenth

century. The tradition of the government sponsoring sets of

pictures of the processes involved in both agriculture and silk

production dated back to Song times. It was based on the view that

the government should encourage basic, productive work, as

opposed to less essential enterprises such as trade.

|

The sericulture process begins with washing the silkworm eggs that

had been stored over the winter.

|

|

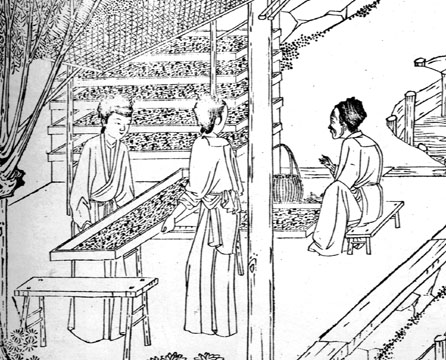

After the eggs have hatched, the larvae are spread out on trays to

grow. They are fed chopped mulberry leaves for about a month.

Why do you think a baby and small child are in this picture? |

| Below, women bring baskets of mulberry leaves during the

final few days before the worms spin their cocoons. At this point,

the worms may need to eat ten times a day. |

|

|

The rushes on the trays have to be cleaned regularly.

|

|

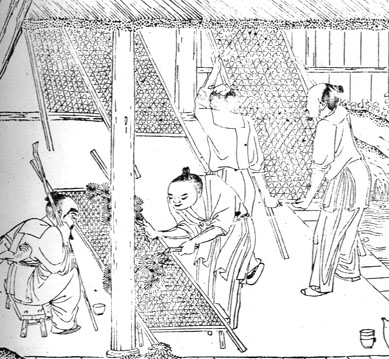

Preparing the frames for the silkworm mats, where the worms will be

placed for spinning. |

|

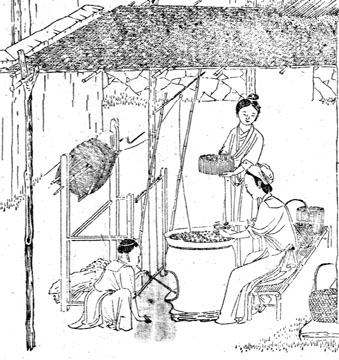

Spinning may take about a week, after which the cocoons have to be unraveled.

Here the cocoons are in a pot of hot water, which both kills the worms

and loosens the filaments

and lets the cocoons float freely. The filaments from several

cocoons are reeled off together to make a strong thread. |

|

To

make stronger warp threads, it is necessary to twist several single

threads together on a spooling frame. To

make stronger warp threads, it is necessary to twist several single

threads together on a spooling frame. |

|

Silk threads are wound onto smaller reels for weaving.

|

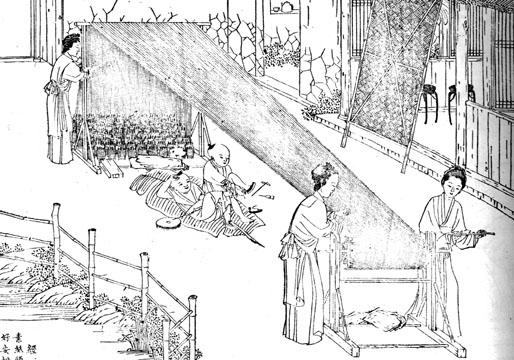

| In preparation for weaving, the warp threads are laid out

and rolled up. |

|

| Below, the skeins of silk are being dyed.

Do

you think this is done in each household, or by specialists?

|

|

|

| SOURCE:

Dyeing was commonly done by specialists for a fee. Dyeing

was a messy business, and not of high status. |

|

For simpler weaves, one woman could operate a treadle loom, using her

foot to raise the heddles.

How would you compare the work involved in weaving to all of the

earlier steps in making silk yarn? Which took longer, was more

tedious, more creative? |

|

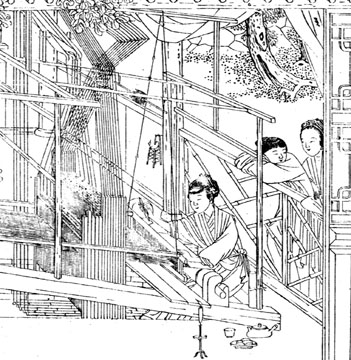

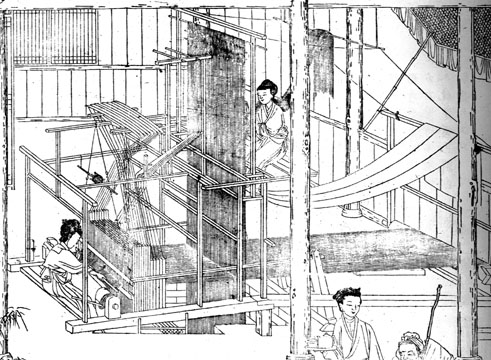

More complex weaves required a two-person draw loom.

The person perched above moves the heddles that allow the weaving of

complex multi-colored patterns.

|

| SOURCE:

Yuzhi gengzhi tu (Taibei: Guoli Gugong bowuguan,

1979 reprint of 1696 ed.), passim. |

|

|