Characterization and Degradation of Crumb Rubber

Across the United States, many college-level athletic fields consist of an artificial turf surface composed of synthetic grass fibers, silica, and a crumb rubber infill. When under typical operating conditions, the crumb rubber is exposed to ultraviolet (UV) radiation, temperature fluctuations, and mechanical wear. The primary purpose of the crumb rubber in sports fields is to cushion physical impacts that may occur on the field while withstanding the environmental elements. The goal of this research is to understand the degradation mechanisms of the crumb rubber when exposed to these conditions and replicate them, in part, in the Materials Testing and Characterization Laboratory (MTCL) at the University of Washington Bothell. This will be achieved by performing accelerated weathering using a UV environmental degradation chamber. Analytical techniques, such as Fourier Transform Infrared Spectroscopy (FTIR), mass percent composition, and scanning electron microscopy (SEM) will be utilized to quantify and determine chemical and morphological differences in samples across different locations and periods.

Student Outcomes

- Learning various testing protocols and the collection of test data over time to further scientific knowledge and to provide recommendations to the manufacturers and customers of crumb rubber products.

- To become exposed to emerging materials tests including SEM, FTIR, XES (X-Ray Emission Spectroscopy), and accelerated degradation through UV radiation monitoring.

- The opportunity to coauthor conference and journal articles while maintaining a lab.

Project Details

Methods:

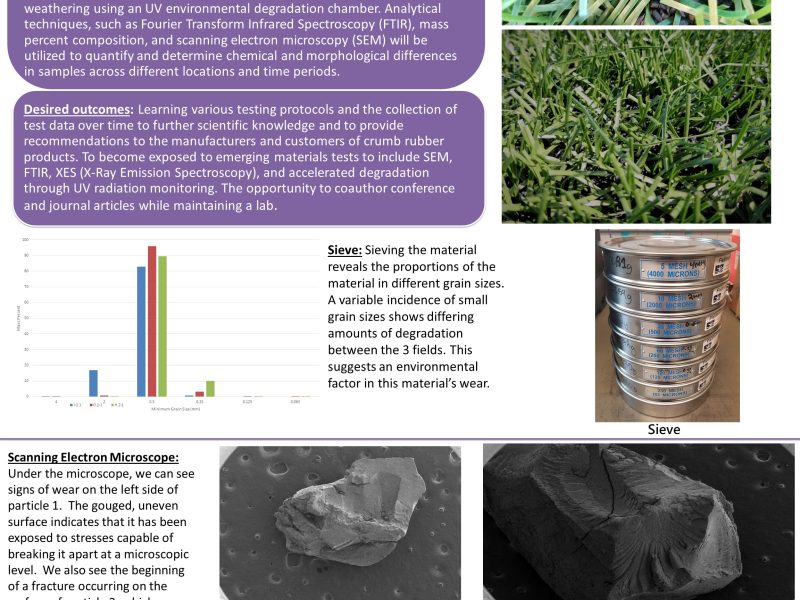

- Sieve – Sieving the material reveals the proportions of the material in different grain sizes. A variable incidence of small grain sizes shows differing amounts of degradation between the 3 fields. This suggests an environmental factor in this material’s wear.

- Scanning Electron Microscope-Under the microscope, we can see signs of wear on the left side of particle 1. The gouged, uneven surface indicates that it has been exposed to stresses capable of breaking it apart at a microscopic level. We also see the beginning of a fracture occurring on the surface of particle 2, which creates the smaller particles found using our sieve.

- Fourier Transform Infrared Spectroscopy -FTIR was run sing a Germanium crystal to counteract interference caused by carbon black.

We then integrated the area of significant peaks. In this case, the peaks from wavenumber 2600 – 3200 were integrated over a baseline to return an area that indicates the proportion of that material in the given sample. Our samples, all from different environments, show different amounts of material, suggesting different levels of degradation.

Students will:

- Conduct testing using XPS and Raman spectroscopy,

- Design and conduct hardness testing,

- Assimilate data into scientifically sound conclusions.