Compressed Gas Cylinders and Fire Safety

Reports have shown that gas cylinders used in CNG service have performed safely over many years and miles [1]. Review of cylinder accidents indicates failures do occur from service/maintenance-related issues (tanks damaged in impacts, corrosion) and component failures. In addition, vehicle burn tests of hydrogen and CNG cylinders with proper pressure relief devices have shown safe behavior in the event of fire [2].

There are four types of compressed gas cylinders used in vehicles. Each of these has characteristic failure modes [3]:

| Type 1: | All-metal cylinders made of steel or aluminum. |

| Type 2: | Steel or aluminum liners with a hoop-wound composite wrapping. The metal liner is designed to withstand pressure 25% above the service pressure. |

| Type 3: | Thin metal liner and composite overwrap. |

| Type 4: | A non-metallic liner with a composite overwrap. |

Metal cylinders have high impact and fire resistance but are subject to corrosion. Composite materials are lighter weight, often have good fatigue resistance and resistance to environmental damage (corrosion) but are at higher risk of impact and fire damage.

When inspecting a gas cylinder for damage, the factors to consider include:

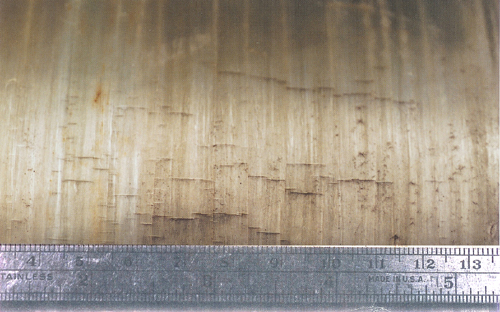

Surface pitting and corrosion of steel cylinders: Corrosion and pitting can reduce surface thickness leading to loss of integrity. [3] |

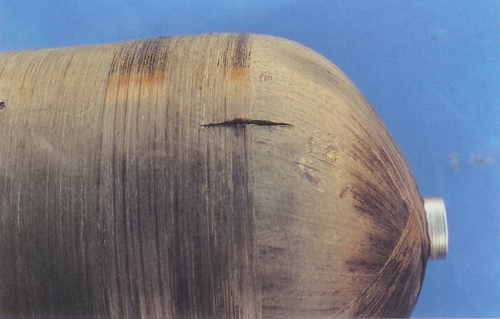

Fiberglass wrap with stress corrosion cracking, likely due to exposure to solvents. [3] |

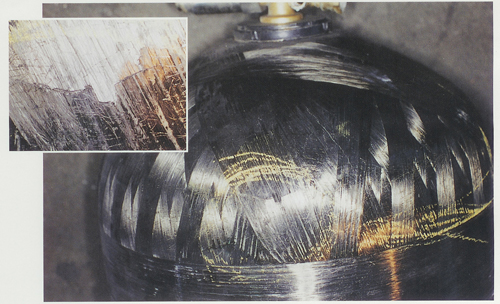

Structural integrity of a fully wrapped cylinder is particularly sensitive to surface cuts. [3] |

Impact and scuff damage to the surface of a cylinder with carbon composite wrap construction may indicate greater damage to the cylinder wall. [3] |

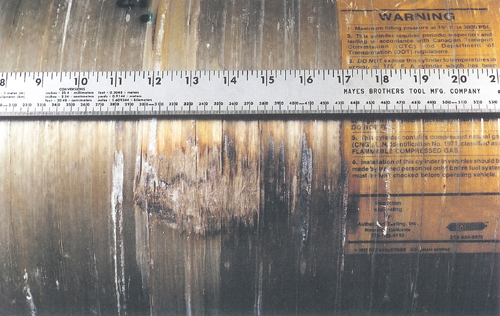

Brackets that are loose or missing gaskets can lead to wear or abrasion, as on this composite wrap cylinder. The cylinder was also subject to heat damage during the removal of a strap. [3] |

For more detailed information about visual inspection and care of CNG cylinders, see [3].

References

Photographs on page courtesy of Gas Technology Institute.