|

|

Detection: Methods

There are sensors based on heat, radiation and fumes that are designed to detect fire. Available sensors include:

Thermal sensors: Heat is detected directly in specific locations (spot detectors) and along the length of wires designed to activate when exposed to heat (linear detectors) [1]. Spot detectors are sensitive to fire in a small area; many are typically installed to sufficiently protect an engine compartment. Linear detectors can be many feet in length and strung throughout the engine compartment to detect fire around components with complicated geometry. Both spot and linear sensors require cleaning to prevent contamination and insulation from mud and debris.

|

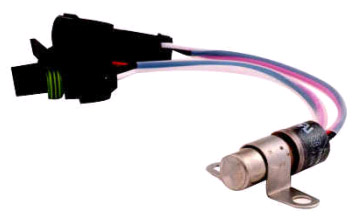

| An example of a thermal spot detector. [2] |

|

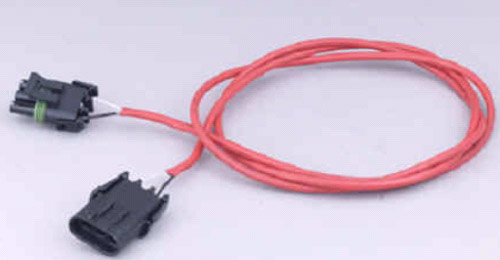

| An example of thermal linear detector cable. |

|

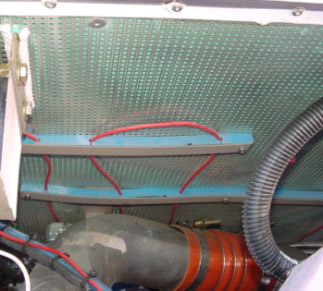

| A linear detector (arrow) mounted on the ceiling of an engine compartment. The wire is routed throughout the engine compartment to enhance early detection. |

Radiation sensors: Radiation sensors are generally designed to detect specific frequencies of light characteristic of fire; they are effective at locations remote from the fire if the sensing element is in the field of view of the fire. Various sensors use infrared, ultraviolet visible or a combination of spectra. If not cleaned during maintenance, the sensitivity can be muted, preventing detection or increasing the time to detection.

|

| An optical infrared sensor used in transit bus fire detection systems. |

|

| The same optical detector mounted in a CNG engine compartment. |

References

|

|

|