People - Students - Cohort 1 - Kenneth Faires

Kenneth Faires

Education: BS, Mechanical Engineering 2002 North Carolina

State University; MS, Mechanical Engineering 2003 Naval Postgraduate

School

Work Experience: More than 4 years of experience as a

naval officer working as an engineer, maintenance manager, and tactical

team leader

Major: Mechanical Engineering

Advisor: Joyce Cooper

Title of Research Project: Super critical

water gasification reliability and scalability

Context of research: My research is aimed ultimately

at helping to alleviate the energy shortage. Biomass is currently a

waste byproduct in many parts of the world. In the US thousands of tons

of yard waste and underbrush are disposed of every year. According to

some studies the energy content/quantity is high enough to entirely

replace gasoline consumption in certain geographical regions. The goal

of my research is to delve into a means of converting biomass into a

more useable fuel, mainly hydrogen. Current methods of biomass to energy

conversion focus primarily on standard gasification and simple combustion.

Both methods require drying, resulting in decreased system efficiency

and increased cost. Additionally, standard gasification tends to not

be overly selective in syngas production. It is my hope that by using

SCW gasification, a fuel that can be utilized directly by fuel cells

will result in improved system efficiency.

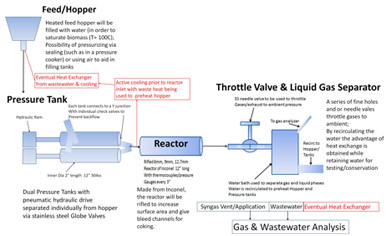

Supercritical water gasification is a form of gasification in which the reactor is pressurized and the temperature balanced so that water inside the biomass is at or above its critical point. This process is ideal for wet biomass containing as much as 90% water and yields a carbon build-up to <5% (per kg). Temperatures can range from 650k to 1000k with pressures on the order of 20-35MPa, although typical operating conditions are 700-800k at pressures near 25 MPa.

SCW has a number of advantages that make it preferable over other processes.

The gaseous phase products are “water scrubbed” resulting in a low particulate

high quality gas. The process is also very robust in that a large variety

of biomass can be used. In regards to cost, two of the most financially

draining requirements of other processes, drying and catalysts, are

entirely removed. The graph below illustrates the costs with respect

to hydrogen production of the currently available methods.

Research plan:

- Develop the capacity to perform experimental investigations of fuel and hardware performance for supercritical water gasification.

- Integrate design, performance, reliability, and scalability analyses into Life Cycle Assessments of supercritical water gasification systems

- Contribute to the development of this technology but also to Life Cycle Assessment methodology.

- Construct an actual gasification system and experiment on parameters such as temperature, pressure, feed rate, reactor size, reactor shape, etc.

- Monitor Syngas quality and makeup in order to determine optimal operating parameters for processing of various feedstocks.

Broader impacts of research: Syngas in and of itself

is useful as a fuel for various niche type uses (fuel cells, rocket

engines, etc). If coupled with other process such as the Fischer-Tropsch

or some of the Shell conversion processes, syngas can be converted into

a high-quality gasoline or diesel product that is directly useful to

current transportation systems.