Ongoing research projects:

1) Application of Cellular Core Technology as Novel Tooling for Innovative Composite Structure Development

Understanding the processing and properties of complex composite structures developed using a cellular core technology as inner tooling. The process was developed by inVision Composites and with them we work to better understand and define the abilities and advantages of using this novel tooling. The goal is to utilize this tooling to create more complex and integrated structures free of bonding or fasteners but with the necessary internal framework for load bearing, thereby making parts lighter and stronger.

Contact: Curtis Hickmott

2) Interpenetrating Polymer Network (IPN) Adhesive

Develop and characterize an adhesive system that utilizes interpenetrating polymer networks to improve toughness. This involves exploring bulk properties such as fracture toughness, tensile strength and glass transition temperature as well as properties at interfaces with particles, fibers or bonding adherends. Property variations will be tied to fundamental engineering principles which govern the network formation.

Contact: Gary Weber

3) Witness coatings for damage detection in aerospace composite parts

We are modifying traditional aerospace coatings by adding customized fluorescent dyes which are sensitive to local conditions such as stress or damage from impact, lightning strike, etc. We explore the mechanical, thermal, optical, and mechanochromic properties of the coatings with an eye towards optimizing state-sensitive fluorescent coatings for commercial and military aerospace applications.

Contact: Ryan Toivola & Tucker Howie

4) Surface characterization of aerospace composites for adhesive bonding

Surface characterization methods include contact angle measurements, scanning electron microscopy, Fourier transform infrared spectroscopy, and x-ray photoelectron spectroscopy. Characterization is related to bond strength and durability to understand the fundamental theory of adhesion.

Contact: Ashley Tracey

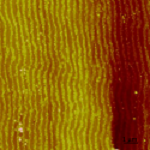

5) Mechanical behavior of nanolaminate alloys

Novel Cu-Ni nanolaminate materials for structural applications are fabricated via electrodeposition. Through in-situ atomic force microscopy (AFM) bend testing as well as SEM fractography the deformation and fracture mechanisms of these materials will be examined. Fracture mechanisms will be compared to the microstructure and mechanical properties. The effects of layer thicknesses and compositions will be tested.

Contact: Dana Rosenbladt & Irene Wang

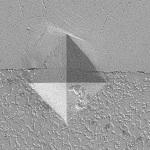

6) Friction stir welding of titanium alloys

Friction stir welding and diffusion bonding are high-integrity solid-state joining processes frequently used by aerospace to fabricate titanium structures. Characterization of the chemical composition and microstructure that results when joining two different titanium alloys together is being done with optical and electron microscopy in an effort to model the structure-properties relationship throughout the various zones of the joint.

Contact: Todd Morton & Tamar Sisneros