Manufacturing Capabilities:

-

600 square foot laboratory space with fiber optic draw tower, optical table, closed and open fume hoods for polymer processing.

-

Full range of fiber production

capability starting with preform fabrication through fiber drawing.

-

Draw speeds from 1 mm/sec to 1

m/sec. Fiber diameters from 50 to 1500 microns

with single draw. Sub-micron diameters possible with multiple draw

process.

-

Step index, multi-clad fiber

production. Fibers of non-circular cross section, such as elliptical, can also be fabricated.

Characterization Capabilities:

Fiber characterization capability

includes refractive index profile measurements using a reflection method with 3-axis translation stage. Standard

cutback technique is used for attenuation measurements.

Equipment:.jpg)

-

A Marshall Furnace with processing temperatures up to

420 +/- 0.5 C.

-

Beta diameter gauge capable of measurements +/- 0.5

microns.

-

9-position thermal array.

-

Labview controlled feed and draw motors.

-

2 preform curing furnaces.

Preform curing furnace.

Additional Equipment:

-

A Phoenix Beta Wet Grinder/Polisher controllable up to

500 RPM.

-

A chemical fume hood, a chemical fire extinguisher, an eye wash station, easy access to a chemical shower.

-

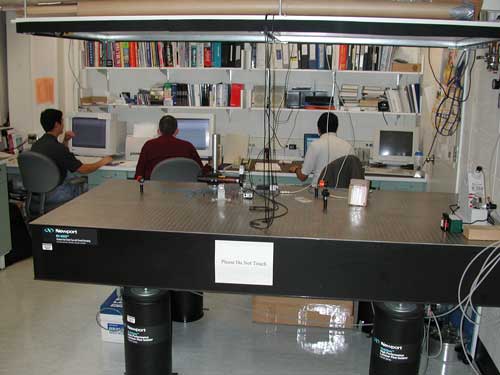

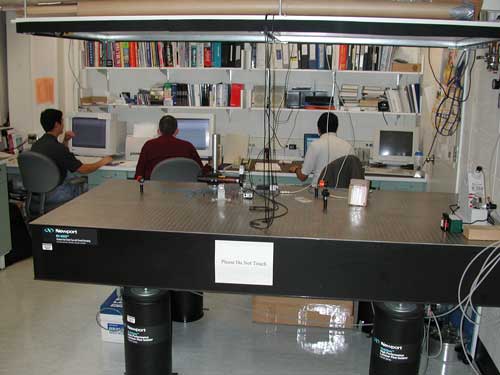

A Newport RS-4000 Optical Table.

|

.jpg)