| Components | |||

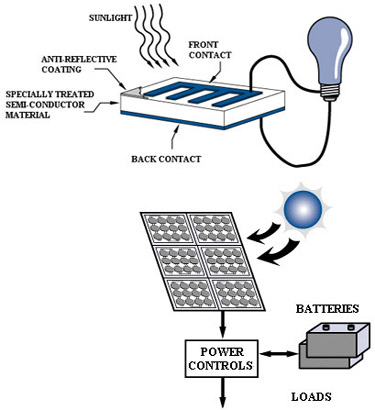

| Photovoltaics use crystalline silicone cells (about three inches across) connected in a series with solder and foil and placed under glass to form a panel. Arrays of panels range in size from one foot square to two-by-four feet square and only a few inches thick. Panels are rated based on their electrical output under Standard Test Conditions (1,000 watts/m{\fs16\up62} insolation and cell temperature of 25 Celsius/77F). Power is stored in dry-cell batteries for output at night or on cloudy days. Panels and batteries need protection from voltage extremes, and inverters are required to operate AC appliances since solar panels produce a DC current. Site-specific insolation, PV-cell output, battery characteristics and load requirements must all be coordinated for an effective system (Sorvig, p. 30). | |||

|

|||

| Figure 1: Transformation from sunlight into energy (www.fsec.ucf.edu/-pv/pvs_s1.htm) | |||

| Silicon is the most popular solar-cell material for commercial applications because it is readily abundant (it is the second most common element in the Earth's crust). To be useful in solar cells, however, silicon must be refined to 99.9999% purity. In the case of single-crystal silicon, the entire structure is grown from the same or a "single" crystal; its molecular structure is therefore uniform. This uniformity is ideal for efficiently transferring electrons through the material. | |||

| Semi-crystalline silicon, on the other hand, consists of several smaller crystals or grains separated by "boundaries." These boundaries impede the flow of electrons and encourage them to recombine with holes; they therefore reduce the power output of the cell. Semi-crystalline silicon is much cheaper to produce than single-crystalline silicon, however, so researchers are working on ways to minimize the effects of the grain boundaries. |

|||

|

|||

|

|||

| Thin film cells are a newer technology that, unlike crystalline cells, are not produced by slicing silicon crystals or blocks into thin wafers, and can be made with elements other than silicon. Thin film cells are formed by depositing a liquidized semiconductor material directly onto plastic, glass, or stainless steel substrate. Silicon, copper indium diselenide, or cadmium telluride are the semiconductor materials most commonly used in thin film technology. | |||