Pushing the Boundaries of Composite Additive Manufacturing

Additive manufacturing (AM) is hailed for freedom in complex component design and low material waste. Originally conceived for thermoset based stereolithography, all classes of materials are now being exploited and produced in tandem with additive processes to push the possibilities of engineered structures. Excitingly suitable for this field are fiber reinforced thermoplastics, which can offer incredible strength within lightweight and recyclable multiscale

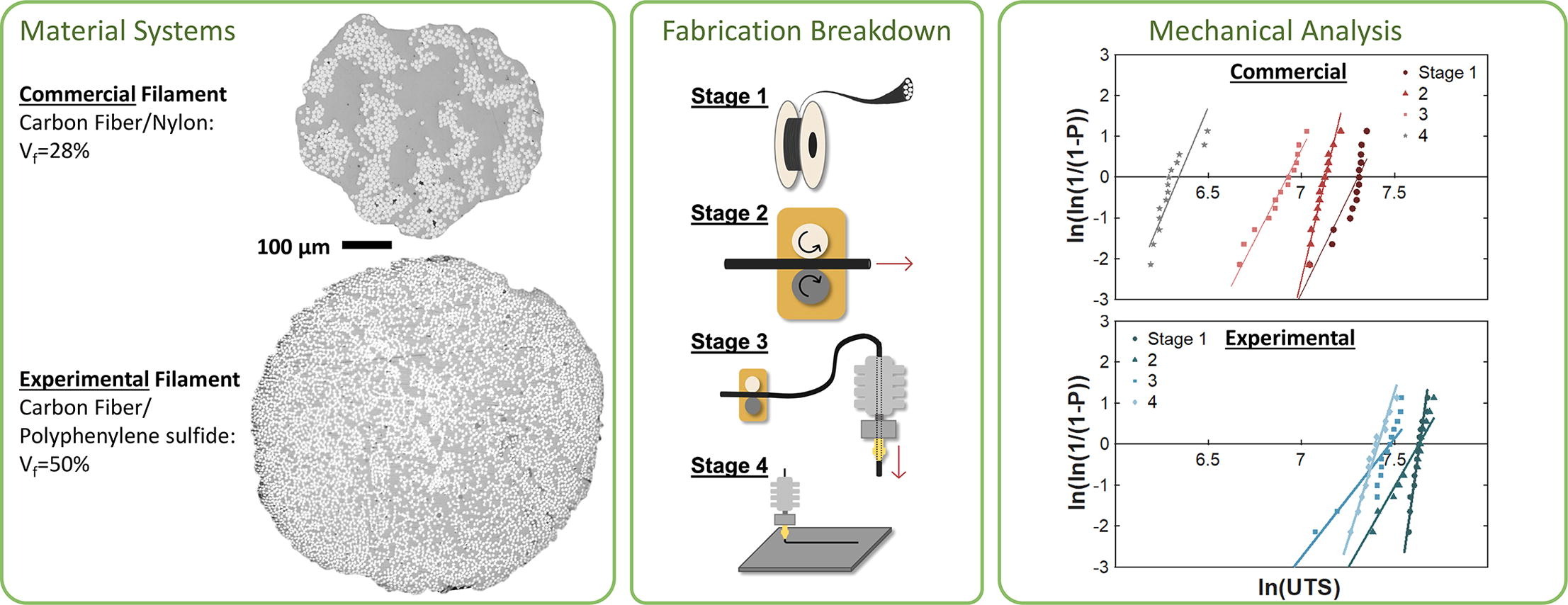

components. We seek to improve the quality and printability of novel high fiber volume fraction filaments, reinforced with both stiff and compliant continuous fibers. Although fused deposition modeling (FDM, commonly known as 3D printing) of continuous fiber composites can offer uniquely tailored structures, there is limited understanding on composite behavior and its dependence on the printing process mechanics. As such, filament strengths are evaluated at specific stages of printing under uniaxial tension and Weibull statistics are applied to characterize the strength distribution. To be implanted in industry, such systems must meet the rigorous standards for reliable and predictable manufacturability. Particularly when using stiff fibers, we intend to explore and overcome associated challenges of printing to produce net-shape components with high strength, reliability, and throughput.

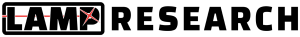

Four quadrant view of brightfield and dark field optical images showing the distribution of compliant fibers within a lab produced filament for 3D printing.

Additionally, we aim to develop a new class of composite filaments inspired by the biological structural materials of dermal armors, particularly fish scales, that enable 3D printing of advanced engineering structures with superior durability. Such filaments will consist of compliant fibers with extremely high toughness imbedded in a comparatively stiff outer matrix. It is hypothesized that through careful selection and treatment of both fiber and matrix components, successful chemical bonding between the fiber and matrix interface will exhibit decreased voids and increased final part strength. The volume fraction and size distribution of additives are expected to result in a gradient of stiffness, allowing for optimization of toughness and puncture resistance of the subsequent structures. This novel filament could provide a spectrum of mechanical properties (stiffness, strength, and toughness) that can be customized to fulfill the objectives of the printed part.

Finally, with local collaborators here in the Puget Sound, we are investigating applications for polymer-based composites within marine environments. Generally, marine composites are manufactured with traditional composite tooling and layup, and there is a poor understanding of additively produced composites material and its durability, all of which limits its practical usability. To that end, marine degradation studies are also performed in-house on polymer

parts produced via 3D printing.

Workflow of stiff fiber reinforced filaments, from left to right: cross-sections of currently utilized filaments, the separate stages of the printing process at which we measure filament properties, and a Weibull plot demonstrating differences in reliability and strength between fiber filaments.

Select Publications

M. Parker, S. Norimatsu, R. Matsuzaki, D. Arola, A Novel Filament Design for Improving Fused Filament Fabrication of Continuous Fiber Composites, Journal of Materials Research and Technology 37 (2025). https://doi.org/10.1016/j.jmrt.2025.05.251.

X. Wang, C. Travis, M. T. Sorna, D. Arola, Durability of ULTEM 9085 in marine environments: a consideration in fused filament fabrication of structural components, Polymers 16 (2024). https://doi.org/10.3390/polym16030350.

C. Marquis, R. Song, S. Waddell, A. Luong, D. Arola, Additive manufacturing with continuous ultra-high molecular weight polyethylene yarn, Materials & Design 235 (2023). https://doi.org/10.1016/j.matdes.2023.112411.

M. Parker, N. Ezeokeke, R. Matsuzaki, D. Arola, Strength and its variability in 3D printing of polymer composites with continuous fibers, Materials & Design 225 (2023). https://doi.org/10.1016/j.matdes.2022.111505.

M. Parker, A. Inthavong, E. Law, S. Waddell, N. Ezeokeke, R. Matsuzaki, D. Arola, 3D printing of continuous carbon fiber reinforced polyphenylene sulfide: exploring printability and importance of fiber volume fraction, Additive Manufacturing 54 (2022). https://doi.org/10.1016/j.addma.2022.102763.

S. Waddell, E. Law, A. Inthavong, M. Parker, D. Arola, Optimization and characterization of printing parameters on a novel continuous carbon fiber composite material for 3D printing, URMSE 1 (2020). https://doi.org/10.6069/ZDQW-PW89.