Mechanical Characterization

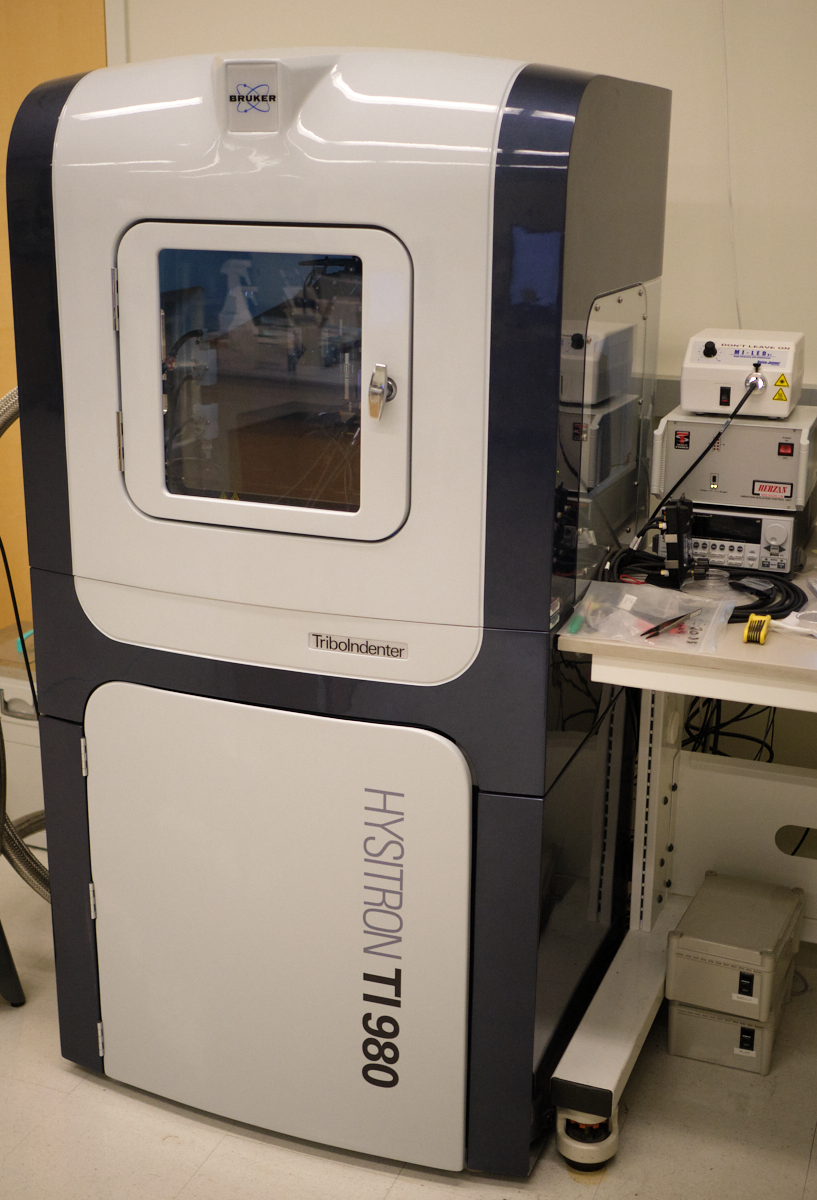

- Nanoindentation

- Provides high-resolution (~1 µm) measurements of hardness and elastic modulus.

- RR Moore

- Fully reversed cyclic bending fatigue testing.

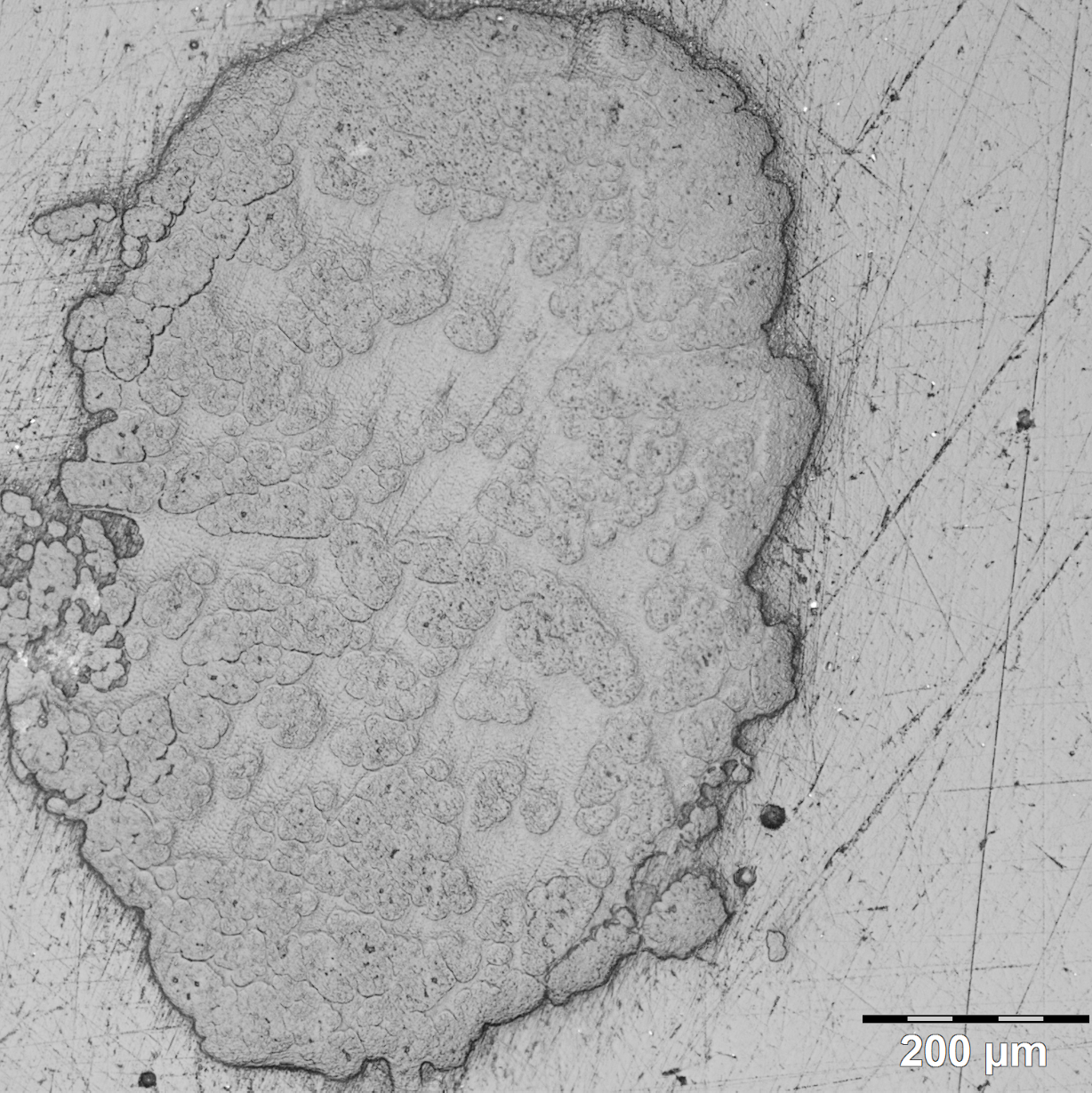

- Indentation Fracture Resistance

- Allows for the quantitative estimation of a material’s damage tolerance.

- Contact Fatigue

- Simulates repeated low-impact force, used for characterizing dental tissues, polymers, and ceramics.

- Tension & Compression Testing

- Conventional load frame testing for monotonic stress and strain measurements.

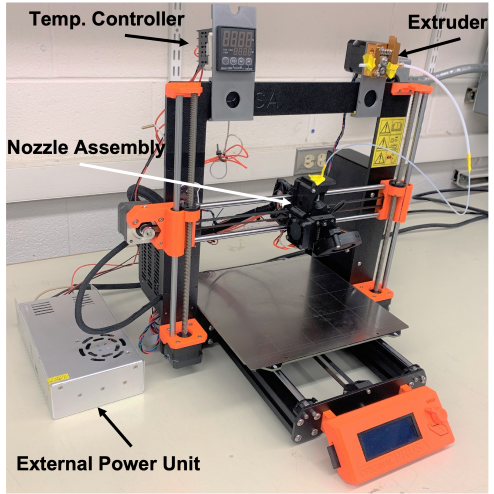

- Single-filament Tension

- Using custom-built load frame grips, we test the tensile strength of individual composite filaments used in 3D printing.

- Nano-Dynamic Mechanical Analysis (nano-DMA)

- High-resolution measurement of the viscoelastic response for softer materials, e.g. dentin, polymers.

- Puncture testing

- Testing protective capabilities of layered composites.

Structure and Composition

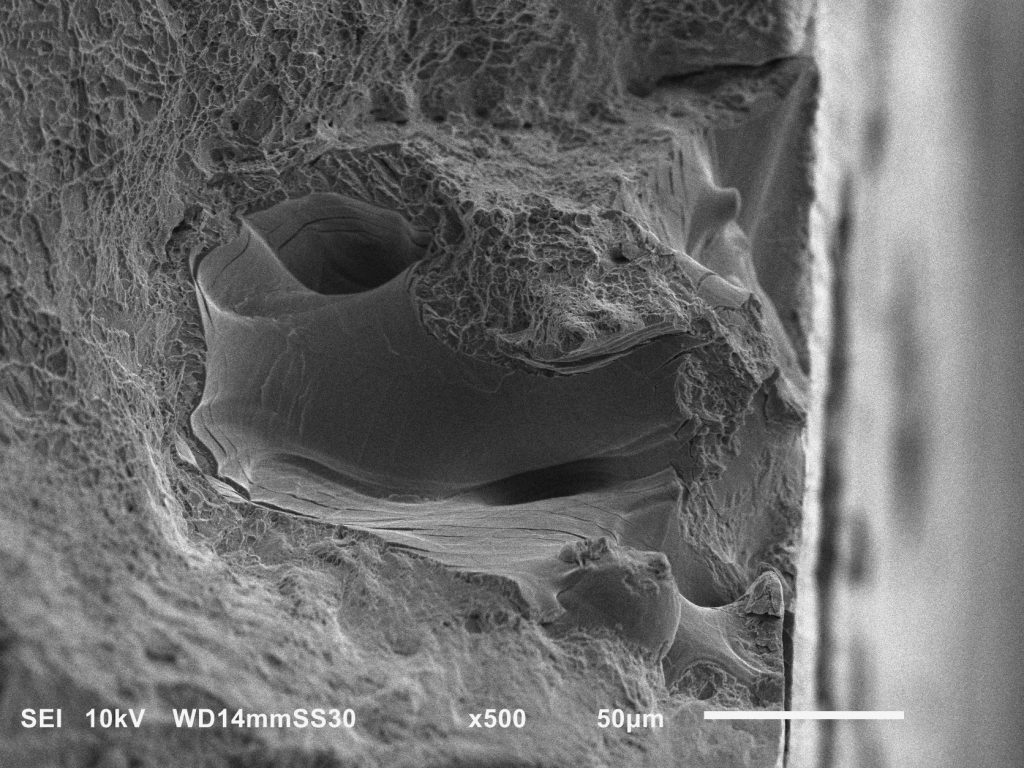

- Scanning Electron Microscopy (SEM)

- Used for high resolution imaging of prepared and fractured surfaces.

- Energy Dispersive Spectroscopy (EDS)

- Provides compositional information at the sub-micron scale, via SEM.

- Fractography

- Determining types and origins of failure. Metallographic preparation of surface for both SEM and Optical fractography.

- Micro-Computed Tomography (µCT)

- On-site systems are used for measuring porosity in titanium parts, while synchrotron sources reveal enamel structure in 3D.

- Fourier-Transformed Infrared Spectroscopy (FTIR) & Raman Spectroscopy

- Using an incident laser and measuring the light that passes through or is scattered by a sample, certain characteristics and bonds of a material can be quantified.

- Differential Scanning Calorimetry (DSC)

- Provides chemical and structural (i.e. crystallinity) of polymers and polymer composites.

Additive Manufacturing

Titanium

Industrial powder bed fusion, both electron and laser systems.

Composite 3D Printing

Modified desktop system for printing continuous fiber reinforced filaments.

Composite Filament Production

Advanced techniques for achieving carbon fiber loading of >50 vol.%