Projects > Titanium Additive Manufacturing

Lorem ipsum dolor sit amet, at mei dolore tritani repudiandae. In his nemore temporibus consequuntur, vim ad prima vivendum consetetur. Viderer feugiat at pro, mea aperiam

Improving Consistency and Efficiency Across Builds

The aerospace industry, a staple of the economy in the Pacific Northwest, is beginning to capitalize on the versatility of additive manufacturing to produce parts that might otherwise be impossible or prohibitively difficult to produce. The industry and regulators enforce the strictest tolerances for consistency and performance, regardless of the production method. Our group collaborates with several prominent aerospace companies nationwide as well as metal additive manufacturing system producers to better understand the variables that significantly impact the porosity, fatigue life, and mechanical performance of printed parts. Only once those parameters are understood can they be optimized to produce ever more efficient parts.

One of the more significant parameters is related to how many times the feedstock powder has been reused. Due to the nature of the selective melting process, the entire build space is filled with titanium powder, but only those voxels that constitute the part are melted and solidified into the final shape. The remaining powder is separated from the part and can then be reused for future prints. However, the morphology and composition of the powder particles, even those not melted during printing, is altered, and over time accumulations can degrade the final parts. Monitoring these changes and how the powder feedstock may be “restored” to a more virgin state is one focus of our research.

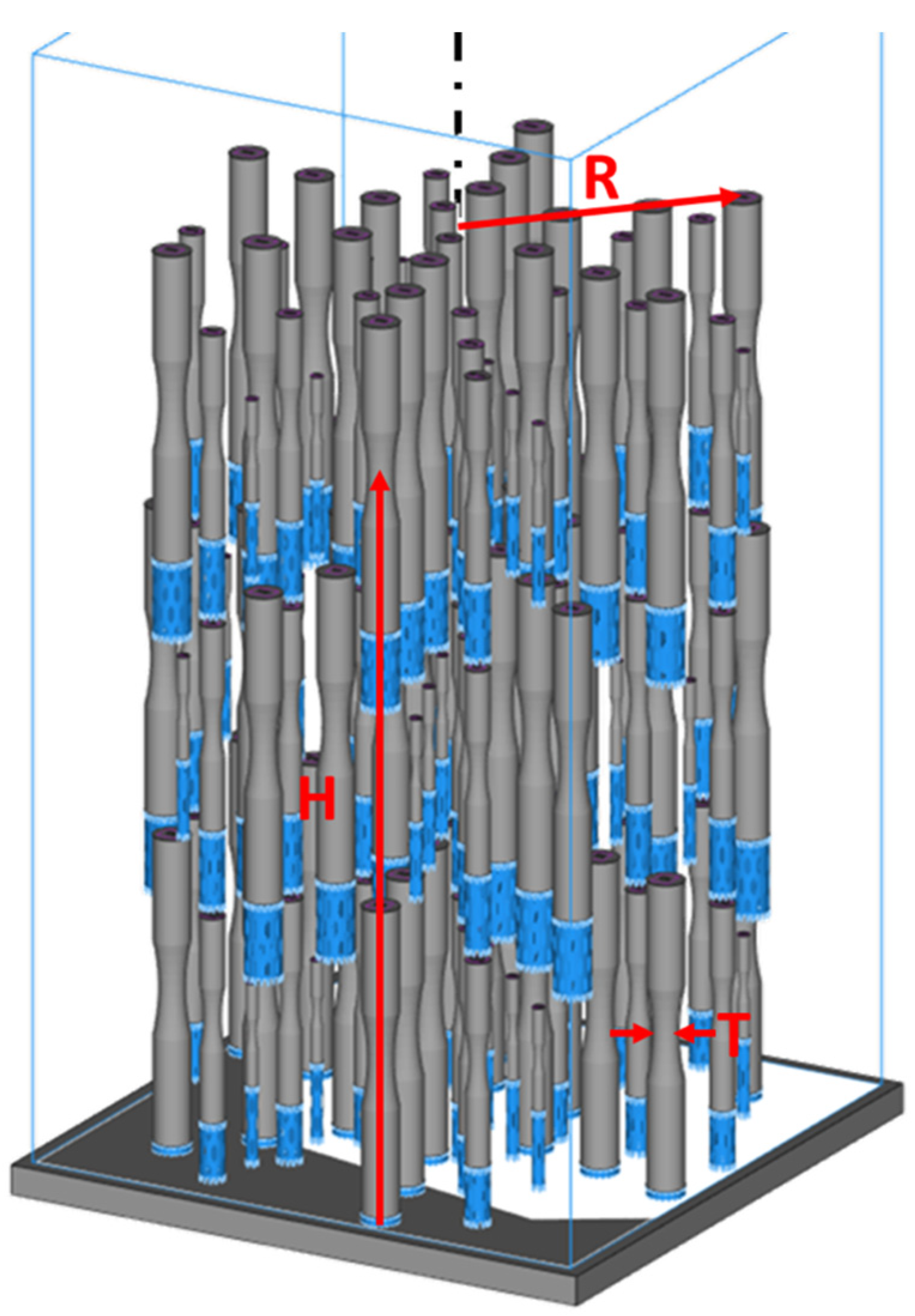

Render of the build file for a design of experiments for titanium fatigue test coupons. Three parameters are indicated, the gage thickness T of a coupon, and the height H and radial distance R from the center of the base plate. From https://doi.org/10.3390/ma15165617

The printed part may not have a completely solidified microstructure, and requires additional heat and pressure treatments (such as hot isostatic pressing, HIP) to densify the structure. We use micro computed tomography to monitor pores, along with fractographic analysis of tensile and fatigue coupons to identify where pores are likely to happen and how much of a problem they may be. Ti-6Al-4V (6 wt.% aluminum, 4 wt.% vanadium) is an alpha-beta alloy, meaning that the final microstructure is a complex mixture of both alpha and beta phases. The rapid melting and solidification cycles that the printed material experiences during printing, followed by the heat treatment for densification, only complicate this further. As with any other alloy, the microstructure is one of the primary controlling factors of the properties of the final part. For these reasons, we also perform metallographic analysis of the alpha-lathes and prior beta grains and how they change in response to the print parameters (e.g. powder reuse, location in the build chamber) and post-print treatments to ensure the optimal final part is produced.