System selection

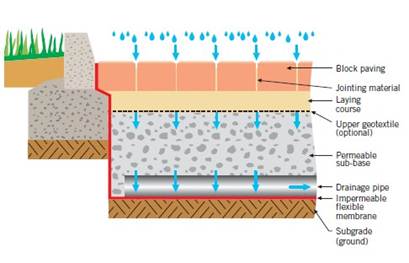

There are three different systems which can be selected for particular site conditions. These systems were initially identified by Interpave (UK) and their designations have now been adopted by British Standards, The SUDS Manual (CIRIA 2007) and elsewhere. There is no difference between the surface appearance of the different systems but each has unique characteristics making suitable.

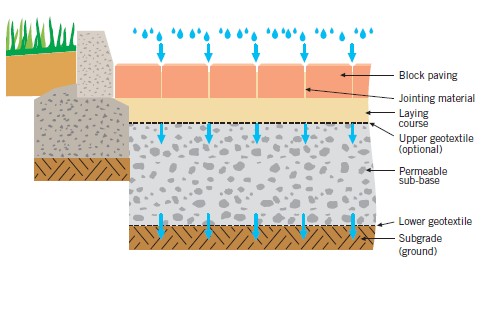

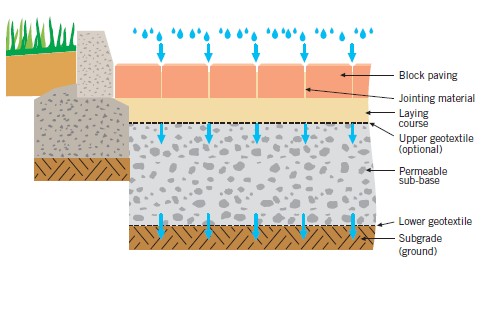

System A – Full Infiltration

Suitable for existing subgrade (ground) with good permeability, System A allows all the water falling onto the pavement to infiltrate down through the constructed layers below and eventually into the subgrade (ground). Some retention of the water will occur temporarily in the permeable sub-base layer allowing for initial storage before it eventually passes through. No water is discharged into conventional drainage systems, completely eliminating the need for pipes and gulleys, and making it a particularly economic solution.

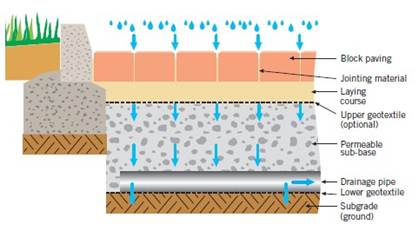

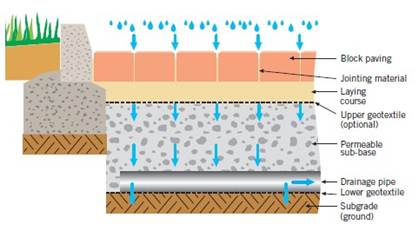

System B – Partial Infiltration

Used where the existing subgrade (ground) may not be capable of absorbing all the water. A fixed amount of water is allowed to infiltrate – which, in practice, often represents a large percentage of the rainfall. Outlet pipes are connected to the permeable sub-base and allow the excess water to be drained to other drainage devices, such as swales, ponds, watercourses or sewers. This is one way of achieving the requirement for reducing the run off volume and runoff rate of water and will most likely remove the need for any long term storage.

System C – No Infiltration

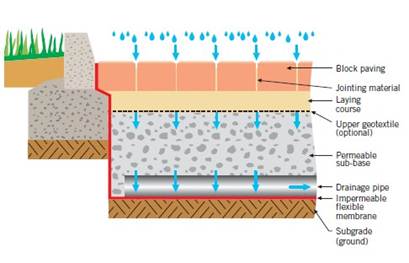

Where the existing subgrade (ground) permeability is poor or contains pollutants, System C allows for the complete capture of the water. It uses an impermeable, flexible membrane placed on top of the subgrade (ground) level and up the sides of the permeable sub-base to effectively form a storage tank. Outlet pipes are constructed through the impermeable membrane to transmit the water to other drainage devices, such as swales, ponds, watercourses or sewers. Importantly, the outlet pipes are designed to restrict flow so that water is temporarily stored within the pavement and discharge slowed. System C is particularly suitable for contaminated sites, as it prevents pollutants from being washed further down into the subgrade (ground) where they could reach groundwater.

Siting requirement for permeable paving (Seattle)

- Area of installation –the area of installation must be at least 2,000 square feet or one block frontage, whichever is less.

- Longitudinal Slope – the longitudinal slope must not exceed 5% .

- Existing Trees and Tree Canopy – In areas with mature trees the root zone must be considered. Retention of tree roots necessary to support the health and future growth of the tree may dictate the limits of the paved area as well as the drainage capacity for permeable paving. Additionally, areas shaded by trees may be limited to a specific type of permeable paving or may be considered unsuitable altogether.

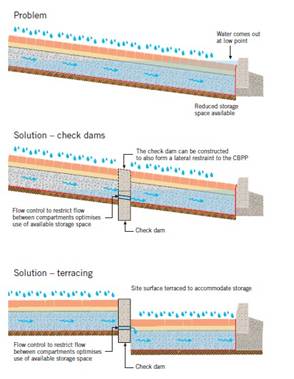

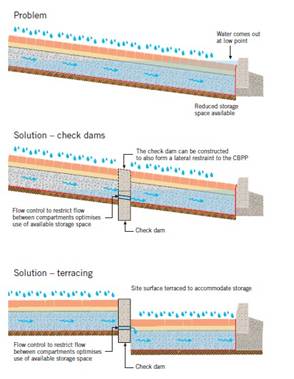

When constructing permeable pavement on sloping sites, care is needed to ensure that the water in the permeable sub-base does not simply run to and collect or overflow at the lowest point, or the available storage will be reduced. There are four potential solutions:

• Install check dams within the permeable sub-base with flow controls to ensure the water does not flow to the lowest level and discharge from the surface.

• Terrace the site to give flat areas of permeable paving that have separated permeable sub-base storage areas.

• Use high capacity geocellular storage at the bottom of the slope to increase storage capacity.

• Increase the permeable sub-base thickness to allow for reduced storage capacity at the top of the slope.

Maintenance should always be planned for with permeable pavements as the void spaces between the pavers and/or the pores in the paving can become blocked. Jet-washing, commercial street sweeping or vacuuming may be required.

There is some risk of groundwater contamination when using porous paving. Pollutants such as nitrates and chlorides may not be filtered out by the pavement or the soil, and as a result might contaminate the groundwater. Therefore, porous pavement should not be used near groundwater drinking supplies. However, current knowledge of these effects is not conclusive. Some initial studies in Rockville, MD and Prince William, VA suggest that porous pavement may have high removal efficiencies for sediment, phosphorus, nitrogen, zinc, lead, and chemical oxygen demand (EPA, 1999). |