Sweet Water Organics

Milwaukee, Wisconsin

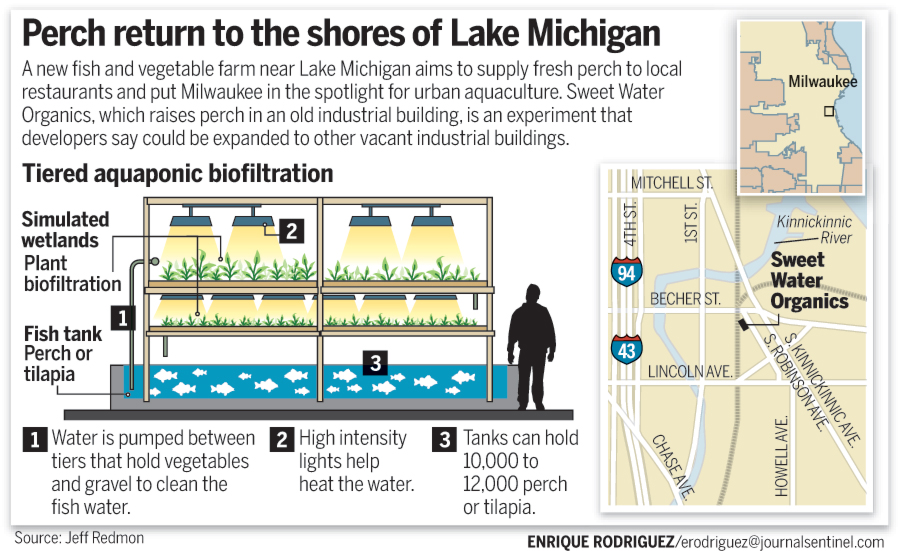

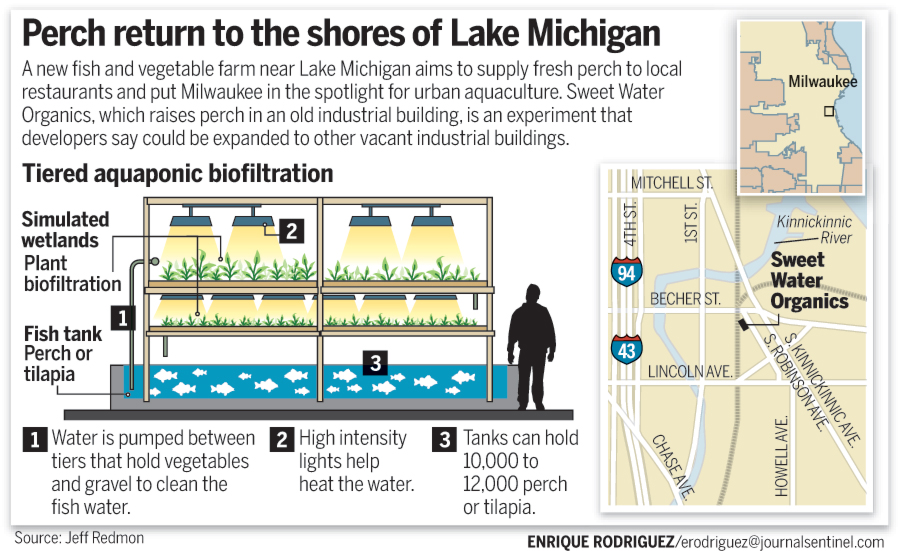

Scope of operation

Focus on perch cultivation & produce for local market

System mimics wetland: gravel & variety of plants filter water; plants are nourished through fish waste in water supply

Facilities

Empty industrial / manufacturing building

Products

Tilapia, perch (local native fish / popular for fish fries)

Vegetables: lettuce, basil, tomatoes, chile peppers, watercress

(had raised 3,000 perch / 45,000 tilapia at time of article; intend to focus on perch)

Vegetables are more profitable than fish – but having both in system increases efficiency

Inputs

Compost (from local restaurants that are supplied by Sweet Water)

Fish food

Electricity (light, pumps)

Waste

Solid waste from fish (must be removed from system periodically)

Additional benefits

Occupy unused urban space / infrastructure (abandoned manufacturing sites)

Reduce farm-to-table distance

Reduce water usage & soil disturbance

Bring native fish back to local diets after perch fishery collapse

Provide contaminant-free fish & produce in polluted areas

Reduce food production footprint

Potentials for increased efficiency

Include vermiculture to convert fish waste to plant nutrients

Explore alternative energy sources (wind, solar)

Reduce energy usage (daylighting plants, gravity-based water circulation systems)

Expand operations to include aquaculture system training & installation

Add rooftop farming operations to decrease urban impervious surfaces

Natural Green Farm

Racine, Wisconsin

Scope of operation

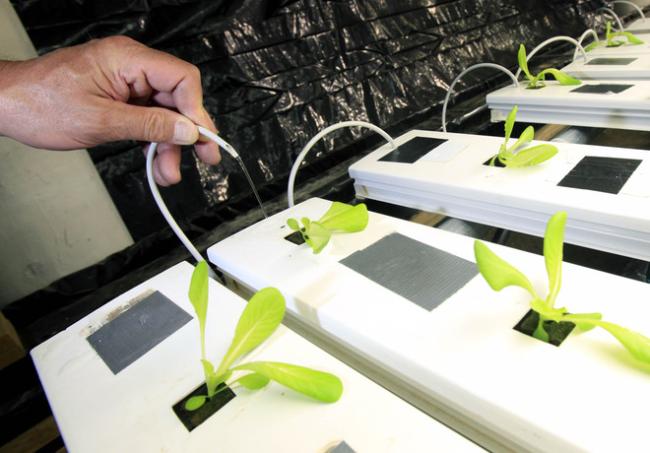

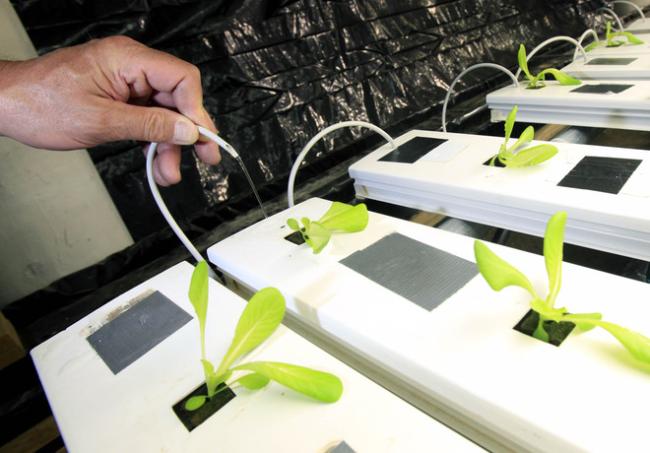

Focus on plant production / fish is additional benefit

Growing system made up of fish tanks topped by hydroponic growing trays; feeder tubes drip fish water into hydroponic system/ plant wastewater drips into fish tanks

Facilities

10,000SF of 200,000SF factory building

Products

Lettuce (currently 7,000 heads)

Fish (24,000 tilapia / varying stages of development)

Goal: 4 million heads lettuce, 1 million pounds fish, rooftop tomato greenhouse

Inputs

Electricity: grow lights ($0.40 / head of lettuce)

Electricity: water pumps

Fish food

Savings

Water (<10% of traditional agriculture usage)

Space (vertical stacking)

Pesticides & fertilizer (none used)

Waste

Solid waste from fish (must be removed from system periodically)

Additional benefits

Occupy unused urban space / infrastructure (abandoned manufacturing sites)

Reduce farm-to-table distance

Reduce water usage & soil disturbance

Reduce overfishing

Provide contaminant-free fish & produce in polluted areas

Reduce food production footprint

Potentials for increased efficiency

Include vermiculture to convert fish waste to plant nutrients

Include composting to augment plant nutrients

Explore alternative energy sources (wind, solar)

Reduce energy usage (daylighting plants, gravity-based water circulation systems)

|