|

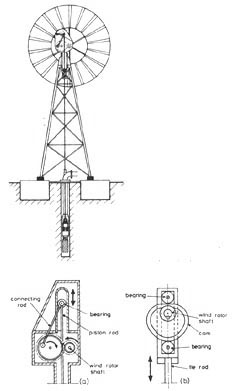

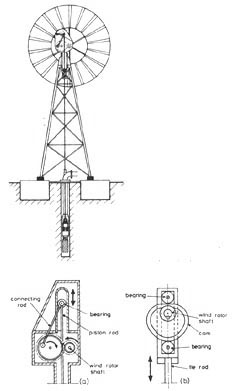

Figure 1. Slow wind turbine driving a

piston pump. Taken from Le Gourieres, Desire, Wind power

plants: Theory and design, Oxford, England, Pergamon Press,

1982, p.152.

|

Wind turbine systems are most promising as sources of centralized

electric power. In the hills of Southern California, for example,

thousands of turbines are installed in wind power plants,

known as "wind farms." Remote wind power systems

often incorporate additional generating systems such as diesel

generators and solar arrays. These "hybrid" systems

provide an improved reliability of power supply and operational

flexibility. When the power from the wind turbine is not sufficient

to operate the load, the alternate power source comes on-line.

The alternate source is used far less frequently in a hybrid

system than if the wind system were not present.

A widely used application of wind turbines is for producing

electric power on-site at homes, farms, and businesses, which

are already served by a utility grid. Because the average

wind turbine generates electricity only 25 to 30 percent of

the time, it may be important in areas where winds are seasonal

or where storage systems are not cost-effective to be connected

to the electric utility grid.

Wind power can also be used to pump water. It is important

to note that the use of wind power to pump water requires

the correct wind velocity and hydrogeological conditions.

Various mechanisms are used to transform the rotational motion

of the windmill into a reciprocating motion that can be utilized

by the pump (Figure 1).

|