Organic Photovoltaics

Background and Challenges

Organic photovoltaics (OPVs) represent a transformative technology with great potential for extremely high-throughput manufacturing at very low cost, and are made from non-toxic, earth-abundant materials with low energy inputs. They have the potential to serve as lightweight, flexible, conformal, and low-cost solid-state power sources. However, their performance must be improved before they can be viable for commercial applications.

Current state-of-the-art OPVs exhibit power conversion efficiency (PCE) of ~9 % in small size (20% for single cells and even higher for tandem cells by tuning material properties, such as bandgap, charge mobility, and energy levels to optimize the light absorption, charge transport, and photovoltage. Developing these optimal materials remains challenging and continuous improvements in material design and chemical synthesis are urgently needed.

Fabricating an efficient OPV module represents another challenge. Nearly 50% efficiency is lost when scaling from a champion cell to a large-area module (>100 cm2) because of improper metrology and manufacturing protocols for high volume processes and ohmic loss of the commonly used transparent indium tin oxide (ITO) electrode. The translational efficiency is even worse with flexible cells as the resistance of ITO-coated plastic substrate increases dramatically (>60W/sq). Moreover, ITO is unsuitable for flexible OPVs because it is brittle. Therefore, the development of a new flexible transparent electrode with high transparency, low sheet resistance, and mechanical robustness is extremely critical for making OPV a viable product.

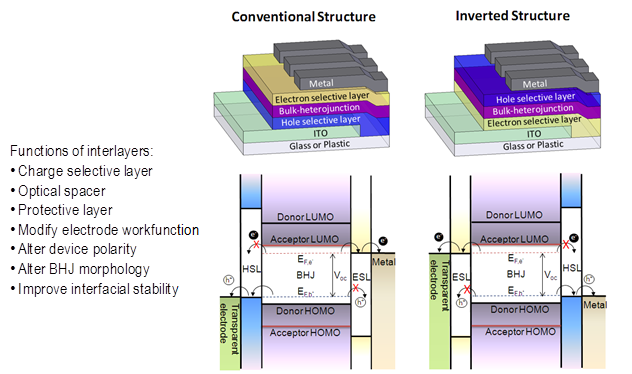

In addition to developing new light-harvesting materials and transparent electrodes, optimizing interfacial properties and developing new device architecture will be needed. A charge selective buffer layer with tailored electronic and electrical properties inserted between the electrodes and the bulk heterojunction (BHJ) layer can significantly improve the charge collection efficiency by reducing the contact resistance and interfacial recombination loss. These optimizations could lead to a significant improvement in all the critical parameters for OPV. Moreover, the development of new inverted device architecture for better stability against degradation and compatibility with the roll-to-roll manufacturing process for flexible OPV cells is also critical for commercialization.

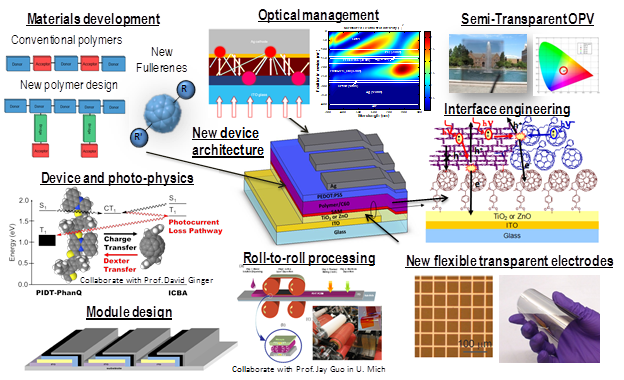

The overall objective of our OPV research is to use an integrated approach combining material, optical, electrode, and device engineering to demonstrate the feasibility of using solution processing to fabricate high-performance flexible organic photovoltaic device and module.

An Integrated Approach for Enhancing Polymer Solar Cells Performance through Material, Optical, Interfacial, and Device Engineering

Here are some highlighted topics in our program:

Optimize both donor and acceptor materials to improve the performance and morphological stability of OPV with high power conversion efficiency (PCE)> 10% and develop new ink formulations based on environmentally friendly solvents for large-scale coating process.

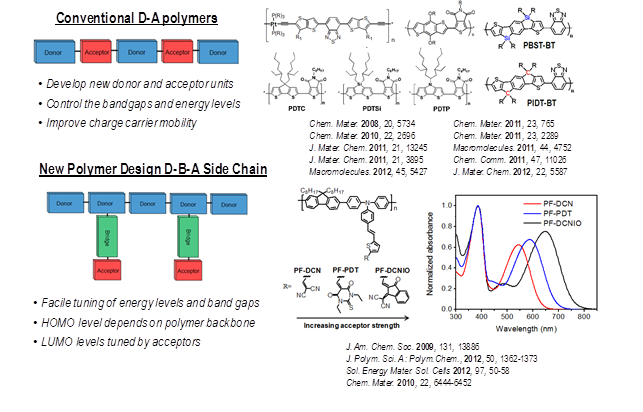

The development of better p-type and n-type semiconductors with appropriate electrical, optical (HOMO/LUMO, bandgap, charge mobility) and morphological properties is important to improve the performance of OPV. To optimize the material properties, conjugated polymers with alternating electron-rich and electron-deficient units along their backbone have been extensively studied. This is because their absorption spectra and bandgap can be readily tuned by controlling the intramolecular charge transfer (ICT) from the donors to the acceptors. Using this approach, several classes of narrow bandgap donor-acceptor type (D-A) conjugated polymers developed in our laboratory shown very promising performance with a PCE over 7-8%

Development of new electron acceptor materials is equally important for high performance and stable OPVs. Fullerene derivatives are the most widely used electron acceptors in BHJ cells, and the current challenge is to develop fullerenes that give better morphological stability. Greater stability will improve the device longevity. Also, by adding tailored LUMO levels, the open circuit voltage of OPV can be increased. We target to integrate these high performance active materials with an interface engineering-enhanced device structure to further improve the performance of our OPV to over 10% PCE.

Develop novel interfacial materials to reduce interfacial charge recombination loss and enhance the interfacial stability and charge selectivity at the charge-collecting electrodes.

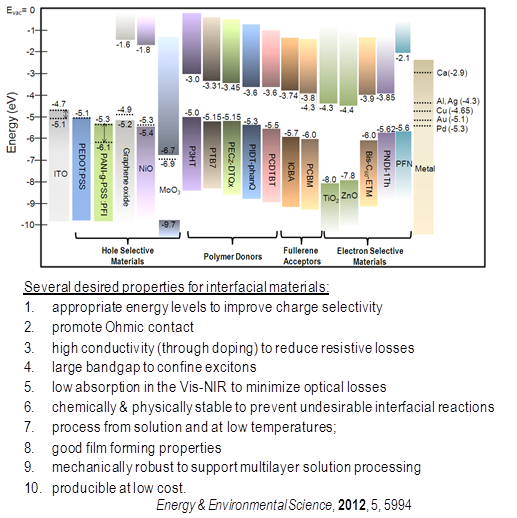

The introduction of proper interfacial materials to optimize the electronic and electrical properties between the interfaces of light-harvesting active layer and the charge-collecting electrode has become an important criterion to improve the performance of polymer solar cells. The electronic processes at these interfaces play a critical role in determining the efficiency for photon-to-electricity conversion. An ideal interface requires the formation of Ohmic contact with minimum resistance and high charge selectivity to prevent charge carriers from reaching the opposite electrodes. For long-term stability of polymer solar cells, interfaces with matched surface energy are required to prevent interfacial dewetting and delamination. Our group has studied several classes of interfacial materials including inorganic metal oxides, crosslinkable charge-transporting materials, conjugated polymer electrolytes, self-assembled functional molecules, and graphene-based materials. These interfacial materials are integrated with new low bandgap polymers and fullerene derivatives as active materials to improve the performance of OPV device in different architectures.

Functions of interfacial materials and their applications in different device architectures

Design criteria for interfacial materials

Develop high performance semi-transparent polymer solar cells for power generating window applications.

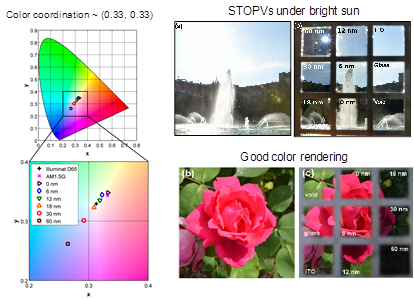

Realization of semitransparent organic photovoltaic cells (STOPV) is an important step toward the solution to the problems encountered in new applications such as power-generating tinted thin films coated on the screens of the laptops, automobile windshields, house windows, foldable curtains, and other architectural and fashion applications. Besides semi-transparency, window integrated applications require a reasonable transparency perception and good color rendering properties in order to be suitable for realistic scene illumination. However, the current performance of STOPV is much lower (Power conversion efficiency (PCE) <3% and average visible transmittance (AVT) <15%) than their opaque counterpart and significant advancement for STOPV must be achieved before they can be considered as viable commercial products.

Our research focuses on improving the performance of STOPVs by 1) developing optical models to calculate the photon absorption vs transmission in semitransparent OPV device and build up performance relationship between maximum achievable power conversion efficiency and visible light transmittance; 2) developing new low bandgap materials with high absorption coefficient for near infrared light to enhance light harvesting in NIR region while maintaining good transmittance in visible region; 3) employing integrated approach combining interface, materials and electrode engineering to achieve STOPV with high PCE and high AVT and 4) optimizing the color rendering index(CRI) of STOPV to ~100. CRI of typical blackbody radiation such as incandescent light bulb is defined to be 100. A STOPV with CRI close to 100 shows only reduced transmittance of an image without any color distortion.

STOPVs with high PCE and AVT and good CRI close to 100 for power generating window applications