During roadway construction, transportation agencies frequently unearth industrial soil contamination that threatens both public health and the environment. Management of such compounds to meet environmental regulations can cause construction delays and increase costs.

Soils co-contaminated with high-molecular-weight polycyclic aromatic hydrocarbons (HMW-PAHs) and metals are commonly encountered in Illinois, and they are resistant to conventional remediation technologies. This problem is exacerbated in the fine-grained soils common to Illinois, where low-permeability and immense sorption capacity require increased treatment complexity, cost, and duration.

Contaminated sites usually have limited space and require rapid in situ treatments, but conventional soil remediation requires about one to three years. Consequently, for expediency, transportation agencies typically remove contaminants by excavating them and disposing of them off-site. However, because this procedure is expensive, a comparatively expeditious and affordable treatment alternative is needed to address the ever-increasing cost of hazardous waste disposal.

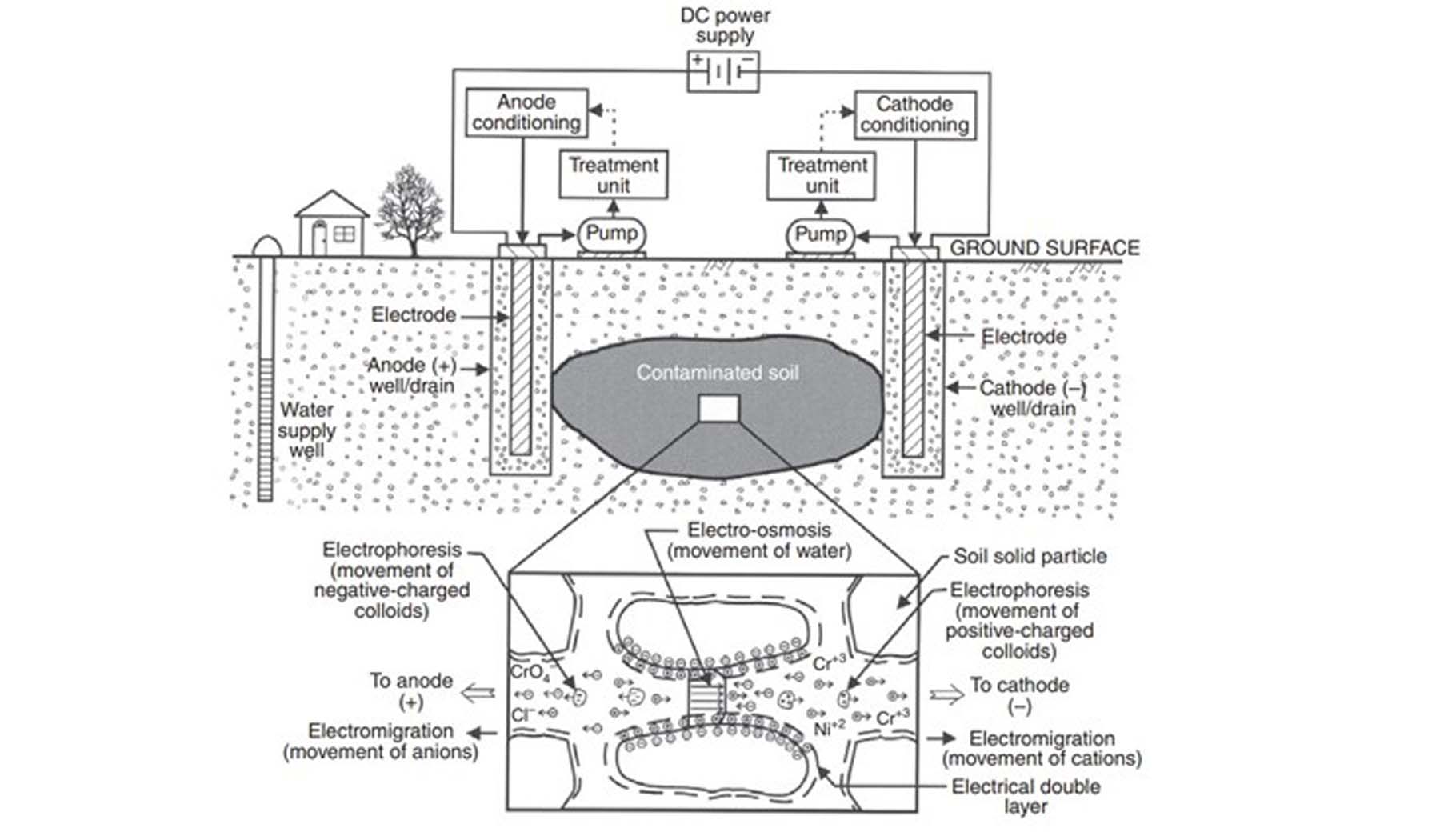

For this study, the researchers sought to develop an accelerated in situ remediation approach adaptable for use at any construction site to cost-effectively remove HMW-PAHs and metals from clayey soil. They hypothesized that an in situ electrochemical treatment that augments electrokinetics with hydrogen peroxide (H2O2) could remove both HMW-PAHs and metals in less than a month.

The researchers designed and fabricated bench-scale reactors to resemble field-scale, in situ electrokinetic systems to assess the electrochemical treatment of contaminated clayey soils. Pyrene, chromium, and manganese were used as model contaminants, spiked into kaolinite as a model clay. Electrokinetics were applied with a low-intensity electrical field distributed by graphite rods. Electrolytic H2O2 systems were leveraged to distribute electrical current and facilitate contaminant removal. An average contaminant removal rate of 100 percent was achieved for pyrene, 42.3 percent for manganese, and 4.5 percent for chromium.

Successful development of this bench-scale treatment approach will help guide transportation agencies in field-scale implementation. The results from this work showed that electrochemical systems that leverage eco-friendly oxidant addition can replace excavation and disposal as a means of addressing clayey soils co-contaminated with HMW-PAHs and metals.

Authors:

Austin Pelletier

Amanda Hohner

Idil Deniz Akin

Indranil Chowdhury

Richard Watts

Xianming Shi

WSU Department of Civil and Environmental Engineering

Brendan Dutmer

Highland Community College

James Mueller

Provectus Environmental Products, Inc.

Illinois Center for Transportation

Sponsors:

Illinois Department of Transportation

Federal Highway Administration