Multi-material and Multi-tool Additive Manufacturing of Functional Devices

Ph.D. Student: Vinh Nguyen

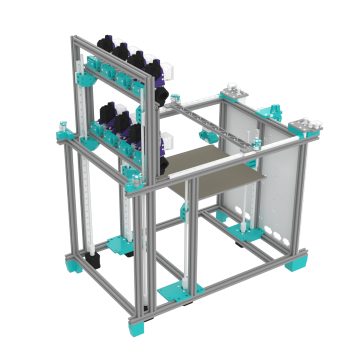

Digital fabrication and additive manufacturing (AM) tools have become more broadly accessible, but research still needs to be conducted on how to translate fabrication workflows and materials to functional prototypes and devices that go beyond aesthetics. We are developing new fabrication tools, workflows, and materials that will enable efficient integration and packaging of multiple materials and components in a single platform for fabrication of functional devices. Our current research includes the development of a modular platform, software for toolpath control, and development of new printable functional materials for energy storage devices. This project is in collaboration with Professor Nadya Peek in HCDE.

Unfortunately, this project is not recruiting new undergraduate and master’s students at this time.

Modeling 3D Lithium-ion Batteries

Ph.D. Student: Chih-Hsuan (Doris) Hung

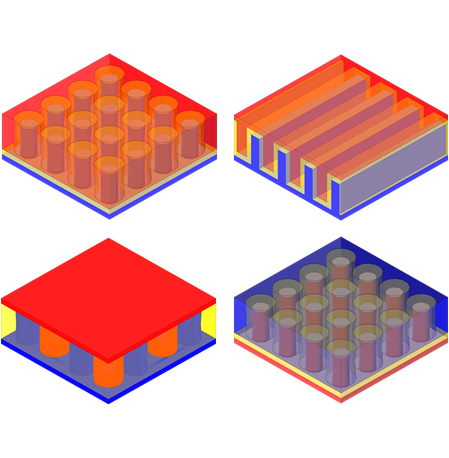

Conventional Lithium-ion batteries (LIBs) are composed of planar stacks of cathode and anode electrodes with a polymer separator sheet sandwiched in between. Three-dimensional (3D) batteries, where the anode, cathode, and separator are engineered into three-dimensional (3D) architectures, have been proposed as an alternative to planar LIBs to significantly improve energy, power, and fast charge performance. Various 3D battery designs have been proposed over the years, but their relative performance gains in different material systems are not yet well-understood. As manufacturing techniques advance, new design possibilities for new 3D batteries are introduced. Currently, we are computationally modeling existing and new 3D battery designs and have recently work in this area (click here and click here).

Unfortunately, this project is not recruiting new undergraduate and master’s students at this time.

Acoustic Focusing and Additive Manufacturing

Ph.D. Student: Emilee Armstrong

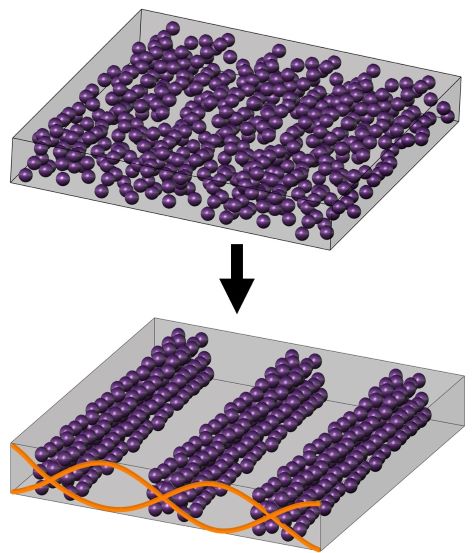

Patterned functional materials have been shown to improve material properties (electrical, mechanical, thermal, etc.) over their bulk counterparts. Acoustic focusing is a fabrication process that can rapidly drive functional materials into intricate three-dimensional (3D) patterns, but further research is needed to understand how this process can be better tuned to achieve different 3D patterns over large areas. Currently, we are investigating how to combine acoustic focusing principles with additive manufacturing to pattern Lithium-ion batteries.

Master’s students who are interested in this project will have opportunities to assist with experimental work and/or data processing. Please follow our lab’s application instructions (click here) for the Master’s student category if you are interested in joining this project.

Material and Process Design for 3D Printing Lithium-ion Batteries

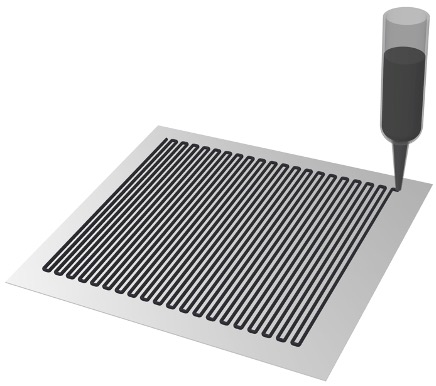

Ph.D. Student: Michelle Katz

Traditional Lithium-ion batteries are limited by a trade-off between energy and power due to their planar electrodes. 3D Lithium-ion batteries present a path to overcome this limitation, but new material formulations and manufacturing processes must be developed to enable fabrication of these structures at small size scales and over large areas. We are developing new material formulations and additive manufacturing processes to enable 3D printing of 3D lithium-ion batteries.

Unfortunately, this project is not recruiting new undergraduate and master’s students at this time.

Data-driven Alloy Development for Metal Additive Manufacturing

Ph.D. Student: Zachary Lewandowski

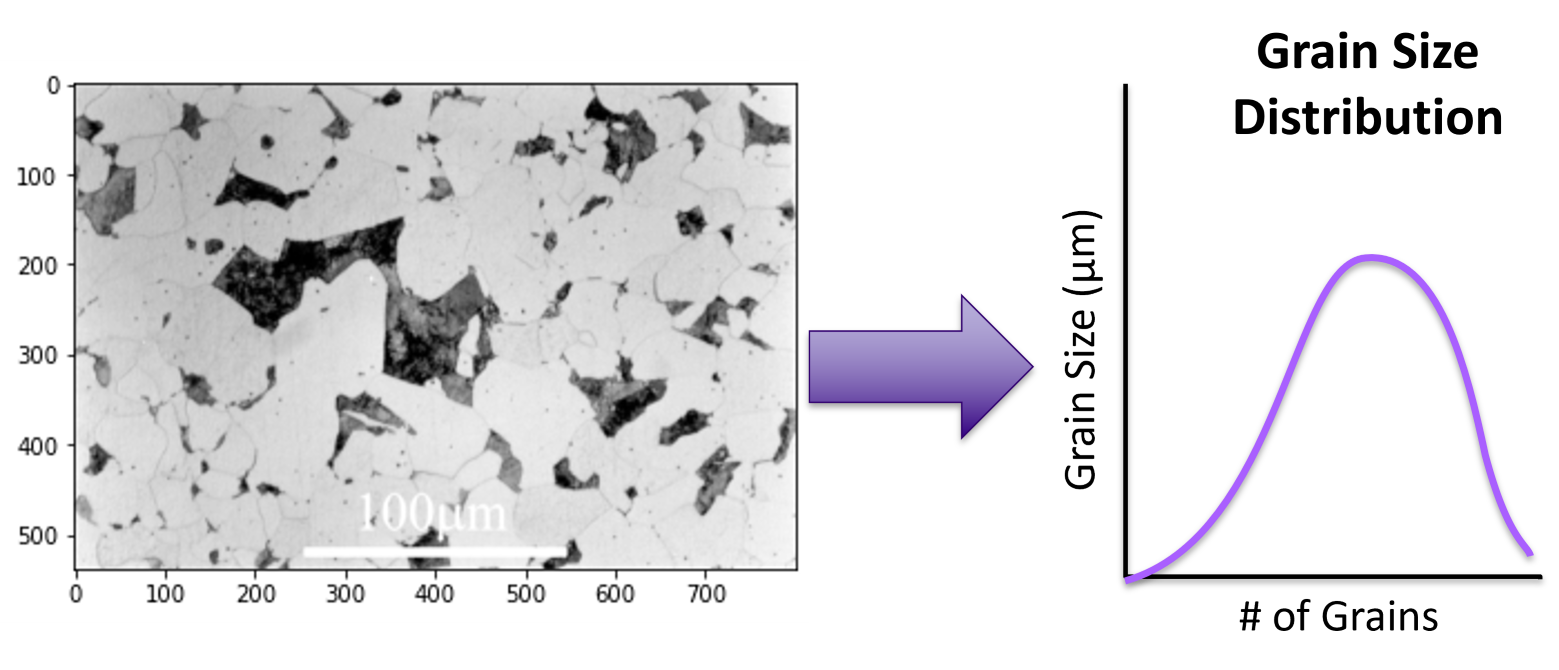

Laser Powder Bed Fusion (LPBF) is a method of manufacturing solid metal objects layer-by-layer that enables the creation of parts with geometries that would be impossible to make using more traditional manufacturing methods. The properties and microstructure of metals processed using LPBF are not completely understood, leading to difficulties for engineers designing parts for additive manufacturing. We utilize a combination of experimental materials characterization, computer vision, and data-science to identify relationships between alloy composition, process parameters, and microstructure of LPBF components. Our goal is to combine these insights with multi-scale materials simulations in order to accelerate the development of novel metal alloys that are stronger and less prone to flaws caused by the LPBF process.

Undergraduate and Masters students who work on this project will have opportunities to gain experience with either experimental work focused on materials characterization or computational work developing computer vision, database management, or artificial intelligence algorithms. If you are interested, please follow our lab’s application instructions (click here) for the category that applies to your degree level.