Bio-medical Fiber

Biomedical research has many labor intensive analysis techniques. The application which motivated this study injects a small amount of fluid into a square slide and allows crystals to grow inside the square channel. The channel length is limited to a micro-scope slide, where the square channel loops back and allows a researcher to follow the channel. Automation of the process is possible if spooled square fiber is available to house the injected fluid and the microscope inspection process may be improved so manual operation of the microscope is not necessary. This work focuses on drawing small diameter (0.2 mm) square hollow crystals for a biomedical application. The challenges in drawing square hollow fiber are summarized below:

- Complex transient natural convection may occur in the air around the preform during the drawing process and may create unacceptable variation in the fiber diameter.

- If the walls are too thin (high aspect ratio) the fiber will fracture when wound, making it unsuitable for industrial use.

- The fiber diameter must be small to minimize the volume of fluid for biomedical testing applications. The target width for this work is 0.2 mm.

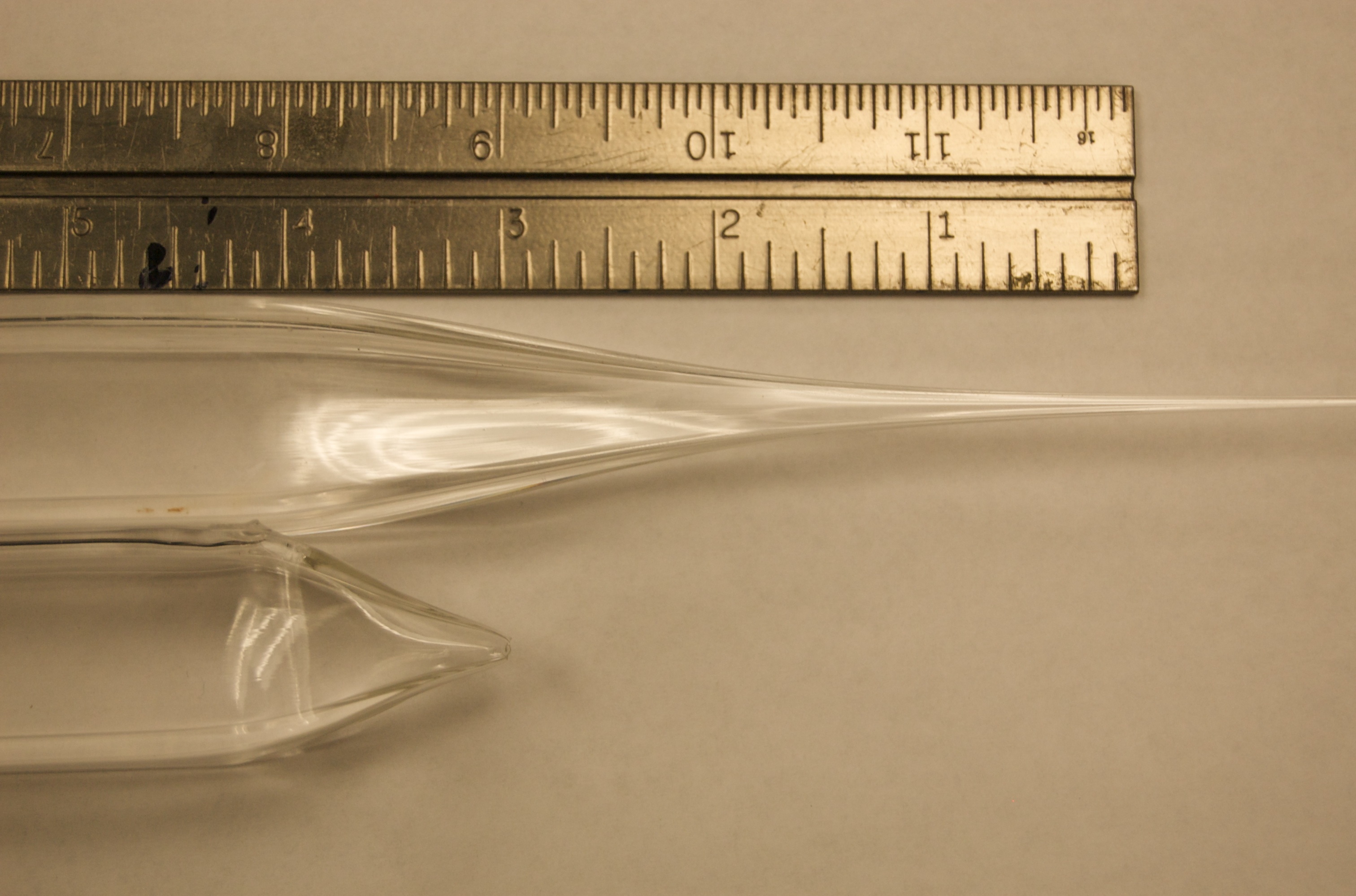

Free surface shape of the preform in the neck down region. The upper preform shows a good neck down, where the shape of the preform reduces gradually. The lower preform shows a rapid neck down that failed via wisping.

Modifications to the existing manufacturing system were necessary to overcome the challenges in drawing high aspect ratio square fiber. The modifications included design of an active cooling system for the entering preform, improved air sealing in the upper iris, and adjustment of fiber draw speeds.

Birefringence Crystal Analysis

After successful manufacturing of small width fiber, testing was conducted to determine applicability to the biomedical field. Crystals were grown in polymer fiber for the purpose of testing general crystal growth in this fiber, learning how these crystals in fibers appear in a novel birefringence imaging system, and providing a crystal in fiber specimen suitable for crystal structure analysis by x-ray crystallography. Mannitol (a diabetic sugar) and granulated white sugar (sucrose) were used for crystal material.

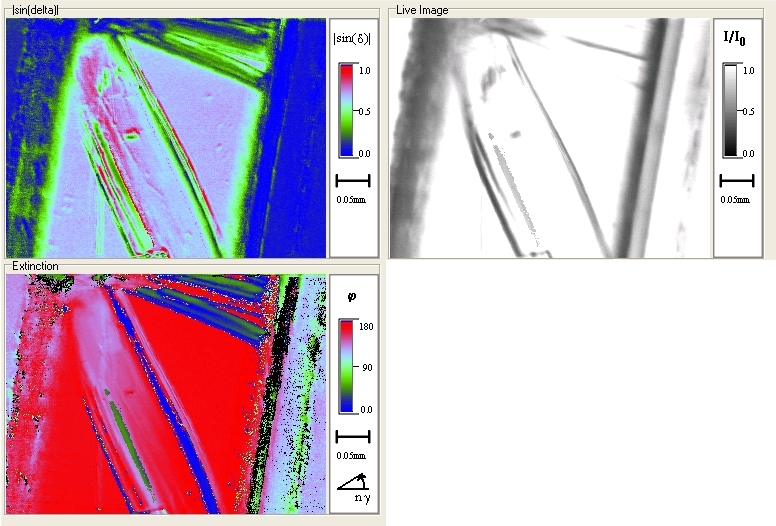

Biofringence view of a typical sugar crystal found in fibers.

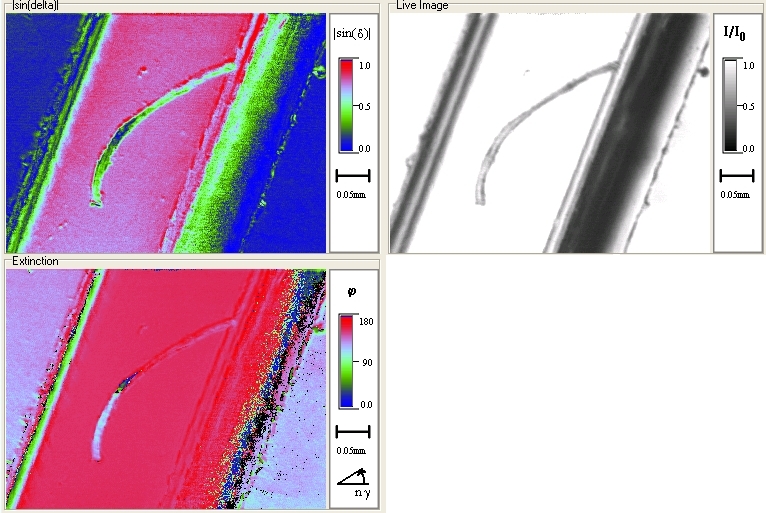

Biofringence view of the best sugar crystal grown to date.