Dendrimer-doped POF

Background

Doping a dye into an optical fiber can change the way the fiber carries an optical signal. Usually, the fiber is used to just propagate a signal across large distances for use in telecommunication. This fiber is usually made out of glass with no incorporated impurities. Doping the fiber with a dye can allow for devices that are able to amplify or otherwise change an optical signal without first converting the optical signal into an electrical signal and back. This decreases the cost of amplification devices, and allows optical fiber to stretch across hundreds of miles.

Polymer optical fiber has several advantages over glass fiber in that it can be cheaper to manufacture and cheaper to splice separate fibers together. It has the disadvantage in that it cannot carry a signal for the distances that glass fiber can. Incorporating dye into polymer optical fiber is likewise cheaper than incorporating the dye into glass fiber. Another advantage of using dye doped polymer as a non-linear optical amplifier is its susceptibility to the non-linear effects of the dye, which is greater than in glass. Practically, this means that a non-linear optical amplifier made of polymer can be much shorter than an equivalent amplifier made of glass. The ability to use shorter lengths of polymer fiber negates the disadvantage of greater signal attenuation.

Other uses for dye doped polymer optical fiber include devices such as solar pumped lasers and photo-electronic circuits.

Research here focuses on incorporating dye into polymer fiber optics. The polymer used here is polymethyl methacrylate (PMMA), a polymer commonly used in polymer fiber optics. The dye is mixed into a methyl methacrylate (MMA) monomer solution, which is a liquid. The monomer solution is then poured into a cylindrical glass mold to be polymerized in a heated water bath. What results when the glass mold is broken away is a cylindrical piece of solid PMMA with the dye dispersed within, called a preform. This preform is then mounted into cylindrical furnace and drawn into a fiber. The fiber can then be used as part of an optical device as described above.

Process

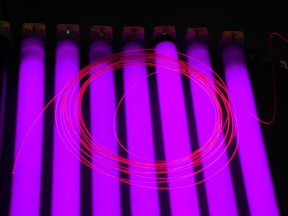

A poly methyl methacrylate (PMMA) preform was made in the laboratory. The doping agent inserted during the polymerization. The preform was then drawn into fiber in the furnace. This fiber emits red light when exposed to higher energy UV light such as this blacklight source seen below.