Photonic Bandgap POF

By incorporating axial holes in optical fiber it is possible to achieve properties that cannot be achieved by the use of solid optical fiber. These fibers are also known as photonic crystal fibers (PCFs) and the holes can be arranged for different desired properties such as maintaining polarization, nonlinear applications, single-mode fibers, and high numerical apperature (NA) fiber.

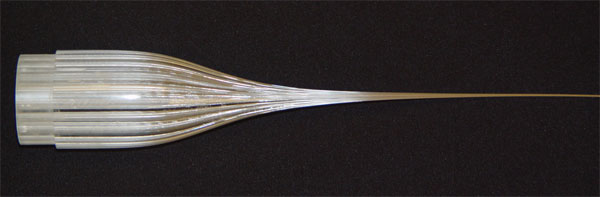

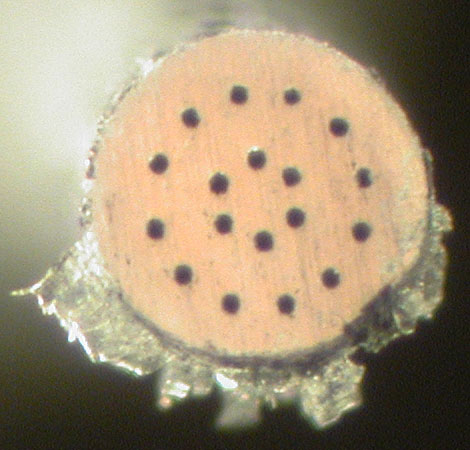

Research being conducted here at the University of Washington is focused on applying PCF technology to polymer fibers instead of glass, which is the most common type of optical fiber. Many hole structures have been designed and tested such as the preform shown below. The first picture shows the shape of a necked down preform, followed by a view of the cross section of the same preform, which has a three ring hole structure.

It is important to control the fiber drawing process in order to ensure that the holes do not collapse as the fiber diameter drops to as low as 200 microns. The fiber must also maintain uniformity of the aspect ratio between the holes and the outer diameter. Analyzing these parameters has proved difficult due to the brittle nature of the fiber. In order to get clear pictures of the fiber cross sections, a clean cleave must be achieved. Shown below is the cross section of a 400-micron diameter high NA fiber.

Current work focuses on developing a dependable cleaving method in order to accurately measure the attenuation and NA of our drawn fibers. Also, attempts are being made to streamline preform preparation by switching from machining to preform extrusion.