Winter road maintenance often includes the use of deicing chemicals. However, many roadway deicing products are available, and their ice melting capacity can vary significantly. In addition, the processes that states use to procure and test deicing materials are subjective in measuring performance and are becoming increasingly burdensome for lab, procurement, and management staff. The objective of this project was to provide transportation agencies with an objective, standardized, repeatable laboratory test procedure for measuring the ice melting capacity of deicers.

Cumulative studies and years of experience have revealed weaknesses in the most commonly used ice melting test, H-205.2 (for liquid deicers), which was originally developed through the Strategic Highway Research Program (SHRP). In addition to having too much variance, the SHRP tests do not simulate any mechanical mixing during the process of ice melting by deicer. The Mechanical Rocker Ice Melting Test, developed by the Nebraska Department of Transportation, was intended to address these issues.

For this project, researchers evaluated the Mechanical Rocker Test Procedure for use as a national standard. They conducted a round robin test to examine the effects of rotational speed, test duration, tilt angle, and operating laboratory on the ice melting capacity (IMC) of ten liquid deicers measured with the Mechanical Rocker Ice Melting Test.

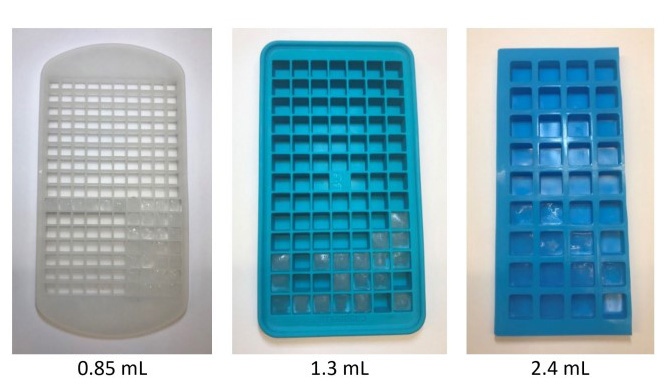

The researchers observed that changes in the average IMC values due to different rotational speeds, tilt angles, test durations, and the operating laboratory were not statistically significant. Ruggedness tests showed that the average IMC values did not change significantly as a result of a change in the shape of the thermos, the ice cube, or the volume of the ice cube. The most sensitive variable in this research was the operating laboratory.

To minimize the inter-laboratory variability introduced into the IMC test, the researchers proposed two data acceptance checks to be included. With these the Mechanical Rocker Ice Melting Test should be able to realistically and robustly assess the performance of deicers and allow transportation agencies to make data-driven procurement decisions.

As of 2024, AASHTO had provisionally approved the Mechanical Rocker Ice Melting test method.

Report CR 18-06

Final Project Webinar conducted March 2024

Authors:

Nazari, M.H.

Jamal, M.

Green, D.

Gonzalez, J.

Beaurivage, S.

Smith, H.

Mislang, J.

Potapova, A.

Akin, M.

Shi, X.

WSU Department of Civil and Environmental Engineering

Sponsors:

Clear Roads Pooled Fund

Minnesota Department of Transportation