2015 |

|

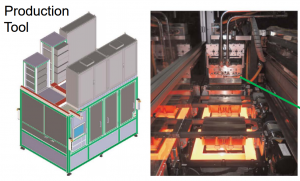

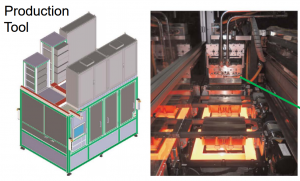

| Richter, Philipp L; Fischer, Gerd; Sylla, Lamine; Hentsche, Melanie; Steckemetz, Stefan; Müller, Matthias; Cobb, Corie L; Solberg, Scott E; Rao, Ranjeet; Elrod, Scott; Palinginis, Phedon; Schneiderlöchner, Eric; Neuhaus, Holger D Progress in fine-line metallization by co-extrusion printing on cast monosilicon PERC solar cells Journal Article In: Solar Energy Materials and Solar Cells, vol. 142, pp. 18–23, 2015, ISSN: 0927-0248. Abstract | Links | Tags: Co-extrusion, solar @article{richter_progress_2015,In this paper, we present our progress in co-extrusion printing for fine-line metallization. With this technique, 30µm wide and 20µm tall front grid fingers are currently printed. Applied to industrial size cast silicon PERC solar cells, a world record conversion efficiency of 21.42% has been demonstrated. This result was achieved with a production-ready co-extrusion printer that runs at a throughput of 2700 wafers per hour. Furthermore, a printhead is presented that has been developed to enable co-extrusion printing on pseudo-square wafers. Finally the cost advantage of the technology is discussed. |

2014 |

|

| Cobb, Corie Lynn; Solberg, Scott E Micro-extrusion printhead with offset orifices for generating gridlines on non-square substrates Patent US8875653 B2, 2014. Abstract | Links | Tags: Co-extrusion, solar @patent{cobb_micro-extrusion_2014,A solar cell extrusion printing system that uses a micro-extrusion printhead to print longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the gridline sets form step patterns on an octagonal (pseudo-square) substrate. The printhead includes a set of central nozzles that receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern. |

2013 |

|

| Cobb, Corie Lynn; Solberg, Scott E Method For Generating Gridlines On Non-Square Substrates Patent US20130206220A1, 2013. Abstract | Links | Tags: Co-extrusion, solar @patent{cobb_method_2013,A solar cell production method involves printing longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the two gridline sets form step patterns on octagonal (pseudo-square) substrates. A special printhead is used that includes a set of central nozzles which receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern. |

2012 |

|

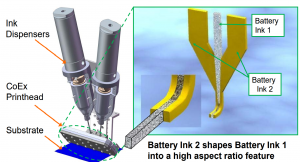

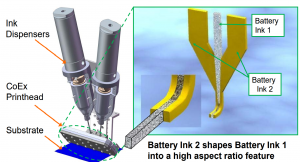

| Shrader, Eric J; Cobb, Corie L Co-Extrusion Printing for Low Cost and High Performance Energy Devices Proceedings Article In: Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy, pp. 537 – 540, NSTI, Santa Clara, CA, 2012, ISBN: 978-1-4665-6276-9. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries, solar @inproceedings{shrader_co-extrusion_2012,The method of co-extrusion of dissimilar materials has been developed at the PARC, a Xerox Company, to successfully produce high aspect ratio structures for solar cell gridlines. In the solar application, the process is stable and repeatable, and a fully integrated tool has been developed that is now being demonstrated at a customer site. The co-extrusion process is capable of non-contact, direct deposition of features as small as 1 – 10 um with aspect ratios in the range of 1:1 to 30:1. Alternating fluids are co-extruded to form a fine vertically interdigitated lamina structure. The relative thickness, width, and length of the deposited features can be varied by altering the printhead geometry and printing process conditions. |

2015 |

|

| Progress in fine-line metallization by co-extrusion printing on cast monosilicon PERC solar cells Journal Article In: Solar Energy Materials and Solar Cells, vol. 142, pp. 18–23, 2015, ISSN: 0927-0248. |

2014 |

|

| Micro-extrusion printhead with offset orifices for generating gridlines on non-square substrates Patent US8875653 B2, 2014. |

2013 |

|

| Method For Generating Gridlines On Non-Square Substrates Patent US20130206220A1, 2013. |

2012 |

|

| Co-Extrusion Printing for Low Cost and High Performance Energy Devices Proceedings Article In: Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy, pp. 537 – 540, NSTI, Santa Clara, CA, 2012, ISBN: 978-1-4665-6276-9. |