2018

|

| Cobb, Corie Lynn Structures for interdigitated finger co-extrusion Patent US9899669B2, 2018. @patent{cobb_structures_2018,

title = {Structures for interdigitated finger co-extrusion},

author = {Corie Lynn Cobb},

url = {https://patents.google.com/patent/US9899669B2/en},

year = {2018},

date = {2018-02-01},

urldate = {2018-03-14},

number = {US9899669B2},

abstract = {An electrode structure has an interdigitated layer of at least a first material and a second material, the second material having either higher or similar electrical conductivity of the first material and being more ionically conductivity than the first material, a cross-section of the two materials being non-rectangular.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

An electrode structure has an interdigitated layer of at least a first material and a second material, the second material having either higher or similar electrical conductivity of the first material and being more ionically conductivity than the first material, a cross-section of the two materials being non-rectangular. |

| Cobb, Corie Lynn Co-extrusion print head with edge bead reduction Patent US9855578B2, 2018. @patent{cobb_co-extrusion_2018,

title = {Co-extrusion print head with edge bead reduction},

author = {Corie Lynn Cobb},

url = {https://patents.google.com/patent/US9855578B2/en},

year = {2018},

date = {2018-01-01},

urldate = {2018-03-05},

number = {US9855578B2},

abstract = {A co-extrusion print head has at least one channel, and a set of orifices fluidically connected to the channel, wherein the set of orifices has at least one orifice at each edge of the set has a smaller vertical extent than the other orifices.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A co-extrusion print head has at least one channel, and a set of orifices fluidically connected to the channel, wherein the set of orifices has at least one orifice at each edge of the set has a smaller vertical extent than the other orifices. |

2017

|

| Cobb, Corie Lynn Co-extruded conformal battery separator and electrode Patent US9755221B2, 2017. @patent{cobb_co-extruded_2017,

title = {Co-extruded conformal battery separator and electrode},

author = {Corie Lynn Cobb},

url = {https://patents.google.com/patent/US9755221B2/en},

year = {2017},

date = {2017-09-01},

urldate = {2018-03-05},

number = {US9755221B2},

abstract = {A co-extrusion print head has at least one separator inlet port, at least a first, second and third series of channels arranged to receive a separator material from the separator inlet port, at least one electrode inlet port, a fourth series of channels arranged to receive an electrode material from the electrode inlet port, a first merge portion connected to the first, second, third and fourth series of channels, the merge portion positioned to receive and merge the separator material into a separator flow and the electrode material into an electrode flow, a second merge portion connected to the first merge portion, the second merge portion positioned to receive and merge the separator flows and the electrode flows, and an outlet port connected to the second merge portion, the outlet port arranged to deposit the separator and electrode materials from the merge portion as a stack on a substrate.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A co-extrusion print head has at least one separator inlet port, at least a first, second and third series of channels arranged to receive a separator material from the separator inlet port, at least one electrode inlet port, a fourth series of channels arranged to receive an electrode material from the electrode inlet port, a first merge portion connected to the first, second, third and fourth series of channels, the merge portion positioned to receive and merge the separator material into a separator flow and the electrode material into an electrode flow, a second merge portion connected to the first merge portion, the second merge portion positioned to receive and merge the separator flows and the electrode flows, and an outlet port connected to the second merge portion, the outlet port arranged to deposit the separator and electrode materials from the merge portion as a stack on a substrate. |

| Cobb, Corie Lynn; Bae, Chang-Jun Three dimensional co-extruded battery electrodes Patent US9590232B2, 2017. @patent{cobb_three_2017-1,

title = {Three dimensional co-extruded battery electrodes},

author = {Corie Lynn Cobb and Chang-Jun Bae},

url = {https://patents.google.com/patent/US9590232B2/en},

year = {2017},

date = {2017-03-01},

urldate = {2018-03-14},

number = {US9590232B2},

abstract = {A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction. |

| Cobb, Corie L; Solberg, Scott E Communication—Analysis of Thick Co-Extruded Cathodes for Higher-Energy-and-Power Lithium-Ion Batteries Journal Article In: Journal of The Electrochemical Society, vol. 164, no. 7, pp. A1339–A1341, 2017, ISSN: 0013-4651, 1945-7111. @article{cobb_communicationanalysis_2017,

title = {Communication—Analysis of Thick Co-Extruded Cathodes for Higher-Energy-and-Power Lithium-Ion Batteries},

author = {Corie L Cobb and Scott E Solberg},

url = {https://iopscience.iop.org/article/10.1149/2.0101707jes},

doi = {10.1149/2.0101707jes},

issn = {0013-4651, 1945-7111},

year = {2017},

date = {2017-01-01},

urldate = {2017-01-01},

journal = {Journal of The Electrochemical Society},

volume = {164},

number = {7},

pages = {A1339--A1341},

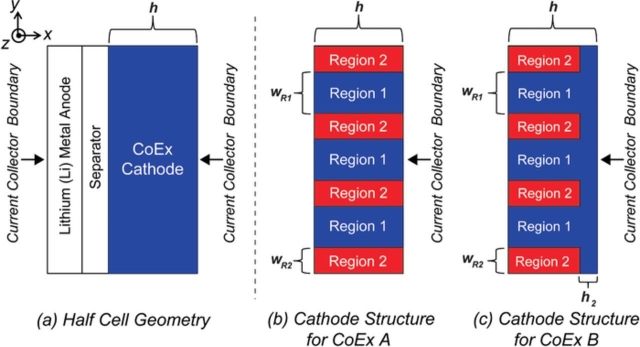

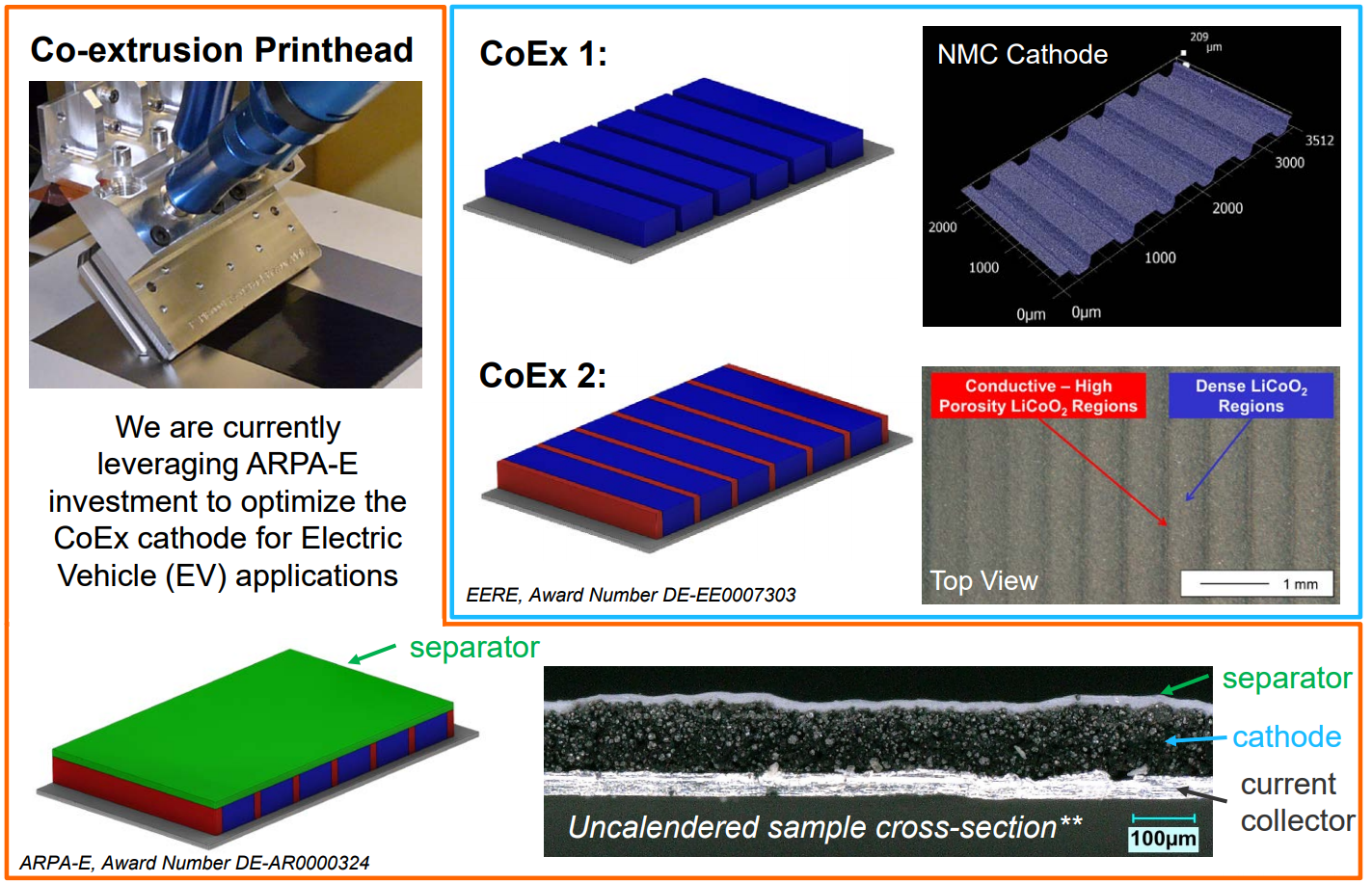

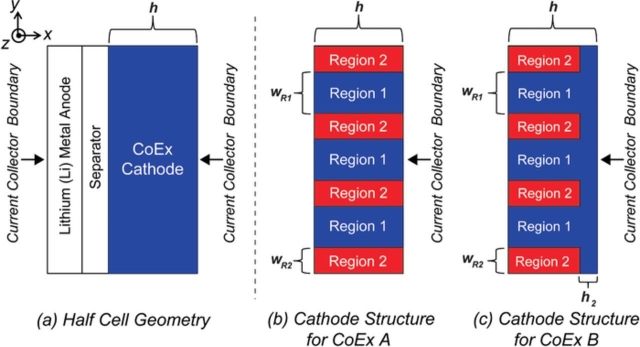

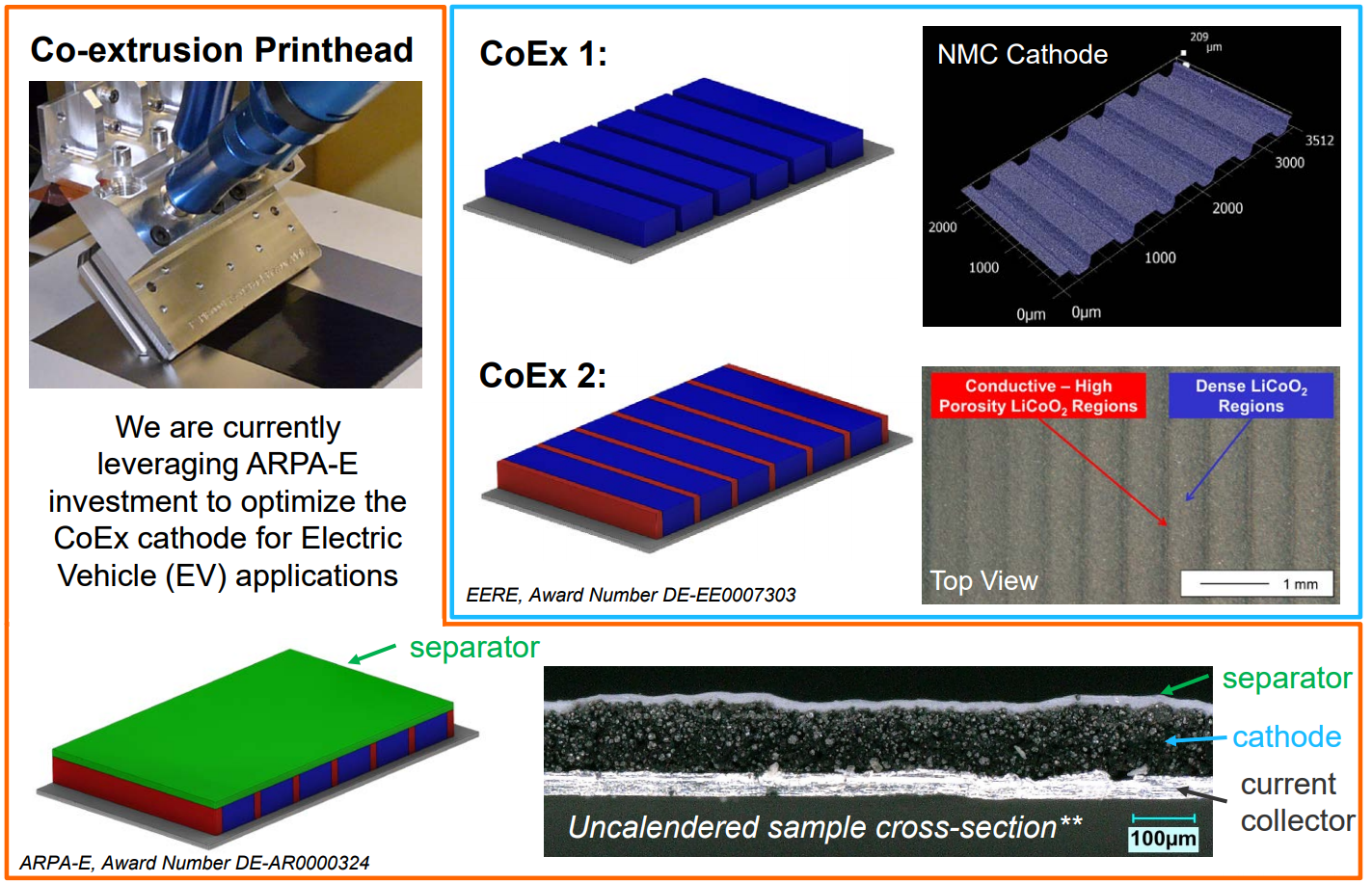

abstract = {3-dimensional (3D) electrode architectures have been explored as a means to decouple power and energy trade-offs in thick battery electrodes. Limited work has been published which systematically examines the impact of these architectures at the pouch cell level. This paper conducts an analysis on the potential capacity gains that can be realized with thick co-extruded electrodes in a pouch cell. Our findings show that despite lower active material composition for each cathode layer, the effective gain in thickness and active material loading enables pouch cell capacity gains greater than 10% with a Lithium Nickel Manganese Cobalt Oxide (NMC) materials system.},

keywords = {Co-extrusion},

pubstate = {published},

tppubtype = {article}

}

3-dimensional (3D) electrode architectures have been explored as a means to decouple power and energy trade-offs in thick battery electrodes. Limited work has been published which systematically examines the impact of these architectures at the pouch cell level. This paper conducts an analysis on the potential capacity gains that can be realized with thick co-extruded electrodes in a pouch cell. Our findings show that despite lower active material composition for each cathode layer, the effective gain in thickness and active material loading enables pouch cell capacity gains greater than 10% with a Lithium Nickel Manganese Cobalt Oxide (NMC) materials system. |

| Cobb, Corie Lynn; Bae, Chang-Jun Three dimensional co-extruded battery electrodes Patent US9793537B2, 2017. @patent{cobb_three_2017,

title = {Three dimensional co-extruded battery electrodes},

author = {Corie Lynn Cobb and Chang-Jun Bae},

url = {https://patents.google.com/patent/US9793537/en},

year = {2017},

date = {2017-01-01},

urldate = {2018-03-05},

number = {US9793537B2},

abstract = {A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction. |

2016

|

| Cobb, Corie Lynn Co-Extrusion: Advanced Manufacturing for Energy Devices Miscellaneous 2016. @misc{cobb_co-extrusion:_2016,

title = {Co-Extrusion: Advanced Manufacturing for Energy Devices},

author = {Corie Lynn Cobb},

url = {https://www.osti.gov/biblio/1333314},

year = {2016},

date = {2016-11-01},

urldate = {2018-03-14},

abstract = {The U.S. Department of Energy's Office of Scientific and Technical Information},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {misc}

}

The U.S. Department of Energy's Office of Scientific and Technical Information |

| Cobb, Corie Lynn Co-extrusion print head for multi-layer battery structures Patent US9337471 B2, 2016. @patent{cobb_co-extrusion_2016,

title = {Co-extrusion print head for multi-layer battery structures},

author = {Corie Lynn Cobb},

url = {http://www.google.com/patents/US9337471},

year = {2016},

date = {2016-01-01},

urldate = {2017-09-13},

number = {US9337471 B2},

abstract = {A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate. |

2015

|

| Richter, Philipp L; Fischer, Gerd; Sylla, Lamine; Hentsche, Melanie; Steckemetz, Stefan; Müller, Matthias; Cobb, Corie L; Solberg, Scott E; Rao, Ranjeet; Elrod, Scott; Palinginis, Phedon; Schneiderlöchner, Eric; Neuhaus, Holger D Progress in fine-line metallization by co-extrusion printing on cast monosilicon PERC solar cells Journal Article In: Solar Energy Materials and Solar Cells, vol. 142, pp. 18–23, 2015, ISSN: 0927-0248. @article{richter_progress_2015,

title = {Progress in fine-line metallization by co-extrusion printing on cast monosilicon PERC solar cells},

author = {Philipp L Richter and Gerd Fischer and Lamine Sylla and Melanie Hentsche and Stefan Steckemetz and Matthias Müller and Corie L Cobb and Scott E Solberg and Ranjeet Rao and Scott Elrod and Phedon Palinginis and Eric Schneiderlöchner and Holger D Neuhaus},

url = {http://www.sciencedirect.com/science/article/pii/S0927024815002287},

doi = {10.1016/j.solmat.2015.05.023},

issn = {0927-0248},

year = {2015},

date = {2015-11-01},

urldate = {2018-03-05},

journal = {Solar Energy Materials and Solar Cells},

volume = {142},

pages = {18--23},

series = {Proceedings of the 5th International Conference on Crystalline Silicon Photovoltaics (SiliconPV 2015)},

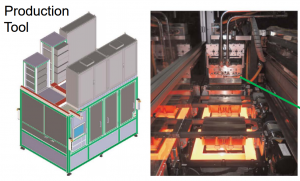

abstract = {In this paper, we present our progress in co-extrusion printing for fine-line metallization. With this technique, 30µm wide and 20µm tall front grid fingers are currently printed. Applied to industrial size cast silicon PERC solar cells, a world record conversion efficiency of 21.42% has been demonstrated. This result was achieved with a production-ready co-extrusion printer that runs at a throughput of 2700 wafers per hour. Furthermore, a printhead is presented that has been developed to enable co-extrusion printing on pseudo-square wafers. Finally the cost advantage of the technology is discussed.},

keywords = {Co-extrusion, solar},

pubstate = {published},

tppubtype = {article}

}

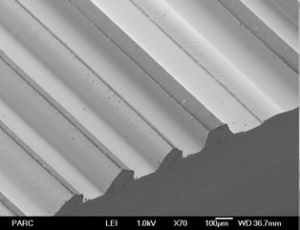

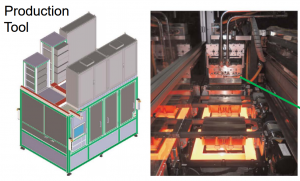

In this paper, we present our progress in co-extrusion printing for fine-line metallization. With this technique, 30µm wide and 20µm tall front grid fingers are currently printed. Applied to industrial size cast silicon PERC solar cells, a world record conversion efficiency of 21.42% has been demonstrated. This result was achieved with a production-ready co-extrusion printer that runs at a throughput of 2700 wafers per hour. Furthermore, a printhead is presented that has been developed to enable co-extrusion printing on pseudo-square wafers. Finally the cost advantage of the technology is discussed. |

2014

|

| Cobb, Corie Lynn Co-extrusion print head for multi-layer battery structures Patent US20140186519A1, 2014. @patent{cobb_co-extrusion_2014,

title = {Co-extrusion print head for multi-layer battery structures},

author = {Corie Lynn Cobb},

url = {https://patents.google.com/patent/US20140186519A1/en},

year = {2014},

date = {2014-07-01},

urldate = {2018-03-14},

number = {US20140186519A1},

abstract = {A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate. |

| Cobb, Corie L; Blanco, Mario Modeling mass and density distribution effects on the performance of co-extruded electrodes for high energy density lithium-ion batteries Journal Article In: Journal of Power Sources, vol. 249, pp. 357–366, 2014, ISSN: 0378-7753. @article{cobb_modeling_2014,

title = {Modeling mass and density distribution effects on the performance of co-extruded electrodes for high energy density lithium-ion batteries},

author = {Corie L Cobb and Mario Blanco},

url = {http://www.sciencedirect.com/science/article/pii/S0378775313017503},

doi = {10.1016/j.jpowsour.2013.10.084},

issn = {0378-7753},

year = {2014},

date = {2014-01-01},

urldate = {2017-09-13},

journal = {Journal of Power Sources},

volume = {249},

pages = {357--366},

abstract = {Utilizing an existing macro-homogeneous porous electrode model developed by John Newman, this paper aims to explore the potential energy density gains which can be realized in lithium-ion battery electrodes fabricated with co-extrusion printing technology. This paper conducts an analysis on two-dimensional electrode cross-sections and presents the electrochemical performance results, including calculated volumetric energy capacity for a general class of lithium cobalt oxide (LiCoO2) co-extruded cathodes, in the presence of a lithium metal anode, polymer separator and liquid ethylene carbonate, propylene carbonate, and dimethyl carbonate (EC:PC:DMC) electrolyte. The impact of structured electrodes on cell performance is investigated by varying the physical distribution of a fixed amount of cathode mass over a space of dimensions which can be fabricated by co-extrusion. By systematically varying the thickness and aspect ratio of the electrode structures, we present an optimal subset of geometries and design rules for co-extruded geometries. Modeling results demonstrate that ultra-thick LiCoO2 electrodes, on the order of 150–300 μm, can garner a substantial improvement in material utilization and in turn capacity through electrolyte channels and fine width electrode pillars which are 25–100 μm wide.},

keywords = {battery modeling, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {article}

}

Utilizing an existing macro-homogeneous porous electrode model developed by John Newman, this paper aims to explore the potential energy density gains which can be realized in lithium-ion battery electrodes fabricated with co-extrusion printing technology. This paper conducts an analysis on two-dimensional electrode cross-sections and presents the electrochemical performance results, including calculated volumetric energy capacity for a general class of lithium cobalt oxide (LiCoO2) co-extruded cathodes, in the presence of a lithium metal anode, polymer separator and liquid ethylene carbonate, propylene carbonate, and dimethyl carbonate (EC:PC:DMC) electrolyte. The impact of structured electrodes on cell performance is investigated by varying the physical distribution of a fixed amount of cathode mass over a space of dimensions which can be fabricated by co-extrusion. By systematically varying the thickness and aspect ratio of the electrode structures, we present an optimal subset of geometries and design rules for co-extruded geometries. Modeling results demonstrate that ultra-thick LiCoO2 electrodes, on the order of 150–300 μm, can garner a substantial improvement in material utilization and in turn capacity through electrolyte channels and fine width electrode pillars which are 25–100 μm wide. |

| Cobb, Corie Lynn; Solberg, Scott E Micro-extrusion printhead with offset orifices for generating gridlines on non-square substrates Patent US8875653 B2, 2014. @patent{cobb_micro-extrusion_2014,

title = {Micro-extrusion printhead with offset orifices for generating gridlines on non-square substrates},

author = {Corie Lynn Cobb and Scott E Solberg},

url = {http://www.google.com/patents/US8875653},

year = {2014},

date = {2014-01-01},

urldate = {2017-09-13},

number = {US8875653 B2},

abstract = {A solar cell extrusion printing system that uses a micro-extrusion printhead to print longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the gridline sets form step patterns on an octagonal (pseudo-square) substrate. The printhead includes a set of central nozzles that receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern.},

keywords = {Co-extrusion, solar},

pubstate = {published},

tppubtype = {patent}

}

A solar cell extrusion printing system that uses a micro-extrusion printhead to print longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the gridline sets form step patterns on an octagonal (pseudo-square) substrate. The printhead includes a set of central nozzles that receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern. |

| Bae, Chang-Jun; Shrader, Eric J; Cobb, Corie Lynn Advanced, high power and energy battery electrode manufactured by co-extrusion printing Patent US20140186700A1, 2014. @patent{bae_advanced_2014,

title = {Advanced, high power and energy battery electrode manufactured by co-extrusion printing},

author = {Chang-Jun Bae and Eric J Shrader and Corie Lynn Cobb},

url = {https://patents.google.com/patent/US20140186700A1/en?inventor=Corie+Lynn+Cobb},

year = {2014},

date = {2014-01-01},

urldate = {2018-03-05},

number = {US20140186700A1},

abstract = {A battery has an anode, a separator adjacent the anode, and a cathode adjacent the separator opposite the anode, the cathode comprising interdigitated stripes of materials, one of the materials forming a pore channel.},

keywords = {additive manufacturing, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {patent}

}

A battery has an anode, a separator adjacent the anode, and a cathode adjacent the separator opposite the anode, the cathode comprising interdigitated stripes of materials, one of the materials forming a pore channel. |

2013

|

| Cobb, Corie Lynn; Solberg, Scott E Method For Generating Gridlines On Non-Square Substrates Patent US20130206220A1, 2013. @patent{cobb_method_2013,

title = {Method For Generating Gridlines On Non-Square Substrates},

author = {Corie Lynn Cobb and Scott E Solberg},

url = {https://patents.google.com/patent/US20130206220A1/en},

year = {2013},

date = {2013-08-01},

urldate = {2018-03-13},

number = {US20130206220A1},

abstract = {A solar cell production method involves printing longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the two gridline sets form step patterns on octagonal (pseudo-square) substrates. A special printhead is used that includes a set of central nozzles which receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern.},

keywords = {Co-extrusion, solar},

pubstate = {published},

tppubtype = {patent}

}

A solar cell production method involves printing longer central gridlines and one or more pairs of shorter “side” gridlines such that end points of the two gridline sets form step patterns on octagonal (pseudo-square) substrates. A special printhead is used that includes a set of central nozzles which receive ink from a first valve by way of a first flow channel to print the longer central gridlines, and additional sets of side nozzles that receive ink from additional valves by way of additional flow channels to print the shorter “side” gridlines. The central nozzles have outlet orifices that offset in the process direction from side outlet orifices of the side nozzles. A start signal is simultaneously sent to the valves such that ink is substantially simultaneously extruded through both the central and side orifices, whereby the extruded ink produces gridline endpoints having the desired step pattern. |

2012

|

| Shrader, Eric J; Cobb, Corie L Co-Extrusion Printing for Low Cost and High Performance Energy Devices Proceedings Article In: Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy, pp. 537 – 540, NSTI, Santa Clara, CA, 2012, ISBN: 978-1-4665-6276-9. @inproceedings{shrader_co-extrusion_2012,

title = {Co-Extrusion Printing for Low Cost and High Performance Energy Devices},

author = {Eric J Shrader and Corie L Cobb},

url = {http://www.nsti.org/procs/Nanotech2012v3/8/T8.174},

isbn = {978-1-4665-6276-9},

year = {2012},

date = {2012-01-01},

urldate = {2018-03-05},

booktitle = {Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy},

volume = {3},

pages = {537 -- 540},

publisher = {NSTI},

address = {Santa Clara, CA},

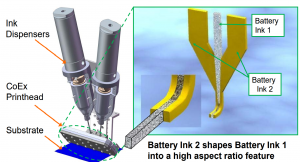

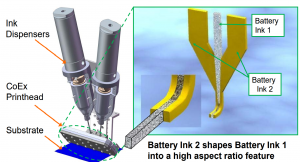

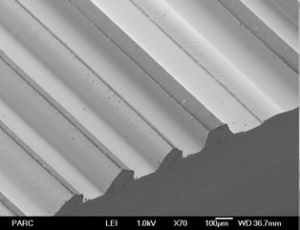

abstract = {The method of co-extrusion of dissimilar materials has been developed at the PARC, a Xerox Company, to successfully produce high aspect ratio structures for solar cell gridlines. In the solar application, the process is stable and repeatable, and a fully integrated tool has been developed that is now being demonstrated at a customer site. The co-extrusion process is capable of non-contact, direct deposition of features as small as 1 – 10 um with aspect ratios in the range of 1:1 to 30:1. Alternating fluids are co-extruded to form a fine vertically interdigitated lamina structure. The relative thickness, width, and length of the deposited features can be varied by altering the printhead geometry and printing process conditions.},

keywords = {additive manufacturing, Co-extrusion, printed batteries, solar},

pubstate = {published},

tppubtype = {inproceedings}

}

The method of co-extrusion of dissimilar materials has been developed at the PARC, a Xerox Company, to successfully produce high aspect ratio structures for solar cell gridlines. In the solar application, the process is stable and repeatable, and a fully integrated tool has been developed that is now being demonstrated at a customer site. The co-extrusion process is capable of non-contact, direct deposition of features as small as 1 – 10 um with aspect ratios in the range of 1:1 to 30:1. Alternating fluids are co-extruded to form a fine vertically interdigitated lamina structure. The relative thickness, width, and length of the deposited features can be varied by altering the printhead geometry and printing process conditions. |

2011

|

| Littau, Karl A; Cobb, Corie L; Spengler, Nils; Solberg, Scott; Weisberg, Michael; Chang, Norinne; Rodkin, Alexandra Developments in MEMS scale printable alkaline and Li-ion technology Proceedings Article In: Micro- and Nanotechnology Sensors, Systems, and Applications III, pp. 80311L, International Society for Optics and Photonics, 2011. @inproceedings{littau_developments_2011,

title = {Developments in MEMS scale printable alkaline and Li-ion technology},

author = {Karl A Littau and Corie L Cobb and Nils Spengler and Scott Solberg and Michael Weisberg and Norinne Chang and Alexandra Rodkin},

url = {https://www.spiedigitallibrary.org/conference-proceedings-of-spie/8031/80311L/Developments-in-MEMS-scale-printable-alkaline-and-Li-ion-technology/10.1117/12.883311.short},

doi = {10.1117/12.883311},

year = {2011},

date = {2011-05-01},

urldate = {2018-03-05},

booktitle = {Micro- and Nanotechnology Sensors, Systems, and Applications III},

volume = {8031},

pages = {80311L},

publisher = {International Society for Optics and Photonics},

abstract = {Two technologies for MEMS (Microelectromechanical Systems) scale cell formation are discussed. First, the fabrication of planar alkaline cell batteries compatible with MEMS scale power storage applications is shown. Both mm scale and sub-mm scale individual cells and batteries have been constructed. The chosen coplanar electrode geometry allows for easy fabrication of series connected cells enabling higher voltage while simplifying the cell sealing and electrode formation. The Zn/Ag alkaline system is used due to the large operating voltage, inherent charge capacity, long shelf life, and ease of fabrication. Several cells have been constructed using both plated and spun-on silver. The plated cells are shown to be limited in performance due to inadequate surface area and porosity; however, the cells made from spun-on colloidal silver show reasonable charge capacity and power performance with current densities of up to 200 uA/mm$^textrm2$ and charge capacities of up to 18 mA-s/mm$^textrm2$. Second, a new printing method for interdigitated 3-D cells is introduced. A microfluidic printhead capable of dispensing multiple materials at high resolution and aspect ratio is described and used to form fine interdigitated cell features which show >10 times improvement in energy density. Representative structures enabled by this method are modeled, and the energy and power density improvements are reported.},

keywords = {additive manufacturing, Co-extrusion, MEMS, printed batteries},

pubstate = {published},

tppubtype = {inproceedings}

}

Two technologies for MEMS (Microelectromechanical Systems) scale cell formation are discussed. First, the fabrication of planar alkaline cell batteries compatible with MEMS scale power storage applications is shown. Both mm scale and sub-mm scale individual cells and batteries have been constructed. The chosen coplanar electrode geometry allows for easy fabrication of series connected cells enabling higher voltage while simplifying the cell sealing and electrode formation. The Zn/Ag alkaline system is used due to the large operating voltage, inherent charge capacity, long shelf life, and ease of fabrication. Several cells have been constructed using both plated and spun-on silver. The plated cells are shown to be limited in performance due to inadequate surface area and porosity; however, the cells made from spun-on colloidal silver show reasonable charge capacity and power performance with current densities of up to 200 uA/mm$^textrm2$ and charge capacities of up to 18 mA-s/mm$^textrm2$. Second, a new printing method for interdigitated 3-D cells is introduced. A microfluidic printhead capable of dispensing multiple materials at high resolution and aspect ratio is described and used to form fine interdigitated cell features which show >10 times improvement in energy density. Representative structures enabled by this method are modeled, and the energy and power density improvements are reported. |