2025 |

|

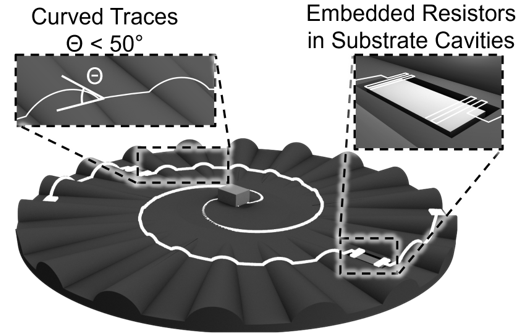

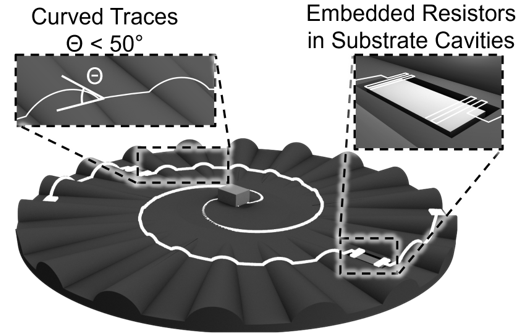

| Nguyen, Vinh; Harding, Anika E.; Yan, Kaito; Peek, Nadya; Cobb, Corie L. Jitterbug: A Hybrid Digital Fabrication Platform for Rapid Prototyping of Printed Electronics Proceedings Article In: ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASME, 2025. Abstract | Links | Tags: additive manufacturing, digital fabrication, printed electronics @inproceedings{nguyen_jitterbug_2023,Hybrid digital fabrication combines 3D printing with additional fabrication functionality such as pick-and-place (PnP) to enable customizable, printed electronic (PE) devices with an expansive array of form factors. Researchers have investigated a wide range of new materials, methods, and processes to advance PE devices. However, existing platforms cannot be easily modified or customized, severely limiting one’s ability to adapt hybrid digital fabrication platforms to ever evolving research and prototype needs. This paper introduces Jitterbug, a hybrid digital fabrication platform that supports rapid prototyping of PEs. Jitterbug consists of a toolpath generation workflow and an automatic tool-changing hardware system that builds upon existing open-source 3-axis motion frameworks. The toolpath generation workflow allows users to design PEs and generate toolpath programs directly in its computer-aided design (CAD) environment, provides granular control of the fabrication workflow, and enables printing of conductive traces on substrates with curved features at low-incline angles (< 50°). For demonstration purposes, Jitterbug's initial tool-changing system is designed with the core fused filament fabrication (FFF), direct ink writing (DIW), and PnP tools necessary for hybrid digital fabrication; the system can support up to ten tools for different PE workflows. Jitterbug’s capabilities are demonstrated through fabrication of two functional light-emitting diode (LED) prototype devices, and its implications on designing specialized workflows for PEs are discussed. |

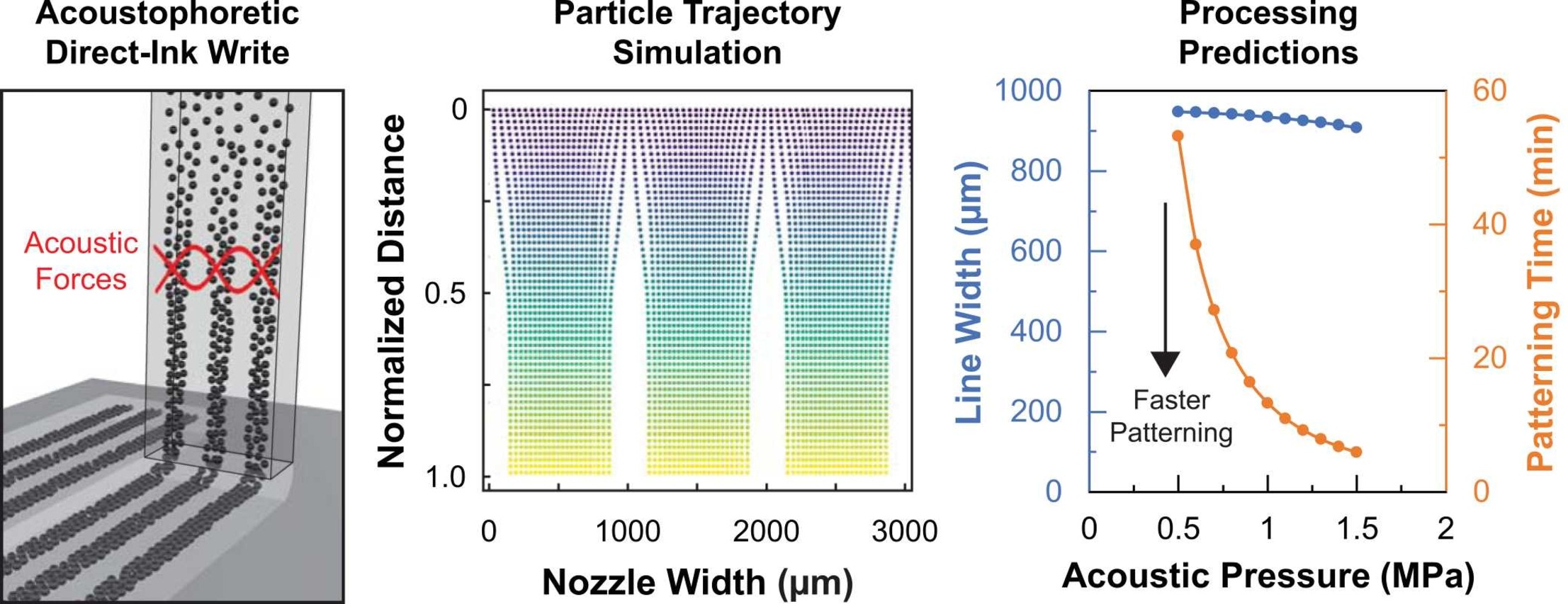

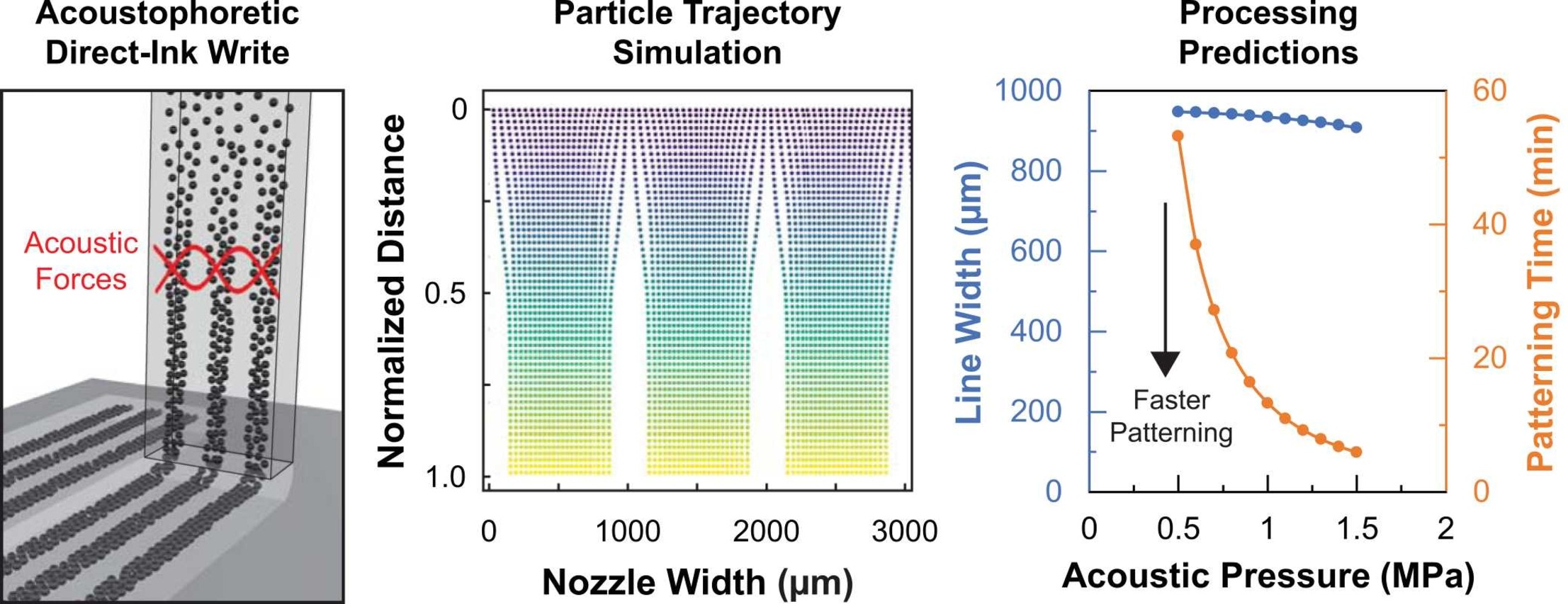

| Armstrong, Emilee N.; Johnson, Keith E.; Herbruger, Kyle A.; Sanchez, Austin K.; Begley, Matthew R.; Cobb, Corie L. In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. Abstract | Links | Tags: 3D printing, acoustic focusing, acoustophoresis, additive manufacturing @article{armstrong_predicting_2025,Patterned functional materials offer improved properties (electrical, thermal, etc.) over their bulk counterparts in many applications, including energy storage, flexible electronics, and sensors. However, manufacturing approaches for patterning materials over large areas with features on the order of hundreds of microns or less are limited. Acoustophoresis, which uses acoustic forces to control particle arrangement in a fluid medium, is a pathway to address this challenge. This process is dependent on particle and fluid properties and enables patterning of a broad range of materials. Herein, a model with experimental validation is presented to demonstrate that acoustophoresis can be combined with direct-ink writing (DIW) to fabricate line patterns over large cm-scale areas. An in-nozzle particle interaction model was developed to investigate the impact of processing conditions on multi-nodal acoustophoretic DIW. The model predicts patterned line widths within a factor of two relative to experimental results for a high viscosity case study. The model was used to investigate the impact of frequency, particle loading, particle radius, and acoustic pressure on line width and patterning time, providing critical feedback regarding the processing conditions suitable for a target application. Model results illustrate that frequency has the greatest impact on line patterns: increasing from 1 to 3MHz resulted in a greater than 65% reduction in line width and a greater than 85% reduction in patterning time. Additionally, experiments were conducted with an alumina-epoxy ink, and a textasciitilde21 cm2 area pattern was rastered in textasciitilde5.5minutes, demonstrating a path towards large-area line-patterned composite fabrication. |

2024 |

|

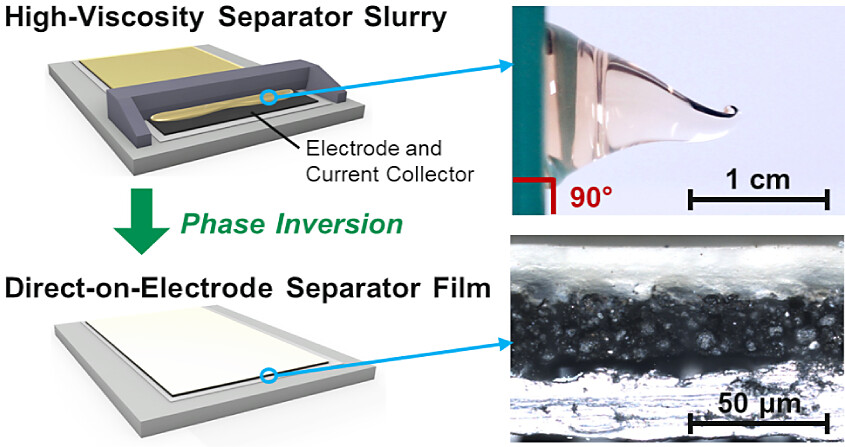

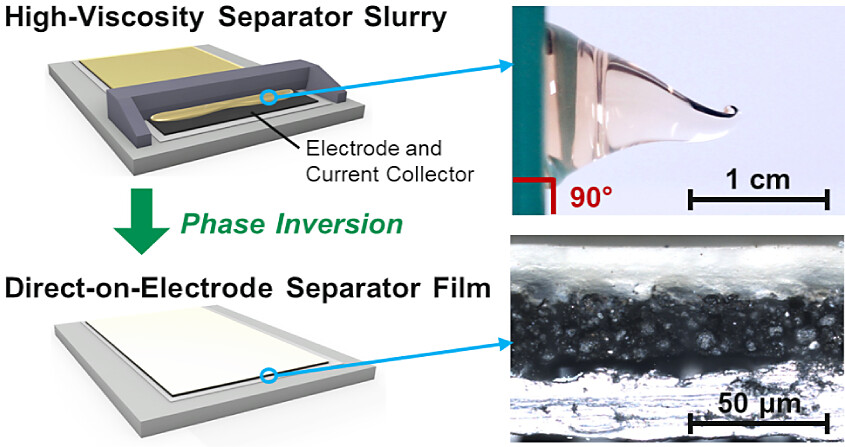

| Katz, Michelle E. R.; Cobb, Corie L. High-Viscosity Phase Inversion Separators for Freestanding and Direct-on-Electrode Manufacturing in Lithium-Ion Batteries Journal Article In: ACS Applied Materials & Interfaces, vol. 16, no. 34, pp. 44863–44878, 2024, ISSN: 1944-8244, (Publisher: American Chemical Society). Abstract | Links | Tags: additive manufacturing, batteries, printed batteries @article{katz_high-viscosity_2024,Separators play a critical role in lithium-ion batteries (LIBs) by facilitating lithium-ion (Li-ion) transport while enabling safe battery operation. However, commercial separators made from polypropylene (PP) or polyethylene (PE) impose a discrete processing step in current LIB manufacturing as they cannot be manufactured with the same slot-die coating process used to fabricate the electrodes. Moreover, commercial separators cannot accommodate newer manufacturing processes used to produce leading-edge microbatteries and flexible batteries with customized form factors. As a path toward rethinking LIB fabrication, we have developed a high-viscosity polymer composite separator slurry that enables the fabrication of both freestanding and direct-on-electrode films. A streamlined phase inversion process is used to impart porosity in cast separator films upon drying. To understand the impacts of material composition and rheology on phase inversion processing and separator performance, we investigated four different separator formulations. We used either diethylene glycol (DEG) or triethyl phosphate (TEP) as a nonsolvent, and either silica (SiO2) or alumina (Al2O3) as an inorganic additive in a polyvinylidene fluoride-co-hexafluoropropylene (PVDF-HFP) matrix. Through a down-selection process, we developed a TEP-SiO2 separator formulation that matched or outperformed a commercial Celgard 2325 (PP/PE/PP) separator and a Beyond Battery ceramic-coated PE (CC/PE/CC) separator under rate and cycle life tests in LiFePO4textbarLi4Ti5O12 (LFPtextbarLTO) and LiNi0.5Mn0.3Co0.2O2textbargraphite (NMC-532textbargraphite) coin cells at C/10–1C rates. Our TEP-SiO2 slurry had a viscosity of 298 Pa s at a 1 s–1 shear rate and shear-thinning behavior. When deposited directly onto an LTO anode and cycled against an LFP cathode, the direct-on-electrode TEP-SiO2 separator increased the specific capacity by 58% and 304% at 2C rates relative to the PP/PE/PP and CC/PE/CC separators, respectively. Additionally, the freestanding TEP-SiO2 separator maintained dimensional stability when heated to 200 °C for 1 h and demonstrated a higher elastic modulus and hardness than the PP/PE/PP and CC/PE/CC separators when measured with nanoindentation. |

2023 |

|

| Cobb, Corie L.; Katz, Michelle E. R. Engineering advanced Lithium-ion batteries with additive manufacturing Book Chapter In: Li, Jianlin; Jin, Congrui (Ed.): Processing and Manufacturing of Electrodes for Lithium-Ion Batteries, pp. 129–168, IET Digital Library, 2023, ISBN: 9781839536694. Abstract | Links | Tags: 3D printing, additive manufacturing, batteries @inbook{cobb_engineering_2023,Additive manufacturing (AM) enables the fabrication of complex shapes and formfactors that are inefficient or impossible to produce with traditional subtractive machining tools. AM emerged in the 1980s to enable the rapid creation of functional prototypes (also known as rapid prototyping). The first commercial implementation of AM was a stereolithography (SLA) system developed by 3D Systems in 1987, wherein a laser solidified thin layers of a photoactive polymer solution. In the early 1990s, fused deposition modeling (FDM), selective laser sintering, and other AM modalities began to emerge and have continued to grow in the decades since. Within the last ten years, AM has gained traction as an approach to fabricate Lithium-ion batteries (LIBs) because it enables (1) novel three-dimensional (3D) electrodes that optimize energy and power performance and (2) customizable battery shapes for integrated and mechanically robust batteries for portable device applications. As energy storage demands grow, so does the need for LIBs to come in a multitude of sizes, shapes, and materials that meet the needs of a given application. In this chapter, we review the main AM approaches that have been used to produce LIBs with a focus on FDM, direct-ink write (DIW), inkjet printing (IJP), aerosol jet printing (AJP), electrostatic spray deposition (ESD), stereolithography (SLA), and newer field-assisted (FA) methods. |

2021 |

|

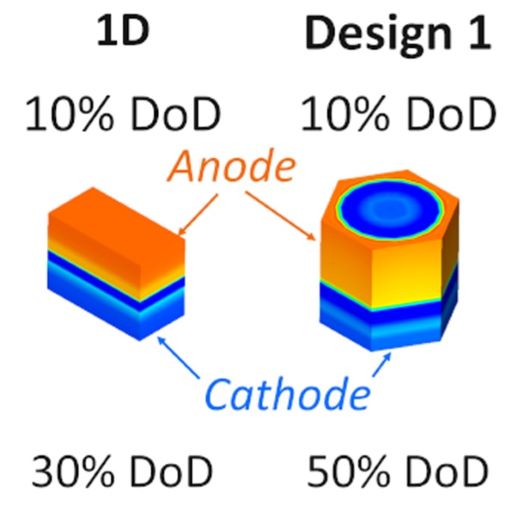

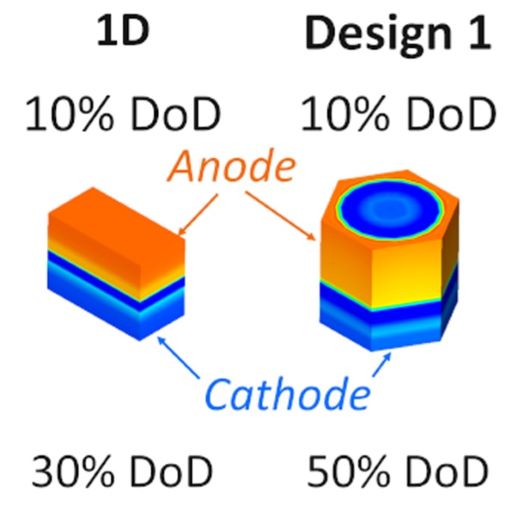

| Hung, Chih-Hsuan; Allu, Srikanth; Cobb, Corie L Modeling Current Density Non-Uniformities to Understand High-Rate Limitations in 3D Interdigitated Lithium-ion Batteries Journal Article In: Journal of The Electrochemical Society, vol. 168, no. 10, pp. 100512, 2021, ISSN: 1945-7111, (Publisher: The Electrochemical Society). Abstract | Links | Tags: additive manufacturing, battery modeling @article{hung_modeling_2021,Conventional planar Lithium-ion battery (LIB) cells are composed of a cathode and an anode with a polymer separator sheet sandwiched in between. Three-dimensional (3D) interdigitated batteries, where an anode and a cathode are intertwined, have been proposed as an alternative to planar LIBs to significantly improve energy, power, and fast charge performance. Various 3D battery designs have been demonstrated by researchers over the years, but a systematic study of how architecture and material impact 3D battery performance has been limited. In this paper, we conduct a comparative 3D computational modeling study on four 3D interdigitated battery designs previously shown in literature. We model each 3D battery using Li4Ti5O12 (LTO)∣LiFePO4 (LFP) and Graphite∣LiNi0.5Mn0.3Co0.2O2 (NMC), two widely studied LIB material systems, while conserving mass across all designs. Moreover, we propose a 3D current density metric to evaluate 3D LIBs and quantify the impact of current non-uniformities on high-rate LIB performance. Our results indicate that material selection and 3D architecture are equally critical for maximizing performance at high discharge rates. In addition, our analysis suggests quantifying the rate of change in current density early in a model discharge cycle can be a guiding metric to screen designs more quickly for premature failure. |

| Melchert, Drew S; Johnson, Keith; Giera, Brian; Fong, Erika J; Shusteff, Maxim; Mancini, Julie; Karnes, John J; Cobb, Corie L; Spadaccini, Christopher; Gianola, Daniel S; Begley, Matthew R Modeling meso- and microstructure in materials patterned with acoustic focusing Journal Article In: Materials & Design, pp. 109512, 2021, ISSN: 0264-1275. Abstract | Links | Tags: additive manufacturing, architected materials, composite materials @article{melchert_modeling_2021,We conduct numerical simulations of acoustic focusing in dense suspensions to map the design space of acoustically patterned materials. We develop closed-form expressions for acoustic forces on particles, enabling rapid simulation of thousands of particles, and find excellent agreement with experimentally focused patterns over a range of conditions. We map the geometrical and microstructural features of focused particle patterns and their dependence on processing parameters. We find that mesostructural geometrical features (focused line height, width, and profile shape) can be controlled reliably over a broad range by modulating input parameters, and that while microstructural features are less readily modulated via input parameters, they are well-suited for various transport properties in functional materials. Notably, packing density nears the random close packing limit at 0.64, and particle contact density shows anisotropy favoring particle contacts along the focused lines. These results guide process design for controlling the properties of patterned materials, and outline the property ranges accessible via acoustic focusing. Additionally, we discuss the dependence of material functionalities, particularly electrical, thermal, and ionic transport properties, on the meso- and micro-structural features of patterned composite materials in the context of acoustic focusing. |

2018 |

|

| Cobb, Corie Lynn Structures for interdigitated finger co-extrusion Patent US9899669B2, 2018. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_structures_2018,An electrode structure has an interdigitated layer of at least a first material and a second material, the second material having either higher or similar electrical conductivity of the first material and being more ionically conductivity than the first material, a cross-section of the two materials being non-rectangular. |

| Johnson, David Mathew; Cobb, Corie Lynn; Paschkewitz, John Steven Integral vasculature Patent US9884437B2, 2018. Abstract | Links | Tags: additive manufacturing, composite materials @patent{johnson_integral_2018,A system and method is provided for creating a structure including a vasculature network. A film deposition device is configured to dispense droplets onto a surface of a substrate to form a curable fugitive pre-patterned liquid film on the surface of the substrate. An electrohydrodynamic film patterning (EHD-FP) device has a patterned electrode structure formed to generate an electric field and to subject the film on the surface of the substrate to the electric field. The film thereby being formed by the EHD-FP into patterned features in response to being subjected to the electric field. Then a casting system is configured to cover the patterned features in an epoxy to form patterned structures, wherein the patterned structures comprise a fugitive vasculature structure. |

| Cobb, Corie Lynn Co-extrusion print head with edge bead reduction Patent US9855578B2, 2018. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_co-extrusion_2018,A co-extrusion print head has at least one channel, and a set of orifices fluidically connected to the channel, wherein the set of orifices has at least one orifice at each edge of the set has a smaller vertical extent than the other orifices. |

2017 |

|

| Cobb, Corie Lynn Co-extruded conformal battery separator and electrode Patent US9755221B2, 2017. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_co-extruded_2017,A co-extrusion print head has at least one separator inlet port, at least a first, second and third series of channels arranged to receive a separator material from the separator inlet port, at least one electrode inlet port, a fourth series of channels arranged to receive an electrode material from the electrode inlet port, a first merge portion connected to the first, second, third and fourth series of channels, the merge portion positioned to receive and merge the separator material into a separator flow and the electrode material into an electrode flow, a second merge portion connected to the first merge portion, the second merge portion positioned to receive and merge the separator flows and the electrode flows, and an outlet port connected to the second merge portion, the outlet port arranged to deposit the separator and electrode materials from the merge portion as a stack on a substrate. |

| Ng, Tse Nga; Mei, Ping; Cobb, Corie Lynn; Ready, Steven E; Paschkewitz, John S Structural designs for stretchable, conformal electrical interconnects Patent US20170215284A1, 2017. Abstract | Links | Tags: additive manufacturing, printed electronics @patent{ng_structural_2017,Disclosed is a conformable, stretchable and electrical conductive structure, which includes an auxetic structure, and a plurality of electrical conductors. The plurality of electrical conductors being incorporated within the auxetic structure, to form conformable, stretchable electrical interconnects, configured based on a design of the auxetic structure and placement of the electrical conductors incorporated with the auxetic structure. |

| Cobb, Corie Lynn; Bae, Chang-Jun Three dimensional co-extruded battery electrodes Patent US9590232B2, 2017. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_three_2017-1,A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction. |

| Paschkewitz, John Steven; Cobb, Corie Lynn; Johnson, David Mathew; Iftime, Gabriel; Beck, Victor Alfred; Ng, Tse Nga; Rao, Ranjeet US9543495B2, 2017. Abstract | Links | Tags: additive manufacturing, printed electronics, wearables @patent{paschkewitz_method_2017,A method of forming a flexible thermal regulation device having multiple functional layers. The layers of the device are formed using various manufacturing techniques and are then integrated to form a sheet having multiple devices disposed thereon. The individual devices are then formed from the sheet. |

| Cobb, Corie Lynn; Bae, Chang-Jun Three dimensional co-extruded battery electrodes Patent US9793537B2, 2017. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_three_2017,A three dimensional electrode structure having a first layer of interdigitated stripes of material oriented in a first direction, and a second layer of interdigitated stripes of material oriented in a second direction residing on the first layer of interdigitated stripes of material. A method of manufacturing a three dimensional electrode structure includes depositing a first layer of interdigitated stripes of an active material and an intermediate material on a substrate in a first direction, and depositing a second layer of interdigitated stripes of the active material and the intermediate material on the first layer in a second direction orthogonal to the first direction. |

2016 |

|

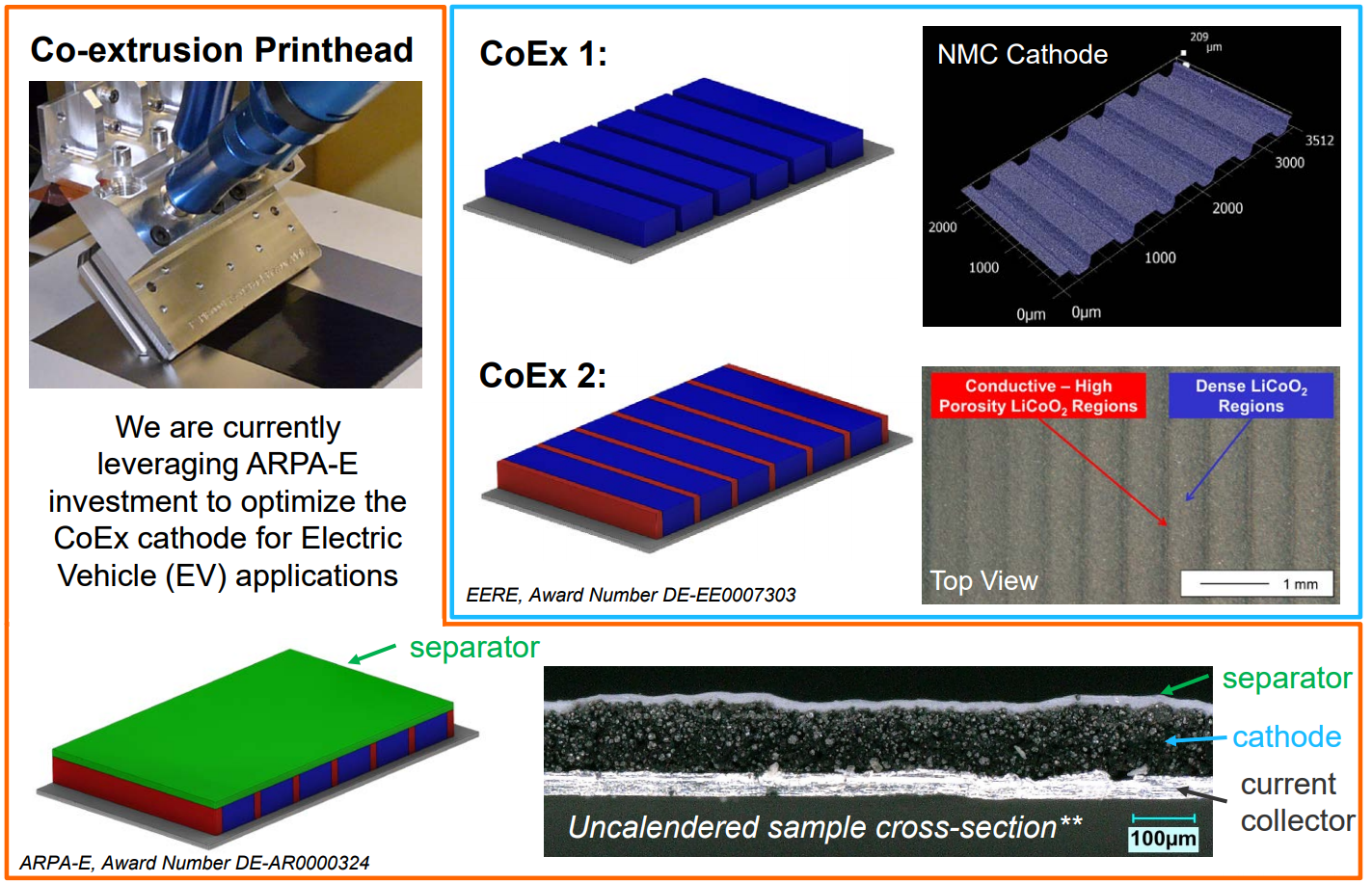

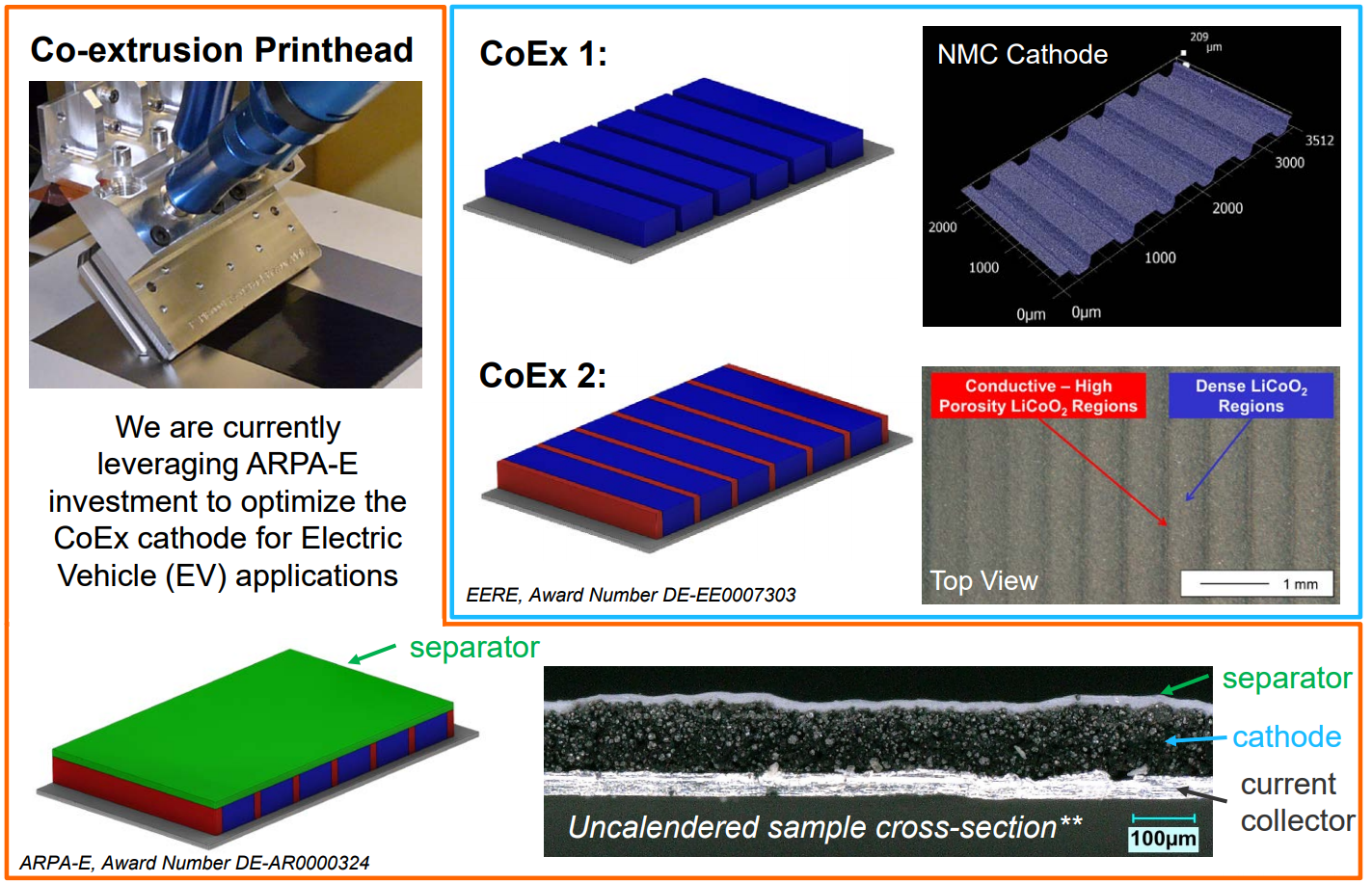

| Cobb, Corie Lynn Co-Extrusion: Advanced Manufacturing for Energy Devices Miscellaneous 2016. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @misc{cobb_co-extrusion:_2016,The U.S. Department of Energy's Office of Scientific and Technical Information |

| Cobb, Corie L; Ho, Christine C Additive Manufacturing: Rethinking Battery Design Journal Article In: The Electrochemical Society Interface, vol. 25, no. 1, pp. 75-78, 2016, ISSN: 1064-8208, 1944-8783. Abstract | Links | Tags: additive manufacturing, printed batteries @article{cobb_additive_2016,This article outlines emerging trends in the use of additive manufacturing techniques for the manufacture of batteries with customized geometries. Following a brief overview of conventional battery manufacturing, we discuss additive manufacturing strategies such as extrusion and dispenser printing, ink-jet printing, and screen printing in the context of battery manufacturing, and highlight the pros and cons of each technique. We provide some examples of 2D and 3D battery structures created by additive manufacturing, and highlight current and future research directions for battery design, manufacturing, and integration for small, portable and wearable electronics. |

| Cobb, Corie Lynn Co-extrusion print head for multi-layer battery structures Patent US9337471 B2, 2016. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_co-extrusion_2016,A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate. |

2014 |

|

| Cobb, Corie Lynn Co-extrusion print head for multi-layer battery structures Patent US20140186519A1, 2014. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{cobb_co-extrusion_2014,A co-extrusion print head capable of extruding at least two layers vertically in a single pass having a first inlet port connected to a first manifold, a first series of channels connected to the first inlet port arranged to receive a first fluid from the first inlet port, a second inlet port connected to one of either a second manifold or the first manifold, a second series of channels connected to the second inlet port arranged to receive a second fluid from the second inlet port, a merge portion of the print head connected to the first and second series of channels, the merge portion arranged to receive the first and second fluids, and an outlet port connected to the merge portion, the outlet port arranged to deposit the first and second fluids from the merge portion as a vertical stack on a substrate. |

| Bae, Chang-Jun; Shrader, Eric J; Cobb, Corie Lynn Advanced, high power and energy battery electrode manufactured by co-extrusion printing Patent US20140186700A1, 2014. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries @patent{bae_advanced_2014,A battery has an anode, a separator adjacent the anode, and a cathode adjacent the separator opposite the anode, the cathode comprising interdigitated stripes of materials, one of the materials forming a pore channel. |

2012 |

|

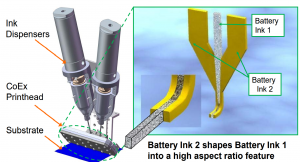

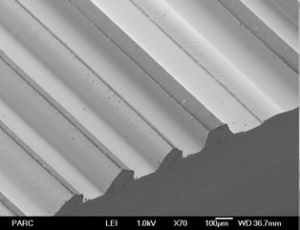

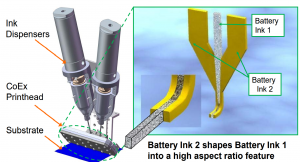

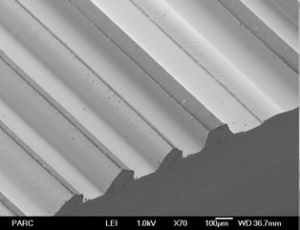

| Shrader, Eric J; Cobb, Corie L Co-Extrusion Printing for Low Cost and High Performance Energy Devices Proceedings Article In: Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy, pp. 537 – 540, NSTI, Santa Clara, CA, 2012, ISBN: 978-1-4665-6276-9. Abstract | Links | Tags: additive manufacturing, Co-extrusion, printed batteries, solar @inproceedings{shrader_co-extrusion_2012,The method of co-extrusion of dissimilar materials has been developed at the PARC, a Xerox Company, to successfully produce high aspect ratio structures for solar cell gridlines. In the solar application, the process is stable and repeatable, and a fully integrated tool has been developed that is now being demonstrated at a customer site. The co-extrusion process is capable of non-contact, direct deposition of features as small as 1 – 10 um with aspect ratios in the range of 1:1 to 30:1. Alternating fluids are co-extruded to form a fine vertically interdigitated lamina structure. The relative thickness, width, and length of the deposited features can be varied by altering the printhead geometry and printing process conditions. |

2011 |

|

| Littau, Karl A; Cobb, Corie L; Spengler, Nils; Solberg, Scott; Weisberg, Michael; Chang, Norinne; Rodkin, Alexandra Developments in MEMS scale printable alkaline and Li-ion technology Proceedings Article In: Micro- and Nanotechnology Sensors, Systems, and Applications III, pp. 80311L, International Society for Optics and Photonics, 2011. Abstract | Links | Tags: additive manufacturing, Co-extrusion, MEMS, printed batteries @inproceedings{littau_developments_2011,Two technologies for MEMS (Microelectromechanical Systems) scale cell formation are discussed. First, the fabrication of planar alkaline cell batteries compatible with MEMS scale power storage applications is shown. Both mm scale and sub-mm scale individual cells and batteries have been constructed. The chosen coplanar electrode geometry allows for easy fabrication of series connected cells enabling higher voltage while simplifying the cell sealing and electrode formation. The Zn/Ag alkaline system is used due to the large operating voltage, inherent charge capacity, long shelf life, and ease of fabrication. Several cells have been constructed using both plated and spun-on silver. The plated cells are shown to be limited in performance due to inadequate surface area and porosity; however, the cells made from spun-on colloidal silver show reasonable charge capacity and power performance with current densities of up to 200 uA/mm$^textrm2$ and charge capacities of up to 18 mA-s/mm$^textrm2$. Second, a new printing method for interdigitated 3-D cells is introduced. A microfluidic printhead capable of dispensing multiple materials at high resolution and aspect ratio is described and used to form fine interdigitated cell features which show >10 times improvement in energy density. Representative structures enabled by this method are modeled, and the energy and power density improvements are reported. |

2025 |

|

| Jitterbug: A Hybrid Digital Fabrication Platform for Rapid Prototyping of Printed Electronics Proceedings Article In: ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASME, 2025. |

| In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. |

2024 |

|

| High-Viscosity Phase Inversion Separators for Freestanding and Direct-on-Electrode Manufacturing in Lithium-Ion Batteries Journal Article In: ACS Applied Materials & Interfaces, vol. 16, no. 34, pp. 44863–44878, 2024, ISSN: 1944-8244, (Publisher: American Chemical Society). |

2023 |

|

| Engineering advanced Lithium-ion batteries with additive manufacturing Book Chapter In: Li, Jianlin; Jin, Congrui (Ed.): Processing and Manufacturing of Electrodes for Lithium-Ion Batteries, pp. 129–168, IET Digital Library, 2023, ISBN: 9781839536694. |

2021 |

|

| Modeling Current Density Non-Uniformities to Understand High-Rate Limitations in 3D Interdigitated Lithium-ion Batteries Journal Article In: Journal of The Electrochemical Society, vol. 168, no. 10, pp. 100512, 2021, ISSN: 1945-7111, (Publisher: The Electrochemical Society). |

| Modeling meso- and microstructure in materials patterned with acoustic focusing Journal Article In: Materials & Design, pp. 109512, 2021, ISSN: 0264-1275. |

2018 |

|

| Structures for interdigitated finger co-extrusion Patent US9899669B2, 2018. |

| Integral vasculature Patent US9884437B2, 2018. |

| Co-extrusion print head with edge bead reduction Patent US9855578B2, 2018. |

2017 |

|

| Co-extruded conformal battery separator and electrode Patent US9755221B2, 2017. |

| Structural designs for stretchable, conformal electrical interconnects Patent US20170215284A1, 2017. |

| Three dimensional co-extruded battery electrodes Patent US9590232B2, 2017. |

| US9543495B2, 2017. |

| Three dimensional co-extruded battery electrodes Patent US9793537B2, 2017. |

2016 |

|

| Co-Extrusion: Advanced Manufacturing for Energy Devices Miscellaneous 2016. |

| Additive Manufacturing: Rethinking Battery Design Journal Article In: The Electrochemical Society Interface, vol. 25, no. 1, pp. 75-78, 2016, ISSN: 1064-8208, 1944-8783. |

| Co-extrusion print head for multi-layer battery structures Patent US9337471 B2, 2016. |

2014 |

|

| Co-extrusion print head for multi-layer battery structures Patent US20140186519A1, 2014. |

| Advanced, high power and energy battery electrode manufactured by co-extrusion printing Patent US20140186700A1, 2014. |

2012 |

|

| Co-Extrusion Printing for Low Cost and High Performance Energy Devices Proceedings Article In: Nanotechnology 2012: Bio Sensors, Instruments, Medical, Environment and Energy, pp. 537 – 540, NSTI, Santa Clara, CA, 2012, ISBN: 978-1-4665-6276-9. |

2011 |

|

| Developments in MEMS scale printable alkaline and Li-ion technology Proceedings Article In: Micro- and Nanotechnology Sensors, Systems, and Applications III, pp. 80311L, International Society for Optics and Photonics, 2011. |