2025

|

| Hung, Chih-Hsuan; Allu, Srikanth; Cobb, Corie L. Computational Analysis of Anode and Cathode Structuring Effects on Charge and Discharge in GraphitetextbarLiNi0.6Mn0.2Co0.2O2 Batteries Journal Article Forthcoming In: Journal of The Electrochemical Society, Forthcoming, ISSN: 1945-7111. @article{hung_computational_2025b,

title = {Computational Analysis of Anode and Cathode Structuring Effects on Charge and Discharge in GraphitetextbarLiNi0.6Mn0.2Co0.2O2 Batteries},

author = {Chih-Hsuan Hung and Srikanth Allu and Corie L. Cobb},

url = {http://iopscience.iop.org/article/10.1149/1945-7111/ae0071},

doi = {10.1149/1945-7111/ae0071},

issn = {1945-7111},

year = {2025},

date = {2025-08-28},

urldate = {2025-08-28},

journal = {Journal of The Electrochemical Society},

abstract = {Structured electrodes (SEs) improve the rate capability of Lithium-ion batteries by engineering micrometer-scale electrolyte regions into the electrode, promoting rapid ionic transport. Prior research has focused on structuring one electrode (anode or cathode) with an analysis on either the charge or discharge performance. We present a holistic study using three-dimensional models to investigate the isolated effects of structuring either electrode and the combined effects of structuring both electrodes on the charge and discharge capacity of single-layer cells at 4C and 6C. Volumetric and gravimetric discharge energy density (Wh/Lstack and Wh/kgstack) and charge capacity (Ah/kgstack and Ah/Lstack) are evaluated for multi-layer pouch cell stacks. Pairing SE anodes with SE cathodes demonstrated improvements up to 15% in discharge Wh/kgstack and up to 33% in charge Ah/kgstack over a conventional cell; Energy required to charge per Ah/kgstack was improved by 13% –14%. SE cathodes paired with a conventional anode exhibited improvements of 0.3% – 22% across all performance metrics evaluated. Conversely, pairing a SE anode with a conventional cathode demonstrated improved charge capacity up to 13% but showed a 2% – 23% lower discharge energy density. The importance of aligning SEs in a cell from a performance and manufacturing perspective is also analyzed.},

keywords = {architected materials, battery modeling},

pubstate = {forthcoming},

tppubtype = {article}

}

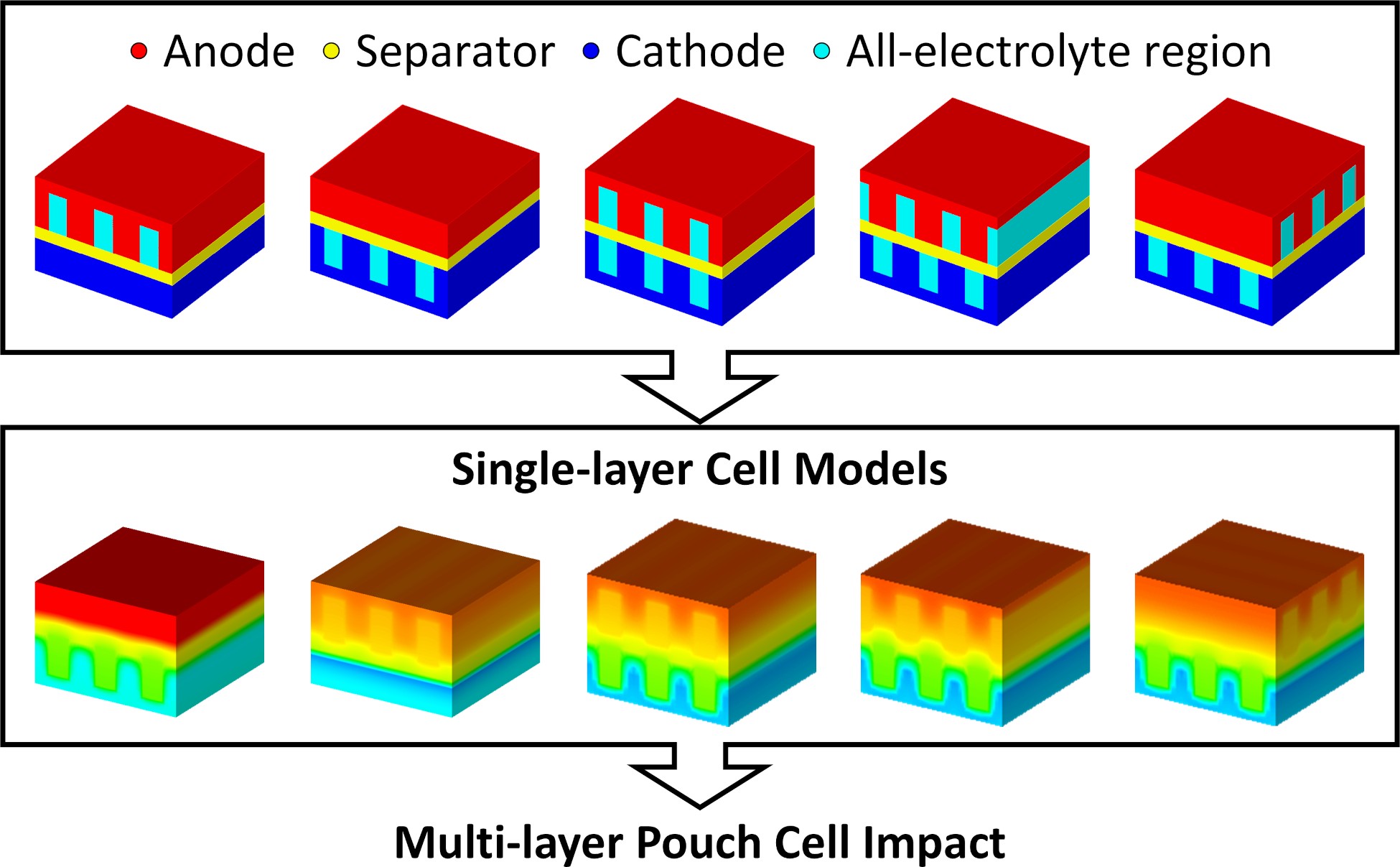

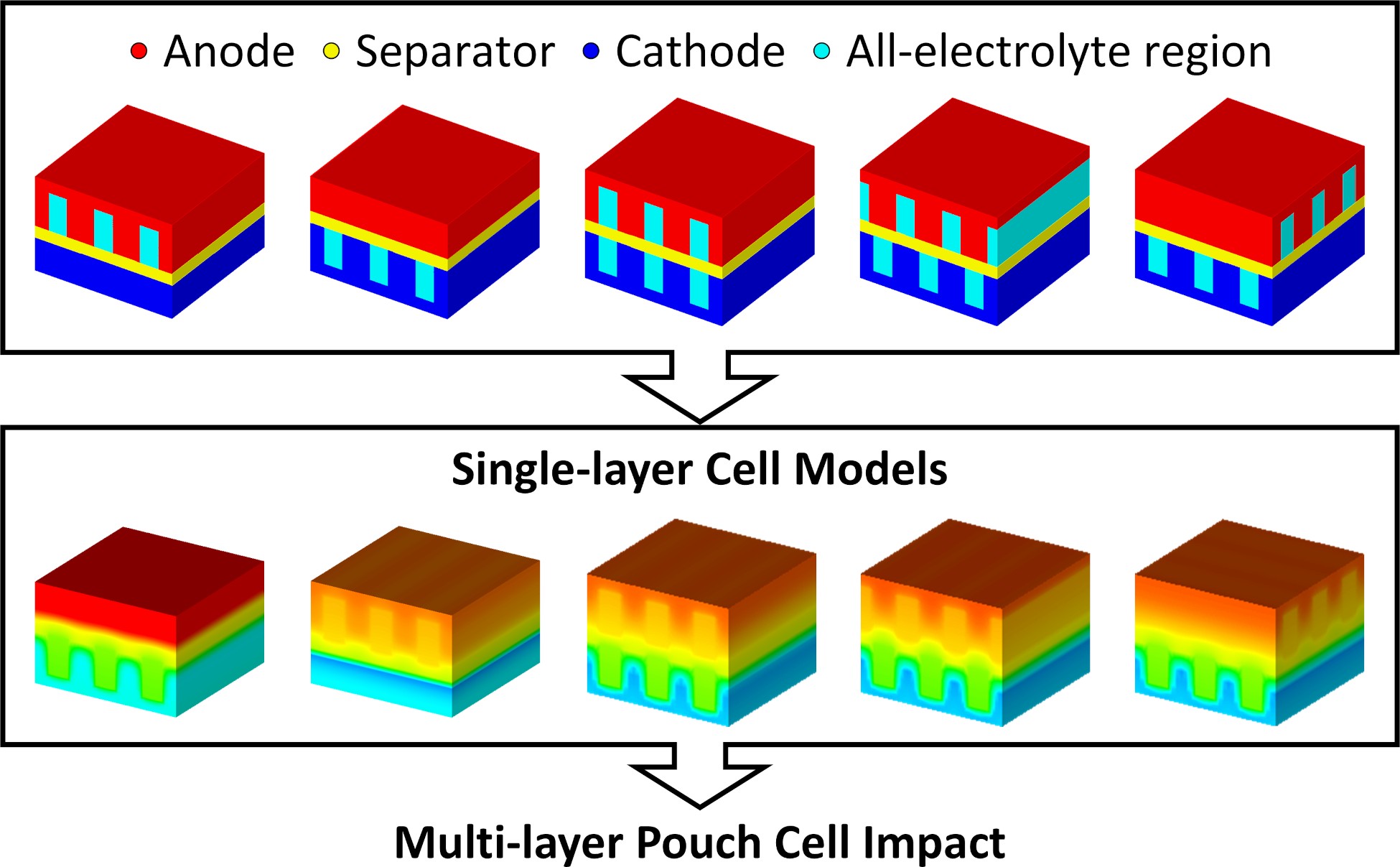

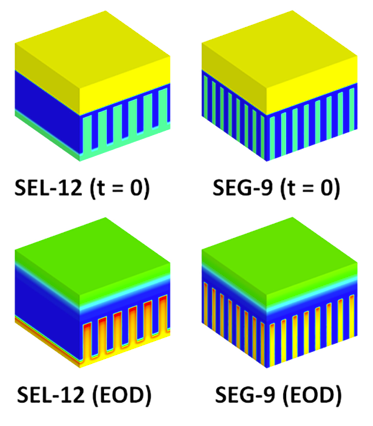

Structured electrodes (SEs) improve the rate capability of Lithium-ion batteries by engineering micrometer-scale electrolyte regions into the electrode, promoting rapid ionic transport. Prior research has focused on structuring one electrode (anode or cathode) with an analysis on either the charge or discharge performance. We present a holistic study using three-dimensional models to investigate the isolated effects of structuring either electrode and the combined effects of structuring both electrodes on the charge and discharge capacity of single-layer cells at 4C and 6C. Volumetric and gravimetric discharge energy density (Wh/Lstack and Wh/kgstack) and charge capacity (Ah/kgstack and Ah/Lstack) are evaluated for multi-layer pouch cell stacks. Pairing SE anodes with SE cathodes demonstrated improvements up to 15% in discharge Wh/kgstack and up to 33% in charge Ah/kgstack over a conventional cell; Energy required to charge per Ah/kgstack was improved by 13% –14%. SE cathodes paired with a conventional anode exhibited improvements of 0.3% – 22% across all performance metrics evaluated. Conversely, pairing a SE anode with a conventional cathode demonstrated improved charge capacity up to 13% but showed a 2% – 23% lower discharge energy density. The importance of aligning SEs in a cell from a performance and manufacturing perspective is also analyzed. |

| Hung, Chih-Hsuan; Allu, Srikanth; Cobb, Corie L. Modeling Structured Electrodes and Graded Porosity for Improving Discharge Rate Capability in Ultra-Thick Graphite|LiNi0.6Mn0.2Co0.2O2 Batteries Journal Article In: Journal of The Electrochemical Society, vol. 172, no. 1, pp. 010513, 2025, ISSN: 1945-7111, (Publisher: IOP Publishing). @article{hung_modeling_2025,

title = {Modeling Structured Electrodes and Graded Porosity for Improving Discharge Rate Capability in Ultra-Thick Graphite|LiNi0.6Mn0.2Co0.2O2 Batteries},

author = {Chih-Hsuan Hung and Srikanth Allu and Corie L. Cobb},

url = {https://dx.doi.org/10.1149/1945-7111/ada4e0},

doi = {10.1149/1945-7111/ada4e0},

issn = {1945-7111},

year = {2025},

date = {2025-01-01},

urldate = {2025-01-01},

journal = {Journal of The Electrochemical Society},

volume = {172},

number = {1},

pages = {010513},

abstract = {Long-range electric vehicles (EVs) require high-energy-density batteries that also meet the power demands of high current charge and discharge. Ultra-thick (>100 μm) Lithium-ion battery electrodes are critical to enable this need, but slow ion transport in conventional uniform electrodes (UEs) reduces battery capacity at increasing charge/discharge rates. We present a 3D computational analysis on the impact of structured electrode (SE) and graded electrode (GE) geometries on the discharge rate capability of ultra-thick graphitetextbarLiNi0.6Mn0.2Co0.2O2 (NMC-622) battery cells based on the footprint of a commercial EV pouch cell. SE cathodes with either a “grid” or “line” geometry and GEs with two layers of porosity were modeled. Based on the results of 230 models, we found that the electrolyte volume fraction is a key parameter that impacts capacity improvements in UEs, GEs, and SEs at 2 C–6 C discharge rates. SEs have the greatest discharge rate capability, outperforming GEs and UEs due to reduced Lithium-ion concentration gradients across the electrode thickness, which mitigates electrolyte depletion at high rates. The best SE model has a “grid” geometry with gravimetric and volumetric energy density improvements of 0.9%–4% at C/2–2 C and 18%–24% at 4 C–6 C relative to UEs.},

note = {Publisher: IOP Publishing},

keywords = {batteries, battery modeling},

pubstate = {published},

tppubtype = {article}

}

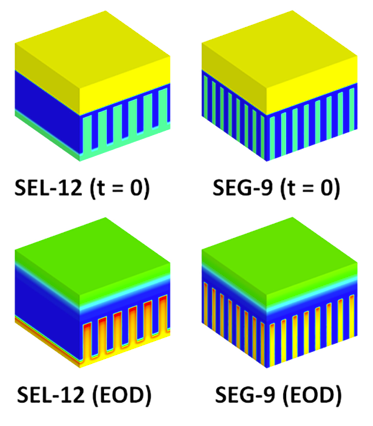

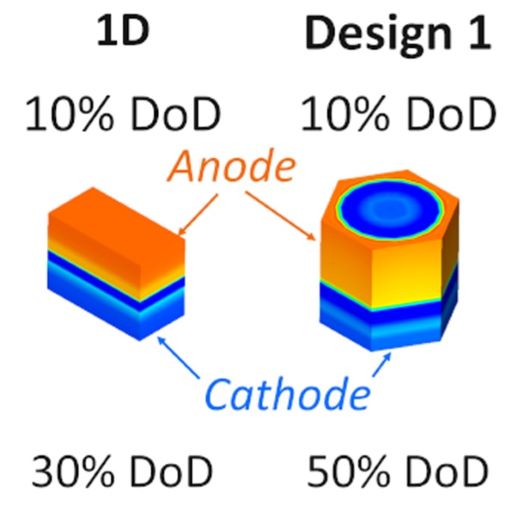

Long-range electric vehicles (EVs) require high-energy-density batteries that also meet the power demands of high current charge and discharge. Ultra-thick (>100 μm) Lithium-ion battery electrodes are critical to enable this need, but slow ion transport in conventional uniform electrodes (UEs) reduces battery capacity at increasing charge/discharge rates. We present a 3D computational analysis on the impact of structured electrode (SE) and graded electrode (GE) geometries on the discharge rate capability of ultra-thick graphitetextbarLiNi0.6Mn0.2Co0.2O2 (NMC-622) battery cells based on the footprint of a commercial EV pouch cell. SE cathodes with either a “grid” or “line” geometry and GEs with two layers of porosity were modeled. Based on the results of 230 models, we found that the electrolyte volume fraction is a key parameter that impacts capacity improvements in UEs, GEs, and SEs at 2 C–6 C discharge rates. SEs have the greatest discharge rate capability, outperforming GEs and UEs due to reduced Lithium-ion concentration gradients across the electrode thickness, which mitigates electrolyte depletion at high rates. The best SE model has a “grid” geometry with gravimetric and volumetric energy density improvements of 0.9%–4% at C/2–2 C and 18%–24% at 4 C–6 C relative to UEs. |

2021

|

| Hung, Chih-Hsuan; Allu, Srikanth; Cobb, Corie L Modeling Current Density Non-Uniformities to Understand High-Rate Limitations in 3D Interdigitated Lithium-ion Batteries Journal Article In: Journal of The Electrochemical Society, vol. 168, no. 10, pp. 100512, 2021, ISSN: 1945-7111, (Publisher: The Electrochemical Society). @article{hung_modeling_2021,

title = {Modeling Current Density Non-Uniformities to Understand High-Rate Limitations in 3D Interdigitated Lithium-ion Batteries},

author = {Chih-Hsuan Hung and Srikanth Allu and Corie L Cobb},

url = {https://doi.org/10.1149/1945-7111/ac2ac5},

doi = {10.1149/1945-7111/ac2ac5},

issn = {1945-7111},

year = {2021},

date = {2021-10-08},

urldate = {2021-10-08},

journal = {Journal of The Electrochemical Society},

volume = {168},

number = {10},

pages = {100512},

abstract = {Conventional planar Lithium-ion battery (LIB) cells are composed of a cathode and an anode with a polymer separator sheet sandwiched in between. Three-dimensional (3D) interdigitated batteries, where an anode and a cathode are intertwined, have been proposed as an alternative to planar LIBs to significantly improve energy, power, and fast charge performance. Various 3D battery designs have been demonstrated by researchers over the years, but a systematic study of how architecture and material impact 3D battery performance has been limited. In this paper, we conduct a comparative 3D computational modeling study on four 3D interdigitated battery designs previously shown in literature. We model each 3D battery using Li4Ti5O12 (LTO)∣LiFePO4 (LFP) and Graphite∣LiNi0.5Mn0.3Co0.2O2 (NMC), two widely studied LIB material systems, while conserving mass across all designs. Moreover, we propose a 3D current density metric to evaluate 3D LIBs and quantify the impact of current non-uniformities on high-rate LIB performance. Our results indicate that material selection and 3D architecture are equally critical for maximizing performance at high discharge rates. In addition, our analysis suggests quantifying the rate of change in current density early in a model discharge cycle can be a guiding metric to screen designs more quickly for premature failure.},

note = {Publisher: The Electrochemical Society},

keywords = {additive manufacturing, battery modeling},

pubstate = {published},

tppubtype = {article}

}

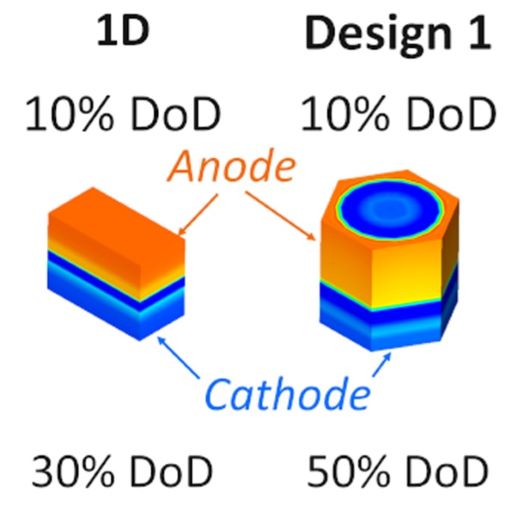

Conventional planar Lithium-ion battery (LIB) cells are composed of a cathode and an anode with a polymer separator sheet sandwiched in between. Three-dimensional (3D) interdigitated batteries, where an anode and a cathode are intertwined, have been proposed as an alternative to planar LIBs to significantly improve energy, power, and fast charge performance. Various 3D battery designs have been demonstrated by researchers over the years, but a systematic study of how architecture and material impact 3D battery performance has been limited. In this paper, we conduct a comparative 3D computational modeling study on four 3D interdigitated battery designs previously shown in literature. We model each 3D battery using Li4Ti5O12 (LTO)∣LiFePO4 (LFP) and Graphite∣LiNi0.5Mn0.3Co0.2O2 (NMC), two widely studied LIB material systems, while conserving mass across all designs. Moreover, we propose a 3D current density metric to evaluate 3D LIBs and quantify the impact of current non-uniformities on high-rate LIB performance. Our results indicate that material selection and 3D architecture are equally critical for maximizing performance at high discharge rates. In addition, our analysis suggests quantifying the rate of change in current density early in a model discharge cycle can be a guiding metric to screen designs more quickly for premature failure. |

2014

|

| Cobb, Corie L; Blanco, Mario Modeling mass and density distribution effects on the performance of co-extruded electrodes for high energy density lithium-ion batteries Journal Article In: Journal of Power Sources, vol. 249, pp. 357–366, 2014, ISSN: 0378-7753. @article{cobb_modeling_2014,

title = {Modeling mass and density distribution effects on the performance of co-extruded electrodes for high energy density lithium-ion batteries},

author = {Corie L Cobb and Mario Blanco},

url = {http://www.sciencedirect.com/science/article/pii/S0378775313017503},

doi = {10.1016/j.jpowsour.2013.10.084},

issn = {0378-7753},

year = {2014},

date = {2014-01-01},

urldate = {2017-09-13},

journal = {Journal of Power Sources},

volume = {249},

pages = {357--366},

abstract = {Utilizing an existing macro-homogeneous porous electrode model developed by John Newman, this paper aims to explore the potential energy density gains which can be realized in lithium-ion battery electrodes fabricated with co-extrusion printing technology. This paper conducts an analysis on two-dimensional electrode cross-sections and presents the electrochemical performance results, including calculated volumetric energy capacity for a general class of lithium cobalt oxide (LiCoO2) co-extruded cathodes, in the presence of a lithium metal anode, polymer separator and liquid ethylene carbonate, propylene carbonate, and dimethyl carbonate (EC:PC:DMC) electrolyte. The impact of structured electrodes on cell performance is investigated by varying the physical distribution of a fixed amount of cathode mass over a space of dimensions which can be fabricated by co-extrusion. By systematically varying the thickness and aspect ratio of the electrode structures, we present an optimal subset of geometries and design rules for co-extruded geometries. Modeling results demonstrate that ultra-thick LiCoO2 electrodes, on the order of 150–300 μm, can garner a substantial improvement in material utilization and in turn capacity through electrolyte channels and fine width electrode pillars which are 25–100 μm wide.},

keywords = {battery modeling, Co-extrusion, printed batteries},

pubstate = {published},

tppubtype = {article}

}

Utilizing an existing macro-homogeneous porous electrode model developed by John Newman, this paper aims to explore the potential energy density gains which can be realized in lithium-ion battery electrodes fabricated with co-extrusion printing technology. This paper conducts an analysis on two-dimensional electrode cross-sections and presents the electrochemical performance results, including calculated volumetric energy capacity for a general class of lithium cobalt oxide (LiCoO2) co-extruded cathodes, in the presence of a lithium metal anode, polymer separator and liquid ethylene carbonate, propylene carbonate, and dimethyl carbonate (EC:PC:DMC) electrolyte. The impact of structured electrodes on cell performance is investigated by varying the physical distribution of a fixed amount of cathode mass over a space of dimensions which can be fabricated by co-extrusion. By systematically varying the thickness and aspect ratio of the electrode structures, we present an optimal subset of geometries and design rules for co-extruded geometries. Modeling results demonstrate that ultra-thick LiCoO2 electrodes, on the order of 150–300 μm, can garner a substantial improvement in material utilization and in turn capacity through electrolyte channels and fine width electrode pillars which are 25–100 μm wide. |

| Cobb, Corie Lynn; Bae, Chang-Jun Tortuosity of Binder-Free and Carbon-Free High Energy Density LiCoO2 Electrodes for Rechargeable Lithium-Ion Batteries Proceedings Article In: ECS Transactions, pp. 13–24, The Electrochemical Society, 2014. @inproceedings{cobb_tortuosity_2014,

title = {Tortuosity of Binder-Free and Carbon-Free High Energy Density LiCoO2 Electrodes for Rechargeable Lithium-Ion Batteries},

author = {Corie Lynn Cobb and Chang-Jun Bae},

url = {https://iopscience.iop.org/article/10.1149/05813.0013ecst},

doi = {10.1149/05813.0013ecst},

year = {2014},

date = {2014-01-01},

urldate = {2018-03-05},

booktitle = {ECS Transactions},

volume = {58},

pages = {13--24},

publisher = {The Electrochemical Society},

abstract = {Conventional electrodes, by volume, contain a large amount of electrochemically inactive material such as binder and carbon. This lowers the overall capacity of a battery and makes it difficult to realize high volumetric energy. Researchers have been actively pursuing methods which will enable the fabrication and full utilization of thick electrodes (≥200µm) with a minimal amount of inactive material. One approach which has emerged is to fabricate thick sintered electrode structures which are free of binder and carbon. However, these structures do not adhere to conventional assumptions about tortuosity. This paper aims to correlate John Newman’s macrohomogeneous porous electrode model to thick high energy density, carbon-free and binder-free sintered electrode samples fabricated at PARC. We examine how assumptions about tortuosity affect model predictions of capacity. Our efforts focus on understanding the model parameters which can be used in Newman’s existing model without modification to the underlying equations.},

keywords = {battery modeling},

pubstate = {published},

tppubtype = {inproceedings}

}

Conventional electrodes, by volume, contain a large amount of electrochemically inactive material such as binder and carbon. This lowers the overall capacity of a battery and makes it difficult to realize high volumetric energy. Researchers have been actively pursuing methods which will enable the fabrication and full utilization of thick electrodes (≥200µm) with a minimal amount of inactive material. One approach which has emerged is to fabricate thick sintered electrode structures which are free of binder and carbon. However, these structures do not adhere to conventional assumptions about tortuosity. This paper aims to correlate John Newman’s macrohomogeneous porous electrode model to thick high energy density, carbon-free and binder-free sintered electrode samples fabricated at PARC. We examine how assumptions about tortuosity affect model predictions of capacity. Our efforts focus on understanding the model parameters which can be used in Newman’s existing model without modification to the underlying equations. |

0000

|

| Hung, Chih-Hsuan; Allu, Srikanth; Cobb, Corie L. Computational Analysis of Anode and Cathode Structuring Effects on Charge and Discharge in GraphitetextbarLiNi0.6Mn0.2Co0.2O2 Batteries Journal Article Forthcoming In: Journal of The Electrochemical Society, Forthcoming, ISSN: 1945-7111. @article{hung_computational_2025,

title = {Computational Analysis of Anode and Cathode Structuring Effects on Charge and Discharge in GraphitetextbarLiNi0.6Mn0.2Co0.2O2 Batteries},

author = {Chih-Hsuan Hung and Srikanth Allu and Corie L. Cobb},

url = {http://iopscience.iop.org/article/10.1149/1945-7111/ae0071},

doi = {10.1149/1945-7111/ae0071},

issn = {1945-7111},

journal = {Journal of The Electrochemical Society},

abstract = {Structured electrodes (SEs) improve the rate capability of Lithium-ion batteries by engineering micrometer-scale electrolyte regions into the electrode, promoting rapid ionic transport. Prior research has focused on structuring one electrode (anode or cathode) with an analysis on either the charge or discharge performance. We present a holistic study using three-dimensional models to investigate the isolated effects of structuring either electrode and the combined effects of structuring both electrodes on the charge and discharge capacity of single-layer cells at 4C and 6C. Volumetric and gravimetric discharge energy density (Wh/Lstack and Wh/kgstack) and charge capacity (Ah/kgstack and Ah/Lstack) are evaluated for multi-layer pouch cell stacks. Pairing SE anodes with SE cathodes demonstrated improvements up to 15% in discharge Wh/kgstack and up to 33% in charge Ah/kgstack over a conventional cell; Energy required to charge per Ah/kgstack was improved by 13% –14%. SE cathodes paired with a conventional anode exhibited improvements of 0.3% – 22% across all performance metrics evaluated. Conversely, pairing a SE anode with a conventional cathode demonstrated improved charge capacity up to 13% but showed a 2% – 23% lower discharge energy density. The importance of aligning SEs in a cell from a performance and manufacturing perspective is also analyzed.},

keywords = {architected materials, batteries, battery modeling},

pubstate = {forthcoming},

tppubtype = {article}

}

Structured electrodes (SEs) improve the rate capability of Lithium-ion batteries by engineering micrometer-scale electrolyte regions into the electrode, promoting rapid ionic transport. Prior research has focused on structuring one electrode (anode or cathode) with an analysis on either the charge or discharge performance. We present a holistic study using three-dimensional models to investigate the isolated effects of structuring either electrode and the combined effects of structuring both electrodes on the charge and discharge capacity of single-layer cells at 4C and 6C. Volumetric and gravimetric discharge energy density (Wh/Lstack and Wh/kgstack) and charge capacity (Ah/kgstack and Ah/Lstack) are evaluated for multi-layer pouch cell stacks. Pairing SE anodes with SE cathodes demonstrated improvements up to 15% in discharge Wh/kgstack and up to 33% in charge Ah/kgstack over a conventional cell; Energy required to charge per Ah/kgstack was improved by 13% –14%. SE cathodes paired with a conventional anode exhibited improvements of 0.3% – 22% across all performance metrics evaluated. Conversely, pairing a SE anode with a conventional cathode demonstrated improved charge capacity up to 13% but showed a 2% – 23% lower discharge energy density. The importance of aligning SEs in a cell from a performance and manufacturing perspective is also analyzed. |