2025 |

|

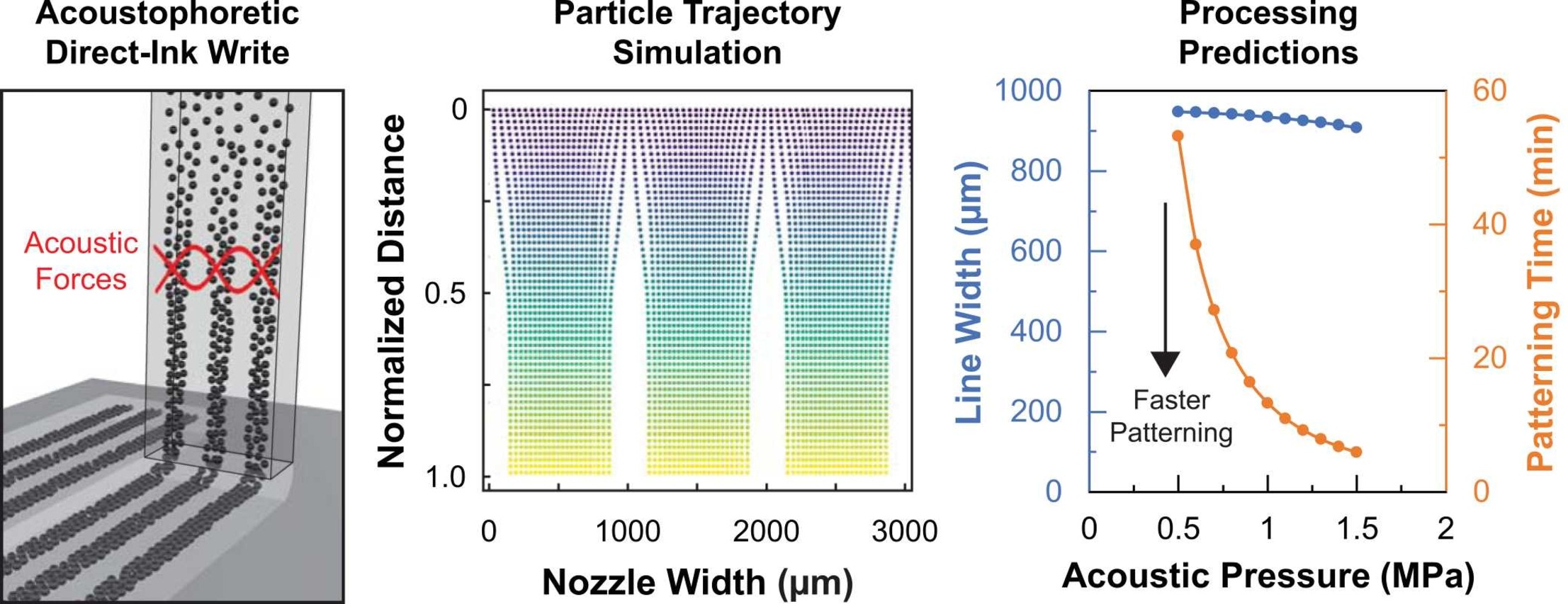

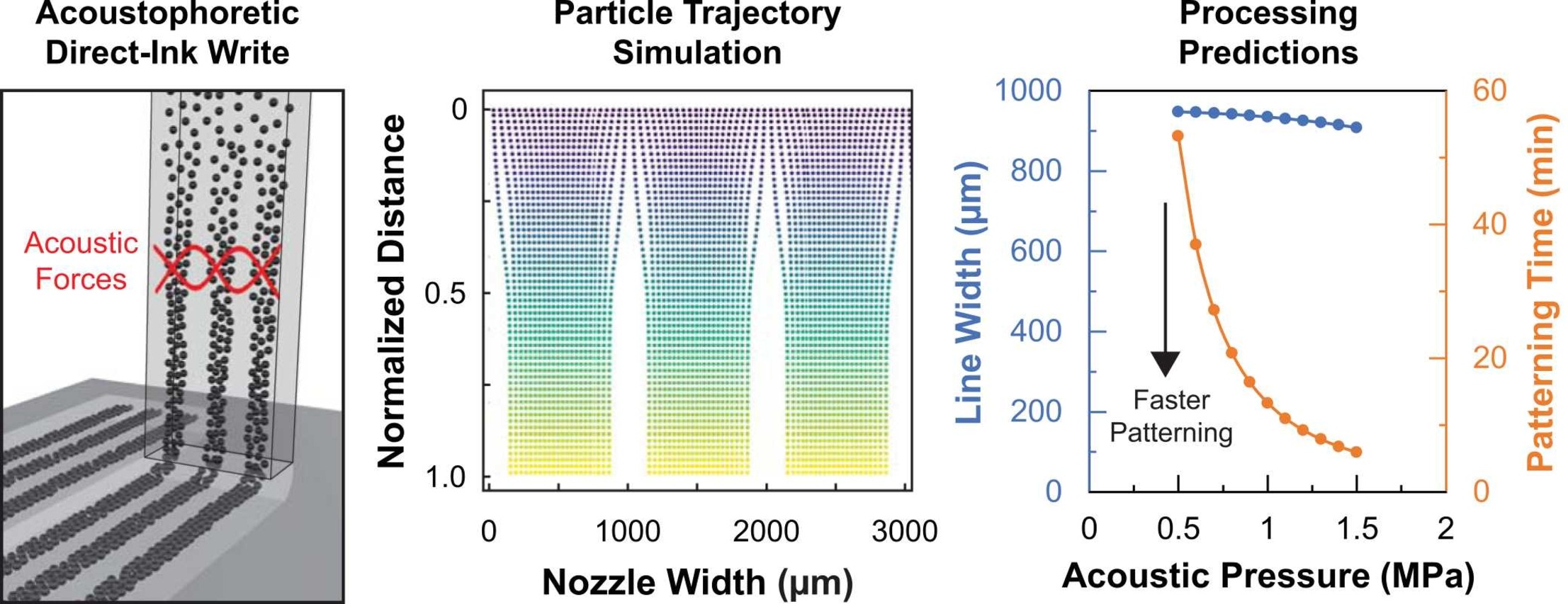

| Armstrong, Emilee N.; Johnson, Keith E.; Herbruger, Kyle A.; Sanchez, Austin K.; Begley, Matthew R.; Cobb, Corie L. In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. Abstract | Links | Tags: 3D printing, acoustic focusing, acoustophoresis, additive manufacturing @article{armstrong_predicting_2025,Patterned functional materials offer improved properties (electrical, thermal, etc.) over their bulk counterparts in many applications, including energy storage, flexible electronics, and sensors. However, manufacturing approaches for patterning materials over large areas with features on the order of hundreds of microns or less are limited. Acoustophoresis, which uses acoustic forces to control particle arrangement in a fluid medium, is a pathway to address this challenge. This process is dependent on particle and fluid properties and enables patterning of a broad range of materials. Herein, a model with experimental validation is presented to demonstrate that acoustophoresis can be combined with direct-ink writing (DIW) to fabricate line patterns over large cm-scale areas. An in-nozzle particle interaction model was developed to investigate the impact of processing conditions on multi-nodal acoustophoretic DIW. The model predicts patterned line widths within a factor of two relative to experimental results for a high viscosity case study. The model was used to investigate the impact of frequency, particle loading, particle radius, and acoustic pressure on line width and patterning time, providing critical feedback regarding the processing conditions suitable for a target application. Model results illustrate that frequency has the greatest impact on line patterns: increasing from 1 to 3MHz resulted in a greater than 65% reduction in line width and a greater than 85% reduction in patterning time. Additionally, experiments were conducted with an alumina-epoxy ink, and a textasciitilde21 cm2 area pattern was rastered in textasciitilde5.5minutes, demonstrating a path towards large-area line-patterned composite fabrication. |

2023 |

|

| Johnson, Keith E.; Montano, Brandon C.; Nambu, Kailino J.; Armstrong, Emilee N.; Cobb, Corie L.; Begley, Matthew R. Two-dimensional patterning of mesoscale fibers using acoustophoresis Journal Article In: Materials & Design, vol. 234, pp. 112328, 2023, ISSN: 0264-1275. Abstract | Links | Tags: acoustic focusing, acoustophoresis, periodic patterns @article{johnson_two-dimensional_2023,The performance of functional composites can rely critically on the arrangement of secondary phases; for example, patterned networks of conductive particles can impart anisotropic thermal, electric or ionic conductivity while preserving flexibility in the matrix. We demonstrate the use of standing acoustic waves to generate periodic patterns of short fibers. We extend the range of possible patterns with the first demonstration of both rectangular grids and arrays of octagons interspersed with rectangles. These newly demonstrated patterns are rationalized using theoretical models of acoustic forces and torques on fibers that account for two-dimensional spatial variations arising from applied acoustic fields. The models enable simulations of fiber motion, which are used to (i) map out final fiber positions as a function of initial position and orientation, and (ii) corroborate experiments visualizing fiber motion and final patterns. This approach provides a fast and accurate way to predict emergent fiber patterns as a function of excitation modality and fiber length. The theory and experiments clearly indicate strong coupling between the length of the fibers and the spacing of the acoustic nodes. This coupling is used to estimate reductions in percolation thresholds associated with the ratio of fiber length and acoustic wavelength. |

2022 |

|

| Melchert, Drew S.; Tahmasebipour, Amir; Liu, Xin; Mancini, Julie; Moran, Bryan; Giera, Brian; Joshipura, Ishan D.; Shusteff, Maxim; Meinhart, Carl D.; Cobb, Corie L.; Spadaccini, Christopher; Gianola, Daniel S.; Begley, Matthew R. Anisotropic Thermally Conductive Composites Enabled by Acoustophoresis and Stereolithography Journal Article In: Advanced Functional Materials, pp. 2201687, 2022, ISSN: 1616-3028. Abstract | Links | Tags: 3D printing, acoustophoresis, composites, stereolithography @article{melchert_anisotropic_nodate,Opportunities to improve thermal management in electronic devices are currently hindered by processing constraints that limit thermal conductivity in polymer-matrix composites. Active patterning of filler particles is a promising route to improve conductivity while retaining processability by improving particle contact density and directing heat along optimized pathways. This study employs acoustic patterning to align and compact filler particles into stripes during stereolithographic 3D printing. This approach produces polymer-based composite materials with highly efficient embedded heat transport pathways which reach 95 vol% particle utilization (relative to the parallel conduction upper limit). These composites exhibit anisotropic thermal conductivity up to 300% higher than unpatterned composites, with in-plane anisotropy ratios of up to 350%. Combining this high conductivity with 3D printing enables materials with engineered heat networks that optimize transport from hot spots to heatsinks while maintaining low viscosity for fast particle patterning and for infiltration around electronic components. Finally, numerical simulations of acoustic assembly of particles with varied geometry, when compared to experimentally characterized particle packing, illuminate pathways for further improving conductivity by optimizing particle geometry for alignment and stacking of particles with maximum contact surface area. |

2025 |

|

| In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. |

2023 |

|

| Two-dimensional patterning of mesoscale fibers using acoustophoresis Journal Article In: Materials & Design, vol. 234, pp. 112328, 2023, ISSN: 0264-1275. |

2022 |

|

| Anisotropic Thermally Conductive Composites Enabled by Acoustophoresis and Stereolithography Journal Article In: Advanced Functional Materials, pp. 2201687, 2022, ISSN: 1616-3028. |