2025 |

|

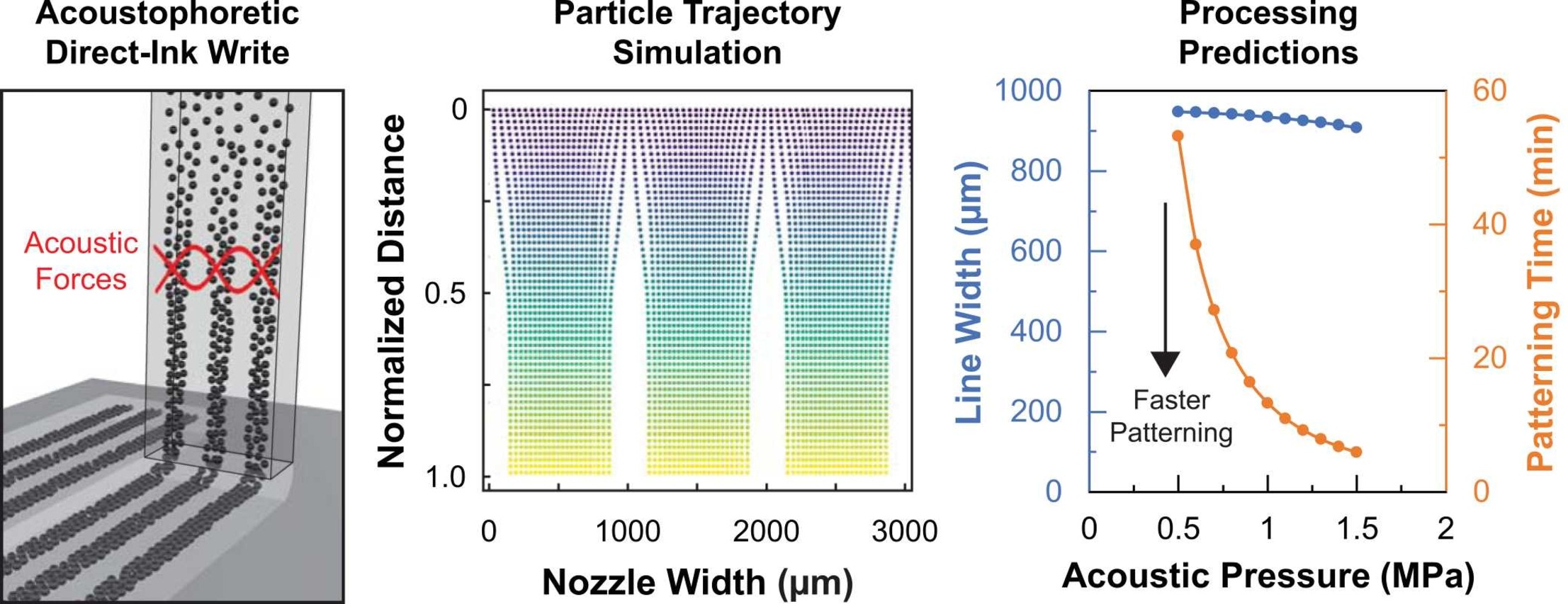

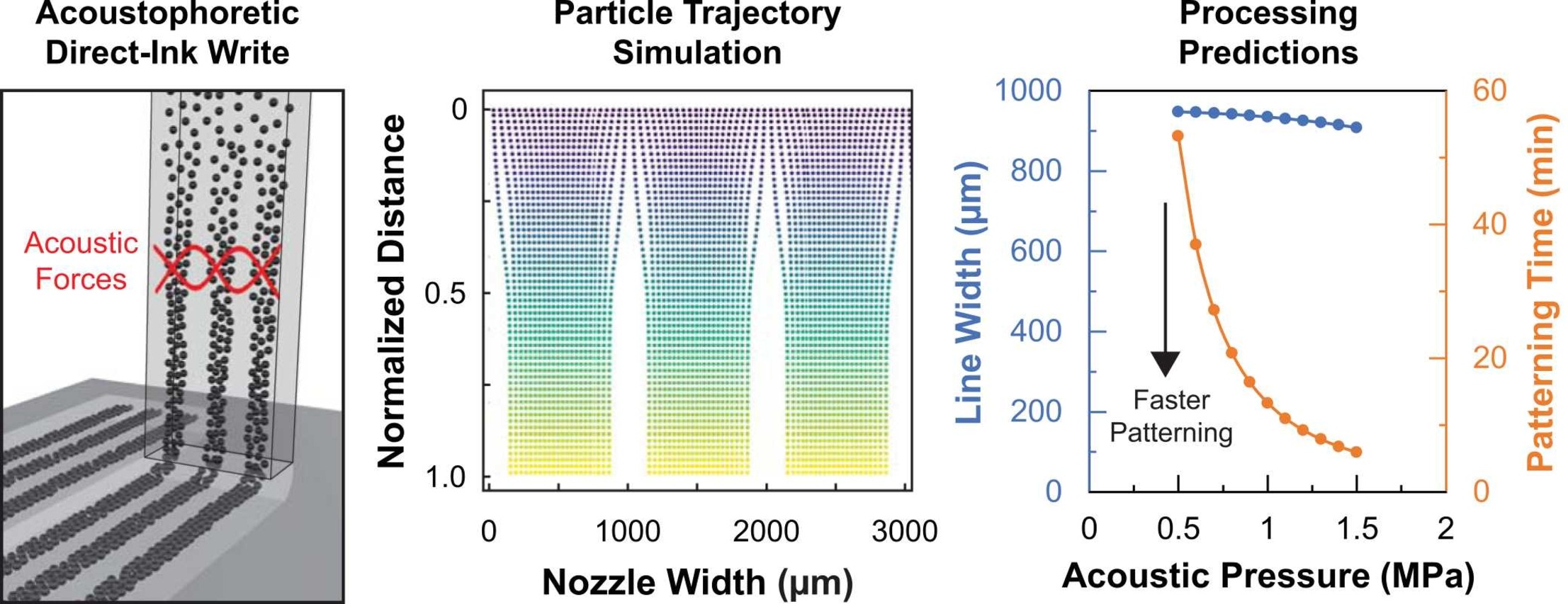

| Armstrong, Emilee N.; Johnson, Keith E.; Herbruger, Kyle A.; Sanchez, Austin K.; Begley, Matthew R.; Cobb, Corie L. In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. Abstract | Links | Tags: 3D printing, acoustic focusing, acoustophoresis, additive manufacturing @article{armstrong_predicting_2025,Patterned functional materials offer improved properties (electrical, thermal, etc.) over their bulk counterparts in many applications, including energy storage, flexible electronics, and sensors. However, manufacturing approaches for patterning materials over large areas with features on the order of hundreds of microns or less are limited. Acoustophoresis, which uses acoustic forces to control particle arrangement in a fluid medium, is a pathway to address this challenge. This process is dependent on particle and fluid properties and enables patterning of a broad range of materials. Herein, a model with experimental validation is presented to demonstrate that acoustophoresis can be combined with direct-ink writing (DIW) to fabricate line patterns over large cm-scale areas. An in-nozzle particle interaction model was developed to investigate the impact of processing conditions on multi-nodal acoustophoretic DIW. The model predicts patterned line widths within a factor of two relative to experimental results for a high viscosity case study. The model was used to investigate the impact of frequency, particle loading, particle radius, and acoustic pressure on line width and patterning time, providing critical feedback regarding the processing conditions suitable for a target application. Model results illustrate that frequency has the greatest impact on line patterns: increasing from 1 to 3MHz resulted in a greater than 65% reduction in line width and a greater than 85% reduction in patterning time. Additionally, experiments were conducted with an alumina-epoxy ink, and a textasciitilde21 cm2 area pattern was rastered in textasciitilde5.5minutes, demonstrating a path towards large-area line-patterned composite fabrication. |

2023 |

|

| Cobb, Corie L.; Katz, Michelle E. R. Engineering advanced Lithium-ion batteries with additive manufacturing Book Chapter In: Li, Jianlin; Jin, Congrui (Ed.): Processing and Manufacturing of Electrodes for Lithium-Ion Batteries, pp. 129–168, IET Digital Library, 2023, ISBN: 9781839536694. Abstract | Links | Tags: 3D printing, additive manufacturing, batteries @inbook{cobb_engineering_2023,Additive manufacturing (AM) enables the fabrication of complex shapes and formfactors that are inefficient or impossible to produce with traditional subtractive machining tools. AM emerged in the 1980s to enable the rapid creation of functional prototypes (also known as rapid prototyping). The first commercial implementation of AM was a stereolithography (SLA) system developed by 3D Systems in 1987, wherein a laser solidified thin layers of a photoactive polymer solution. In the early 1990s, fused deposition modeling (FDM), selective laser sintering, and other AM modalities began to emerge and have continued to grow in the decades since. Within the last ten years, AM has gained traction as an approach to fabricate Lithium-ion batteries (LIBs) because it enables (1) novel three-dimensional (3D) electrodes that optimize energy and power performance and (2) customizable battery shapes for integrated and mechanically robust batteries for portable device applications. As energy storage demands grow, so does the need for LIBs to come in a multitude of sizes, shapes, and materials that meet the needs of a given application. In this chapter, we review the main AM approaches that have been used to produce LIBs with a focus on FDM, direct-ink write (DIW), inkjet printing (IJP), aerosol jet printing (AJP), electrostatic spray deposition (ESD), stereolithography (SLA), and newer field-assisted (FA) methods. |

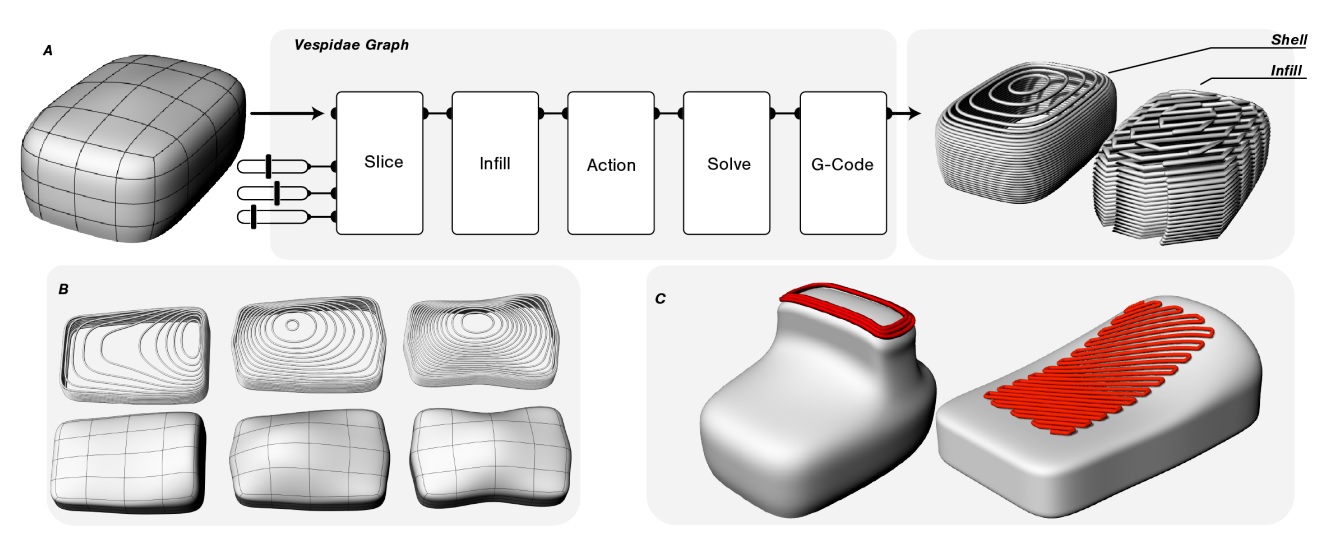

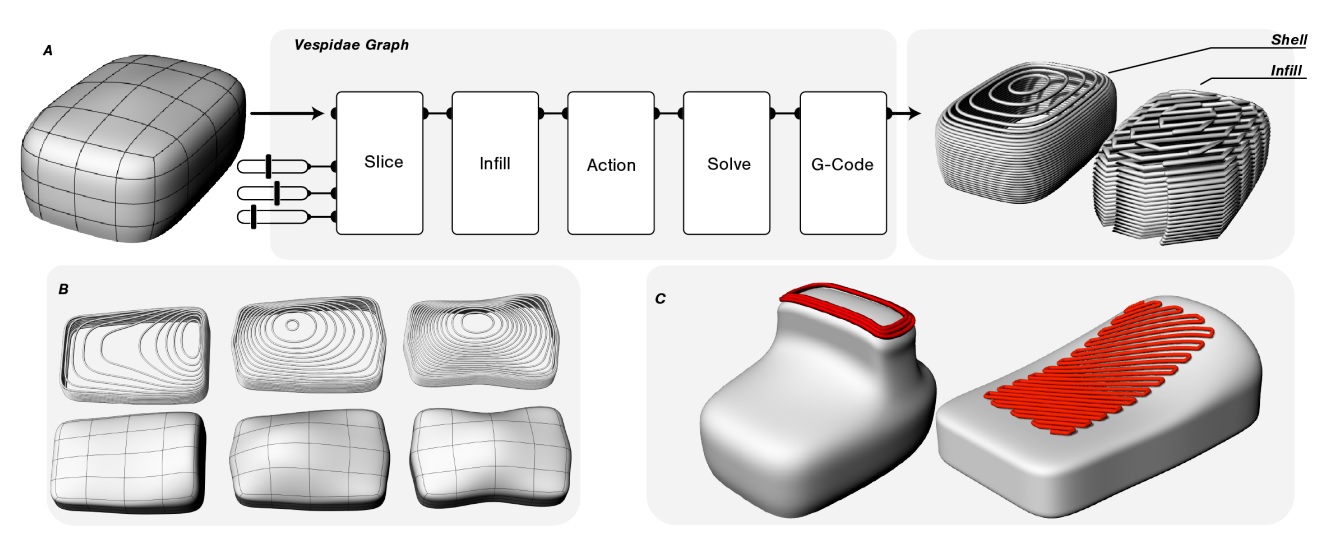

| Fossdal, Frikk H; Nguyen, Vinh; Heldal, Rogardt; Cobb, Corie L.; Peek, Nadya Vespidae: A Programming Framework for Developing Digital Fabrication Workflows Proceedings Article In: Proceedings of the 2023 ACM Designing Interactive Systems Conference, pp. 2034–2049, Association for Computing Machinery, New York, NY, USA, 2023, ISBN: 978-1-4503-9893-0. Abstract | Links | Tags: 3D printing, CAD/CAM, digital fabrication @inproceedings{fossdal_vespidae_2023,Digital fabrication machines are controlled through code. Software that generates this code, such as slicers, often rely on abstractions that restrict practitioners from exploring the full design space. We contribute Vespidae, a programming framework for developing custom toolpaths and visualizations. Vespidae module types include Toolpaths, Actions, Solvers, and Export. These generate geometry, specify machine tasks, sort and visualize action sequences, and generate and stream machine code. We show example workflows that demonstrate Vespidae’s strengths in supporting iteration and unconventional practice. These include non-planar 3D printing, varying a print’s tactile qualities with under-extrusion, and exploring the design space of milling marks. Furthermore, we used Vespidae over the course of six months to explore multi-material 3D printing for energy storage devices on a custom machine. Finally, we discuss how Vespidae contributes to a movement in HCI arguing for human-machine collaboration. |

2022 |

|

| Melchert, Drew S.; Tahmasebipour, Amir; Liu, Xin; Mancini, Julie; Moran, Bryan; Giera, Brian; Joshipura, Ishan D.; Shusteff, Maxim; Meinhart, Carl D.; Cobb, Corie L.; Spadaccini, Christopher; Gianola, Daniel S.; Begley, Matthew R. Anisotropic Thermally Conductive Composites Enabled by Acoustophoresis and Stereolithography Journal Article In: Advanced Functional Materials, pp. 2201687, 2022, ISSN: 1616-3028. Abstract | Links | Tags: 3D printing, acoustophoresis, composites, stereolithography @article{melchert_anisotropic_nodate,Opportunities to improve thermal management in electronic devices are currently hindered by processing constraints that limit thermal conductivity in polymer-matrix composites. Active patterning of filler particles is a promising route to improve conductivity while retaining processability by improving particle contact density and directing heat along optimized pathways. This study employs acoustic patterning to align and compact filler particles into stripes during stereolithographic 3D printing. This approach produces polymer-based composite materials with highly efficient embedded heat transport pathways which reach 95 vol% particle utilization (relative to the parallel conduction upper limit). These composites exhibit anisotropic thermal conductivity up to 300% higher than unpatterned composites, with in-plane anisotropy ratios of up to 350%. Combining this high conductivity with 3D printing enables materials with engineered heat networks that optimize transport from hot spots to heatsinks while maintaining low viscosity for fast particle patterning and for infiltration around electronic components. Finally, numerical simulations of acoustic assembly of particles with varied geometry, when compared to experimentally characterized particle packing, illuminate pathways for further improving conductivity by optimizing particle geometry for alignment and stacking of particles with maximum contact surface area. |

2025 |

|

| In: Additive Manufacturing, vol. 106, pp. 104778, 2025, ISSN: 2214-8604. |

2023 |

|

| Engineering advanced Lithium-ion batteries with additive manufacturing Book Chapter In: Li, Jianlin; Jin, Congrui (Ed.): Processing and Manufacturing of Electrodes for Lithium-Ion Batteries, pp. 129–168, IET Digital Library, 2023, ISBN: 9781839536694. |

| Vespidae: A Programming Framework for Developing Digital Fabrication Workflows Proceedings Article In: Proceedings of the 2023 ACM Designing Interactive Systems Conference, pp. 2034–2049, Association for Computing Machinery, New York, NY, USA, 2023, ISBN: 978-1-4503-9893-0. |

2022 |

|

| Anisotropic Thermally Conductive Composites Enabled by Acoustophoresis and Stereolithography Journal Article In: Advanced Functional Materials, pp. 2201687, 2022, ISSN: 1616-3028. |