The use of recycled asphalt pavement (RAP) is a sustainable practice that potentially could help reduce construction costs, preserve the environment, and reduce greenhouse gas emissions, provided that the engineering performance of the roadways constructed with RAP is not compromised. This project sought to determine the limits for using RAP as a roadway embankment material and to develop draft specifications for the required material and its placement.

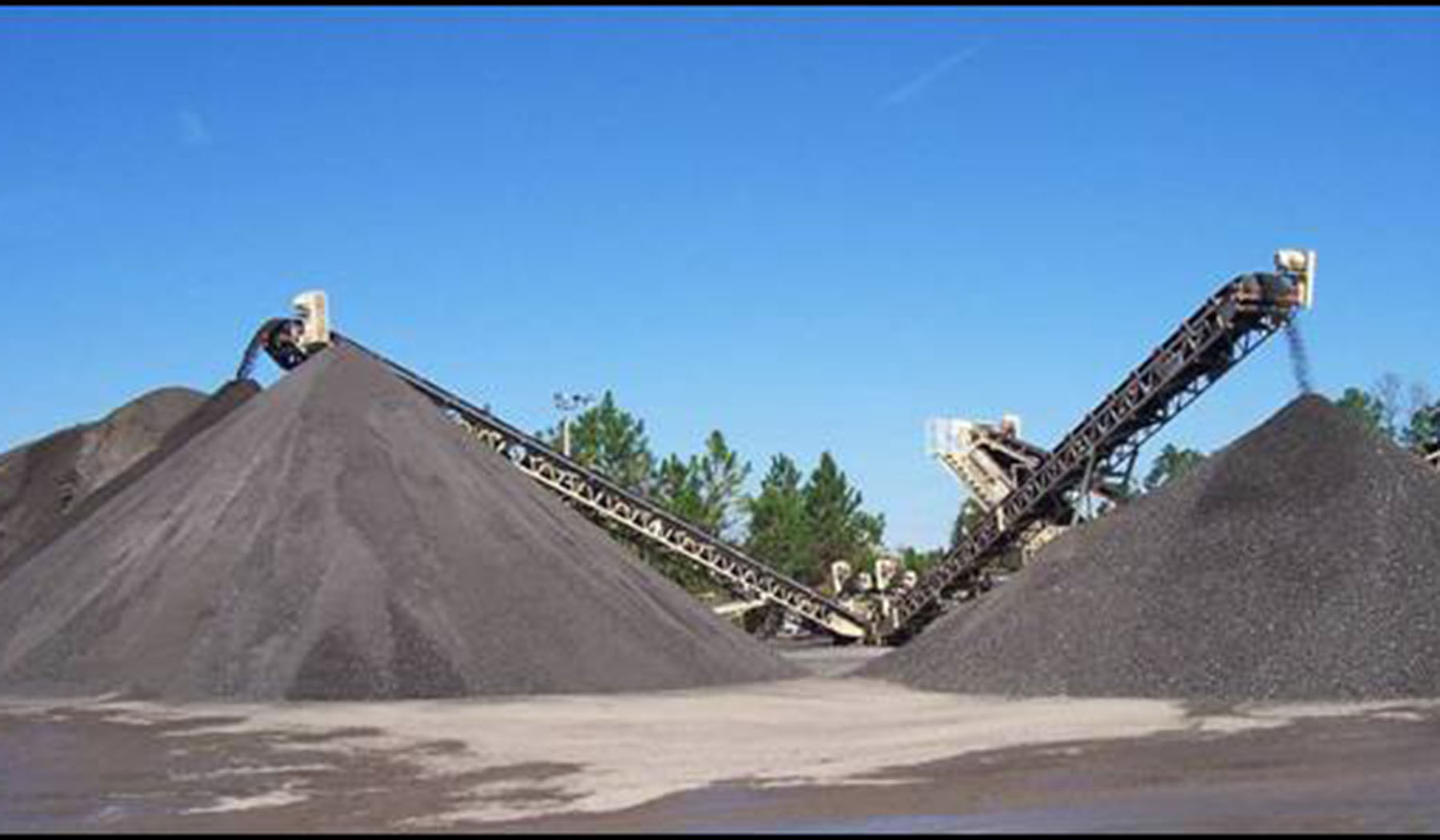

RAP refers to unprocessed (milled) or processed (screened) asphalt mixture obtained from roadways or other sources. Currently, the Illinois State Toll Highway Authority (Illinois Tollway) allows RAP to be used in roadway embankments and as structural backfill, as well as for aggregate surfacing, in accordance with Illinois Department of Transportation specifications. However, reports have indicated that some pavements that have utilized RAP as embankment material, such as reconstruction of the Jane Addams Memorial Tollway (I-90) in Illinois, have experienced excessive settlement soon after construction. In addition, the use of RAP in roadway embankments and as structural backfill has so far been only loosely specified in terms of maximum size, gradation, engineering properties, and acceptance.

To address these issues, the research team reviewed design and construction documents. They then procured RAP samples from five sources used by Illinois Tollway contractors and two conventional soils (as references) for laboratory experiments. The experiments included testing for basic soil/RAP characteristics, gradations, moisture-density relationships at different temperatures, permeability, and drainage. They also included one-dimensional consolidation tests, dynamic triaxial tests, and settlement analysis.

The results showed that RAP should not be used directly underneath the pavement drainage layer. In tests, the RAP samples exhibited significantly greater permeability than the two tested soils or a soil plus RAP mix, and when RAP was located immediately below the drainage layer, water drained into the RAP layer, which in turn collected the water and saturated the embankment soil under the RAP layer. Stress analysis results suggested that RAP should also not be used within the top 5 feet of a rigid pavement embankment or 8 feet of a flexible pavement embankment, nor immediately above underground concrete/metal structures or bedrock. In addition, RAP should not be used within the traffic load influence zone.

Consolidation tests showed that RAP should be compacted to 100 percent of its maximum dry density in accordance with the standard Proctor test method. It is also recommended that during design, settlement analysis should consider the potential settlement of embankment soil from its as-compacted condition to a saturated condition, as well potential settlement associated with fast-tracked construction of the RAP layer in the embankment.

Authors:

Haifang Wen

Mohammadreza Barzegar

Maziar Mivehchi

Idil Akin

Balasingam Muhunthan

WSU Department of Civil and Environmental Engineering

Tuncer Edil

UW-Madison Department of Civil and Environmental Engineering

Sponsor: Illinois State Toll Highway Authority